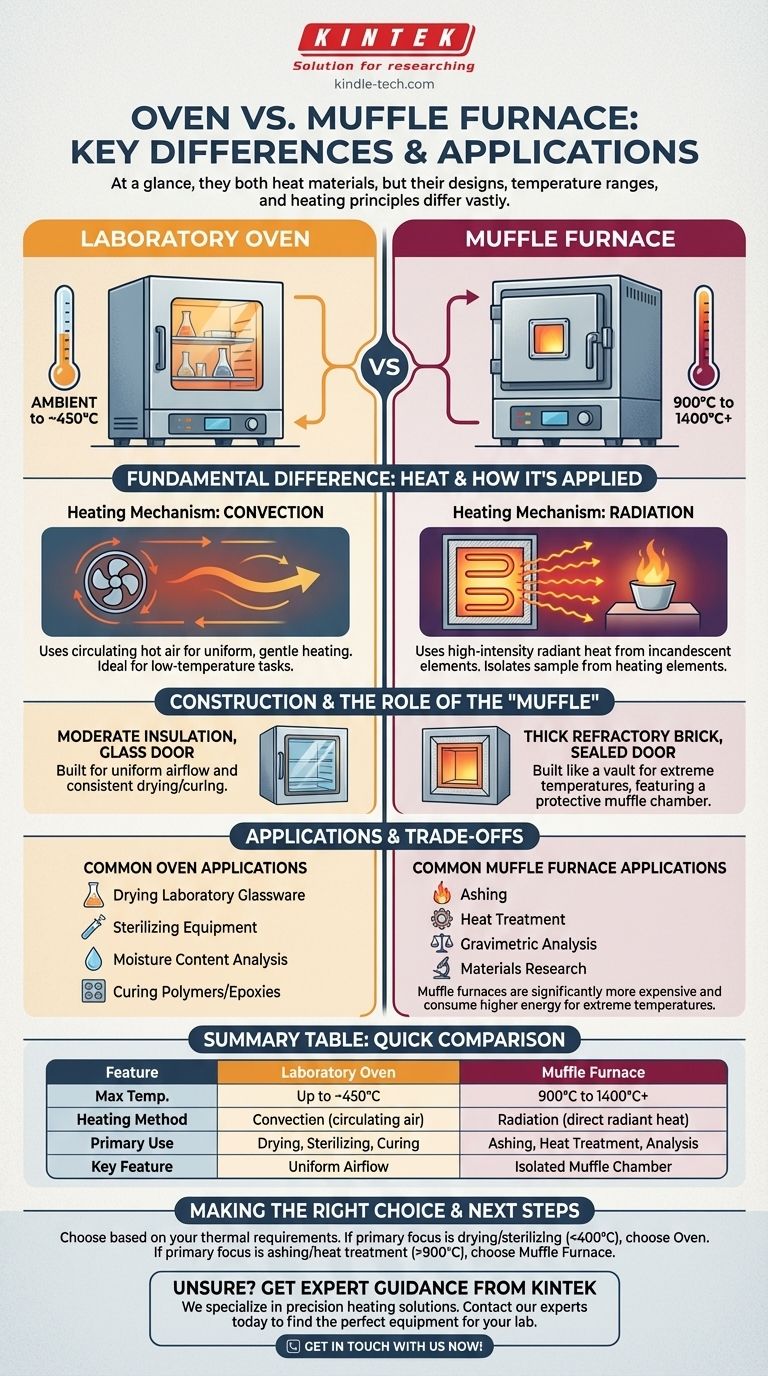

At a glance, an oven and a muffle furnace appear to serve the same function: heating materials. However, their design, capabilities, and fundamental heating principles are vastly different. The single most important distinction is their operating temperature range, which dictates their construction and intended applications. A laboratory oven typically operates from ambient temperature up to around 450°C, while a muffle furnace is built for high-temperature work, generally starting at 900°C and reaching 1400°C or higher.

The core difference lies in their heating method and purpose. An oven uses circulating hot air (convection) for low-temperature tasks like drying and sterilization. A muffle furnace uses contained, high-intensity radiant heat for processes like ashing or heat-treating metals, isolating the sample from the heating elements.

The Fundamental Difference: Heat and How It's Applied

The dramatic temperature gap between these two instruments is a direct result of their entirely different approaches to generating and delivering heat.

Temperature Range

An oven is designed for precision and uniformity at lower temperatures. Its range is suited for processes that would be damaged by extreme heat.

A muffle furnace is engineered specifically to create and contain extreme temperatures, enabling material phase changes, combustion, and high-temperature chemical reactions.

Heating Mechanism: Convection vs. Radiation

An oven almost always relies on convection. A heating element warms the air inside the chamber, and a fan circulates that air to ensure a uniform temperature throughout. This is ideal for gently and evenly heating a sample, such as when drying glassware.

A muffle furnace uses radiation. High-power heating coils (elements) line the walls of an insulation chamber. These elements become incandescent, radiating intense energy that heats the sample directly, much like the heat you feel from a glowing fire. There is no fan.

The Role of the "Muffle"

The term "muffle furnace" comes from the muffle, a protective inner chamber, typically made of high-temperature ceramic. This chamber isolates the material being heated from the actual heating elements.

This separation is critical. It prevents contamination of the sample by flakes from the heating elements and ensures the sample is heated by pure radiation, providing extreme temperature uniformity.

How Construction Dictates Function

The purpose of each device dictates every aspect of its physical construction, from the insulation to the door.

Oven Construction

Ovens are built with moderate insulation and often feature an inner glass door for observation. Their primary design focus is on maintaining uniform airflow for consistent drying, baking, or curing.

Muffle Furnace Construction

A muffle furnace is built like a vault for heat. It features thick, multi-layered walls of refractory brick and ceramic fiber insulation to safely contain extreme temperatures. The door is heavy, thick, and designed to create a tight seal to prevent heat loss and protect the operator.

Understanding the Applications and Trade-offs

Choosing the wrong instrument is not only inefficient but can destroy your sample or fail to achieve the desired result.

Common Oven Applications

Ovens are workhorses for low-temperature thermal processing. Common uses include:

- Drying laboratory glassware

- Sterilizing medical or lab equipment

- Determining the moisture content of a sample

- Curing polymers and epoxies

Common Muffle Furnace Applications

A muffle furnace is required when the goal is to fundamentally alter a material with intense heat. Key applications include:

- Ashing: Burning off all organic matter from a sample to determine inorganic content (e.g., mineral content in food).

- Heat Treatment: Altering the properties of metals and ceramics through processes like annealing, hardening, and tempering.

- Gravimetric Analysis: Separating compounds through high-temperature combustion.

- Materials Research: Testing the thermal properties and melting points of new materials.

The Energy and Cost Factor

The difference in capability comes with a significant difference in cost and energy consumption. Muffle furnaces are substantially more expensive to purchase and operate, consuming vast amounts of electricity to reach and maintain their target temperatures. Using one for a simple drying task would be highly inefficient.

Making the Right Choice for Your Process

Your choice should be guided entirely by the thermal requirements of your specific procedure.

- If your primary focus is drying, sterilizing, or low-temperature curing (below 400°C): An oven provides the necessary temperature control and uniform air circulation efficiently and economically.

- If your primary focus is ashing, heat treating metals, or any process requiring temperatures above 900°C: A muffle furnace is the only appropriate choice, providing the necessary heat intensity and a protected environment.

- If your goal is to analyze the inorganic content of a sample by burning away organics: You must use a muffle furnace for the ashing process.

Ultimately, choosing the correct instrument is about applying the right heating principle for your specific scientific or industrial goal.

Summary Table:

| Feature | Laboratory Oven | Muffle Furnace |

|---|---|---|

| Max Temperature | Up to ~450°C | 900°C to 1400°C+ |

| Heating Method | Convection (circulating hot air) | Radiation (direct radiant heat) |

| Primary Use | Drying, sterilizing, curing | Ashing, heat treatment, gravimetric analysis |

| Key Feature | Uniform airflow for gentle heating | Isolated muffle chamber for contamination-free high heat |

Unsure which heating equipment is right for your lab?

Choosing between an oven and a muffle furnace is critical for your process success and safety. KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision heating solutions.

We can help you:

- Select the ideal equipment based on your temperature requirements and application

- Ensure you get the right instrument for drying, sterilization, ashing, or heat treatment

- Optimize your lab's efficiency with the correct heating technology

Contact our experts today for personalized guidance and find the perfect heating solution for your laboratory. Get in touch with us now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the five common heat treatments of metals? Master the Processes for Precise Material Properties

- What is a muffle furnace in food analysis? A Guide to Precise Mineral Content Measurement

- What is the difference between sintering and fusing? Master the Key Thermal Processes for Your Materials

- How to use a muffle furnace in a laboratory? A Step-by-Step Guide to Safe, Precise Thermal Processing

- What is the heating mechanism of a muffle furnace? Achieve Clean, Uniform High-Temperature Processing