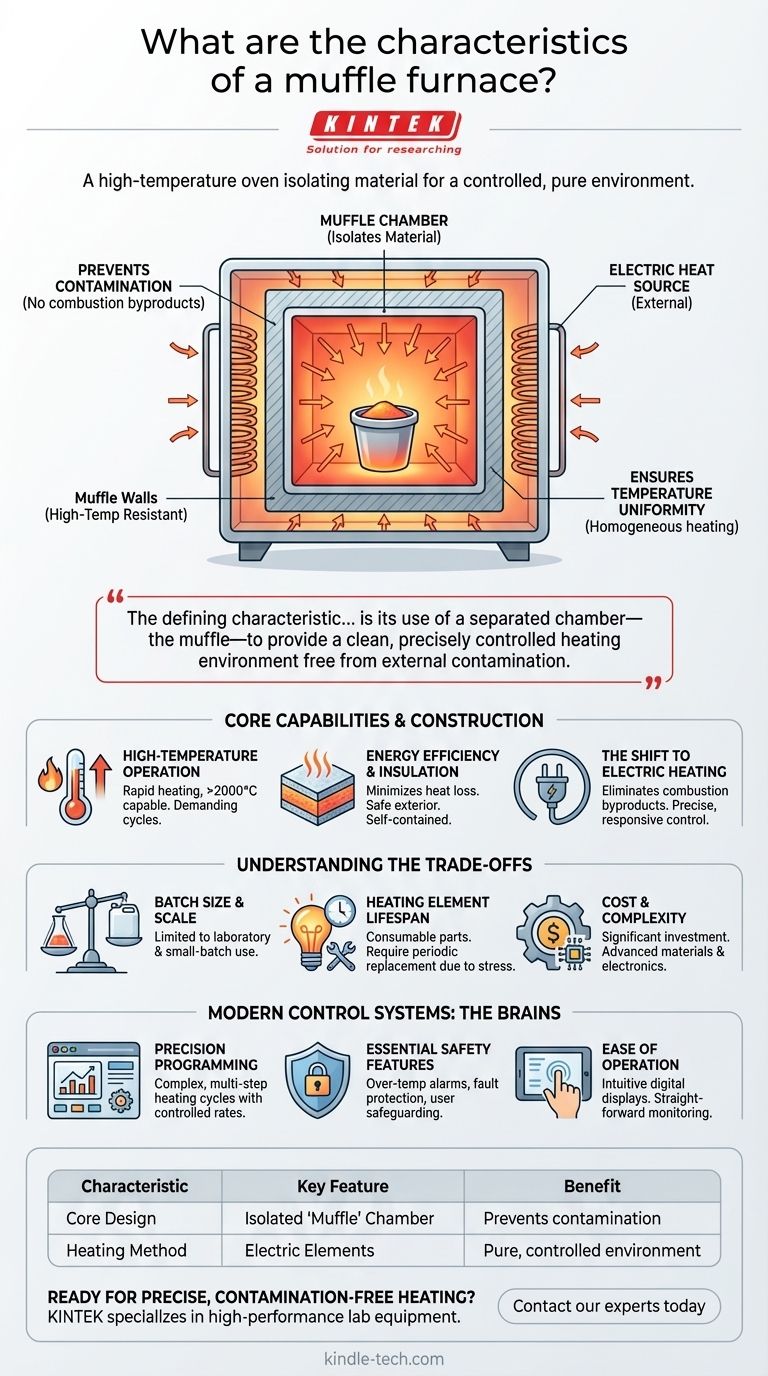

At its core, a muffle furnace is a high-temperature oven distinguished by a single, critical design principle: it isolates the material being heated from the direct heat source and any contaminants. This is achieved using an inner chamber, or "muffle," which ensures that the workpiece is heated in a controlled, pure environment, free from the byproducts of fuel combustion that would be present in a traditional furnace.

The defining characteristic of a muffle furnace is not just its ability to reach high temperatures, but its use of a separated chamber—the muffle—to provide a clean, precisely controlled heating environment free from external contamination.

The Defining Principle: The 'Muffle' Chamber

The entire purpose of a muffle furnace is built around its unique chamber design. Understanding this concept is key to understanding its value in technical applications.

What is a Muffle?

A muffle is an enclosed, sealed chamber made of high-temperature-resistant material. The material to be heated is placed inside this muffle.

The heat source (whether from fuel combustion or electric elements) heats the outside of the muffle. The heat then transfers through the muffle walls to the material inside, typically through a combination of radiant and convection heat.

Preventing Contamination

The primary benefit of this design is the prevention of contamination. In furnaces where fuel is burned directly, byproducts like soot, ash, and gases can settle on or react with the material being heated.

By separating the heating chamber from the combustion chamber, the muffle furnace guarantees that the workpiece is exposed only to the intended atmosphere, which is critical for sensitive materials research, electronics, and ceramics.

Ensuring Temperature Uniformity

The enclosed nature of the muffle helps create a highly uniform temperature environment. As the entire chamber radiates heat inward, it reduces hot spots and ensures the workpiece is heated homogeneously from all sides.

Core Capabilities and Construction

Beyond the muffle itself, several characteristics define the furnace's performance and suitability for different tasks.

High-Temperature Operation

Muffle furnaces are designed for rapid heating, temperature recovery, and cooling cycles. They are built to operate at very high temperatures, with some specialized models capable of exceeding 2000°C.

Energy Efficiency and Insulation

These furnaces are typically built as self-contained cabinets constructed with highly effective insulating materials. This design minimizes heat loss, making them more energy-efficient and ensuring the exterior remains safe to the touch.

The Shift to Electric Heating

Modern muffle furnaces overwhelmingly use electric heating elements, such as resistance wires, silicon carbon rods, or silicon-molybdenum rods.

Electric heating completely eliminates the byproducts of combustion, offering the purest possible heating environment. It also allows for significantly more precise and responsive temperature control compared to fuel-fired models.

Understanding the Trade-offs

While highly effective, muffle furnaces are not the solution for every heating application. Understanding their limitations is crucial for making an informed decision.

Batch Size and Scale

Muffle furnaces are most often used for laboratory-scale experiments, quality control testing, and small-batch production. Their enclosed design limits the size and volume of material that can be processed at one time.

Heating Element Lifespan

The high temperatures at which these furnaces operate place extreme stress on the electric heating elements. These elements are considered consumables and will require periodic replacement over the furnace's lifetime.

Cost and Complexity

The advanced materials required for the muffle and insulation, coupled with sophisticated electronic control systems, can make these furnaces a significant investment compared to simpler ovens or direct-fired furnaces.

The Brains of the Furnace: Modern Control Systems

The performance of a modern muffle furnace is heavily dependent on its control system. These systems provide the precision and safety required for technical work.

Precision Temperature Programming

Advanced controllers allow users to program complex heating cycles with multiple steps. This includes setting the rate of temperature increase (thermal gradient), holding at a specific temperature for a set time, and controlling the cooling rate.

Essential Safety Features

Modern units are equipped with critical safety mechanisms. These include over-current and over-voltage protection, leakage protection, and alarms for over-temperature conditions, safeguarding both the user and the furnace.

Ease of Operation

Despite their complexity, muffle furnaces are designed for ease of use. Digital displays and intuitive interfaces allow for straightforward programming and monitoring, with some advanced models offering remote control capabilities.

Making the Right Choice for Your Application

Selecting the correct muffle furnace requires matching its features to your specific goal.

- If your primary focus is material purity and research: Prioritize an electric furnace with an advanced, multi-segment programmable temperature controller.

- If your primary focus is small-batch industrial production: Look for a furnace with robust construction, proven energy efficiency, and comprehensive safety features.

- If your primary focus is reaching extreme temperatures: Verify the maximum temperature rating and confirm the type of heating element used, as some are better suited for higher heat ranges.

Ultimately, understanding these core characteristics empowers you to select and operate a muffle furnace that delivers the precise, controlled, and pure heating environment your work demands.

Summary Table:

| Characteristic | Key Feature | Benefit |

|---|---|---|

| Core Design | Isolated 'Muffle' Chamber | Prevents contamination from heat source |

| Heating Method | Electric Elements (Modern) | Ensures a pure, precisely controlled environment |

| Temperature | High-Temperature Operation (up to 2000°C+) | Suitable for demanding applications |

| Control | Advanced Programmable Controllers | Enables complex, repeatable heating cycles |

| Application | Laboratory & Small-Batch Use | Ideal for research, QA testing, and small production |

Ready to achieve precise, contamination-free heating in your lab?

KINTEK specializes in high-performance lab equipment, including a range of muffle furnaces designed for material research, quality control, and small-batch production. Our furnaces deliver the pure environment and precise temperature control your sensitive work demands.

Contact our experts today to find the perfect muffle furnace for your specific application and ensure superior results for your laboratory.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the role of high-temperature furnaces in red mud brick production? Master Slow-Burning for Superior Strength

- What is a box furnace? A Guide to Batch Thermal Processing for Labs & Industry

- What are muffle furnaces used for? Achieve Pure, High-Temperature Processing

- How do you control a muffle furnace? Master Precise Temperature Control for Your Lab

- What is the purpose of the ash content test? A Guide to Material Quality Control

- What is an oven furnace? Achieve Precise, Uniform Heat for Industrial & Lab Applications

- What is the role of high-temperature muffle or tube furnaces in LLZTO synthesis? Master Cubic Phase Ceramic Production

- What is the primary purpose of using a vacuum drying oven? Ensure Purity in Inconel 625/TiB2 Raw Materials