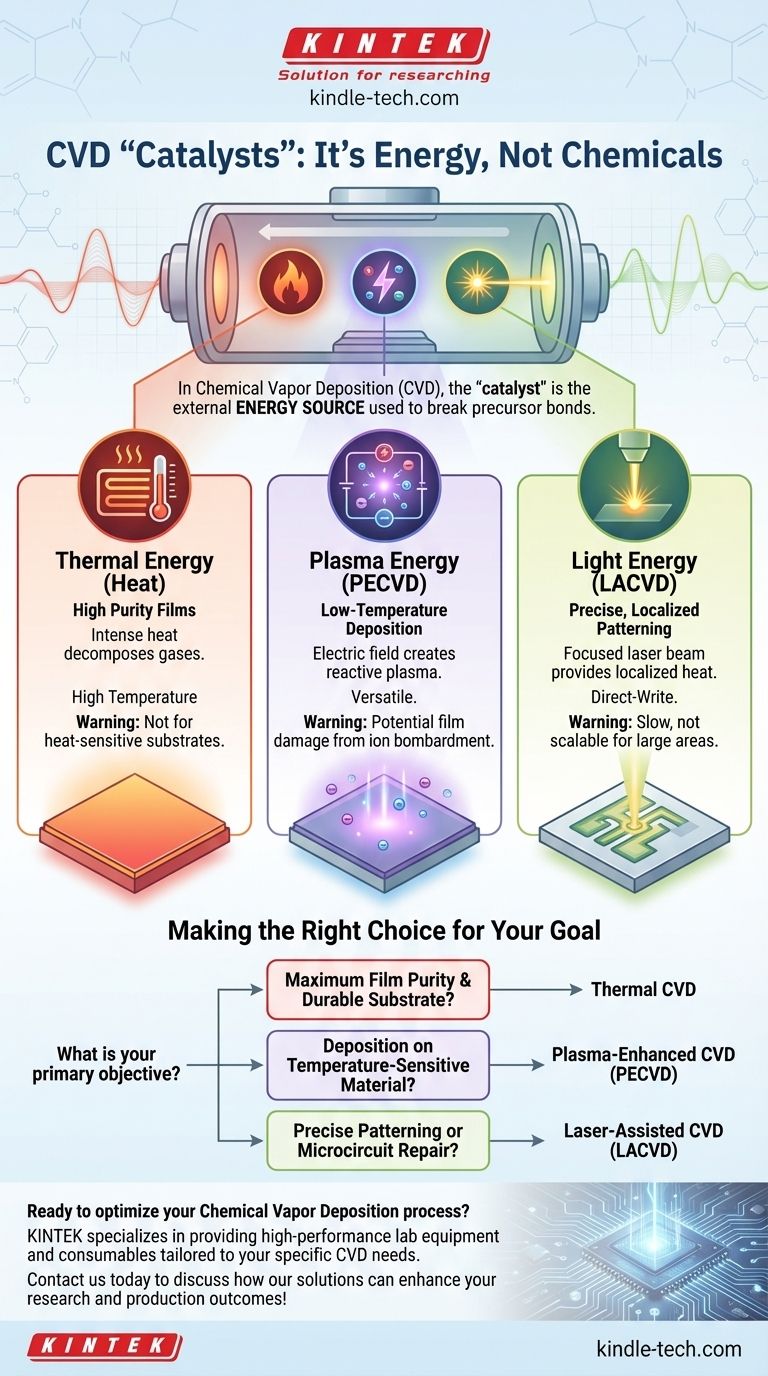

In Chemical Vapor Deposition (CVD), the "catalyst" is not a chemical substance but rather the external energy source used to initiate the reaction. This energy—most commonly in the form of heat, plasma, or light—breaks down the precursor gases and allows them to react and deposit a solid film onto a substrate. The specific type of energy used defines the CVD process and its capabilities.

The core principle to understand is that CVD reactions are driven by applied energy, not by traditional chemical catalysts. Choosing the right energy source—be it thermal, plasma, or photonic—is the fundamental decision that dictates the deposition temperature, film quality, and suitability for a specific application.

How CVD Reactions Are Initiated

Chemical Vapor Deposition is fundamentally a process of building a solid material from gaseous molecules (precursors). To make this happen, the chemical bonds in the precursor gases must be broken. This requires a significant input of energy, which serves the catalytic role of starting the deposition.

The Role of Thermal Energy (Heat)

The most common initiation method is thermal energy. In processes like Thermal CVD and Hot-Filament CVD, the entire chamber, including the substrate, is heated to very high temperatures.

This intense heat provides the energy needed for the precursor gases to decompose and react on the substrate surface. This method is known for producing very high-purity films, such as the polysilicon used in the solar industry.

The Role of Plasma Energy

Plasma-Enhanced CVD (PECVD) uses plasma instead of high heat as its primary energy source. An electric field is applied to the precursor gas, stripping electrons from the atoms and creating a highly reactive plasma.

This plasma state provides the energy to drive the chemical reactions at much lower temperatures than Thermal CVD. This makes PECVD ideal for depositing films on substrates that cannot withstand high heat.

The Role of Light Energy (Photons)

A more specialized method is Laser-Assisted CVD (LACVD). In this technique, a focused laser beam is directed at the substrate.

The intense light energy is absorbed in a very small area, providing localized heating that initiates the deposition reaction only where the laser is pointing. This allows for precise, direct-write patterning of materials.

Understanding the Trade-offs

The choice of energy source is not just about starting the reaction; it involves a series of critical trade-offs that impact the final product and the manufacturing process itself.

Heat: Purity vs. Substrate Limitations

Thermal CVD is the gold standard for film purity and quality. However, its reliance on extremely high temperatures means it is incompatible with temperature-sensitive substrates like plastics or certain electronic components, which would be damaged or destroyed.

Plasma: Versatility vs. Potential Damage

PECVD's low-temperature operation makes it incredibly versatile. The trade-off is that the high-energy ions within the plasma can sometimes bombard the growing film, potentially causing structural damage or introducing impurities, which may affect its performance.

Lasers: Precision vs. Scalability

LACVD offers unmatched precision, allowing for deposition on specific microscale locations without heating the entire substrate. This advantage, however, makes it a slow, serial process that is not practical for coating large areas, limiting its industrial scalability.

Making the Right Choice for Your Goal

Selecting the correct CVD method requires aligning the process capabilities with your primary objective.

- If your primary focus is maximum film purity for a durable substrate: Thermal CVD is the superior choice, provided your material can withstand the high temperatures.

- If your primary focus is depositing a film on a temperature-sensitive material: Plasma-Enhanced CVD (PECVD) is the only viable option, as it enables deposition at significantly lower temperatures.

- If your primary focus is depositing a precise pattern or repairing a microcircuit: Laser-Assisted CVD provides the localized control needed for these specialized tasks.

Ultimately, mastering CVD means understanding that the energy you introduce is the most powerful tool you have for controlling the process and its outcome.

Summary Table:

| CVD Method | Energy Source | Key Advantage | Key Limitation |

|---|---|---|---|

| Thermal CVD | Heat | High-purity films | High temperatures can damage sensitive substrates |

| Plasma-Enhanced CVD (PECVD) | Plasma | Low-temperature deposition | Potential plasma-induced film damage |

| Laser-Assisted CVD (LACVD) | Laser/Light | Precise, localized patterning | Slow, not scalable for large areas |

Ready to optimize your Chemical Vapor Deposition process? KINTEK specializes in providing high-performance lab equipment and consumables tailored to your specific CVD needs. Whether you require the high-purity results of Thermal CVD, the low-temperature versatility of PECVD, or the precision of LACVD, our experts can help you select the right solution. Contact us today to discuss how our solutions can enhance your research and production outcomes!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating