In essence, biomass conversion technologies are categorized into two primary families: thermochemical and biochemical pathways. Thermochemical methods use heat to break down biomass, including direct combustion for heat, gasification into fuel gas, and pyrolysis into bio-oil and biochar. Biochemical methods use microorganisms or enzymes to decompose the biomass, primarily through anaerobic digestion to create biogas or fermentation to produce liquid biofuels like ethanol.

The optimal biomass conversion technique is not a matter of which is universally "best," but which process is best suited to the specific type of biomass feedstock you have and the end product you need to create. The choice is fundamentally a matching problem between input, process, and desired output.

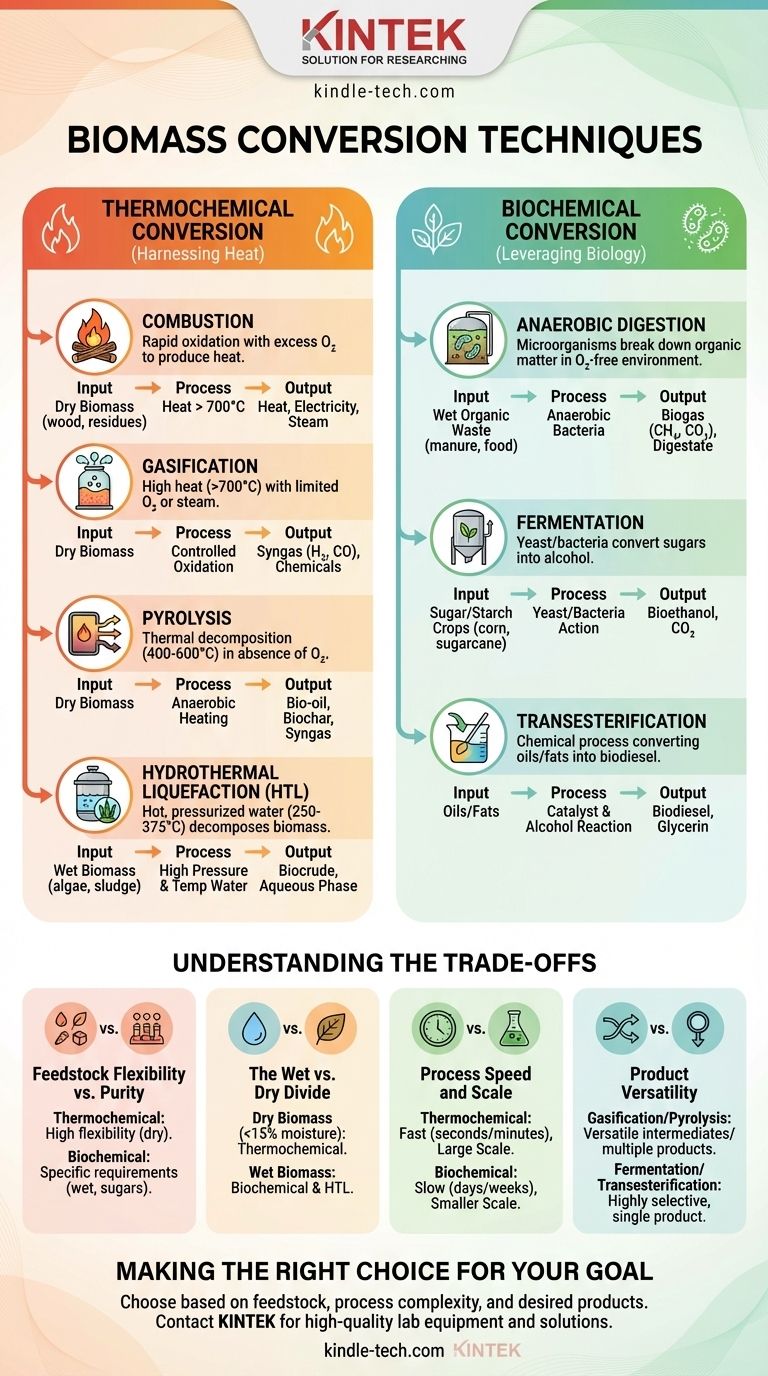

Thermochemical Conversion: Harnessing Heat

Thermochemical conversion uses heat and chemical reactions to break down the complex structures within biomass, such as cellulose, hemicellulose, and lignin. These processes are generally fast and can handle a wide variety of dry feedstocks.

Combustion

Combustion is the most direct and established method. It is the simple, rapid oxidation (burning) of biomass in the presence of excess oxygen to produce heat.

This heat can be used directly for industrial processes, to heat buildings, or to boil water to create steam that drives a turbine, generating electricity. This is the dominant technology for large-scale biomass power plants.

Gasification

Gasification involves heating biomass at high temperatures (over 700°C) with a controlled, limited amount of oxygen or steam.

Instead of fully burning, this process converts the solid biomass into a combustible gas mixture known as syngas (synthesis gas), primarily composed of hydrogen (H₂) and carbon monoxide (CO). Syngas is a versatile intermediate product that can be burned to generate electricity or further processed to produce liquid fuels and chemicals.

Pyrolysis

Pyrolysis is the thermal decomposition of biomass at high temperatures (400-600°C) in the complete absence of oxygen. The lack of oxygen prevents burning and instead breaks the material down into three distinct products.

The primary products are bio-oil (a dark, viscous liquid), biochar (a stable, carbon-rich solid), and syngas. The relative yield of these products can be controlled by the process speed; fast pyrolysis maximizes bio-oil, while slow pyrolysis maximizes biochar.

Hydrothermal Liquefaction (HTL)

HTL uses hot, pressurized water (250-375°C) to decompose biomass. Its key advantage is the ability to process wet biomass (like algae, manure, or sewage sludge) without the need for energy-intensive drying.

The process mimics the natural geological conditions that create crude oil, converting the biomass into a liquid biocrude that can be refined into fuels.

Biochemical Conversion: Leveraging Biology

Biochemical methods use the metabolic action of microorganisms (like bacteria and yeast) or enzymes to convert organic matter into energy. These processes operate at much lower temperatures than thermochemical methods and are ideal for feedstocks with high moisture and specific sugar or organic content.

Anaerobic Digestion

In an oxygen-free environment, anaerobic bacteria break down organic waste, such as food scraps, animal manure, or wastewater sludge.

This "digestion" process produces biogas, a mixture of methane (CH₄) and carbon dioxide (CO₂). This biogas can be burned for heat and power or purified into renewable natural gas (RNG) for injection into pipelines or use as vehicle fuel. The remaining solid is a nutrient-rich digestate that can be used as fertilizer.

Fermentation

Fermentation uses yeast or bacteria to convert the simple sugars in biomass into alcohol. It is the same fundamental process used to make beer and wine.

The most common application is producing bioethanol from sugar-rich crops (like sugarcane) or starchy crops (like corn). Research is focused on "cellulosic fermentation," which uses advanced enzymes to break down non-food woody biomass into sugars for ethanol production.

Transesterification

While technically a chemical process, transesterification is central to producing a major biofuel. It is the process used to convert oils and fats into biodiesel.

In this reaction, vegetable oils or animal fats are reacted with a short-chain alcohol (like methanol) in the presence of a catalyst. The output is biodiesel and a co-product, glycerin.

Understanding the Trade-offs

Choosing a conversion pathway involves critical trade-offs between the feedstock requirements, process complexity, and desired products.

Feedstock Flexibility vs. Purity

Gasification and pyrolysis are highly flexible, capable of processing nearly any form of dry organic material. However, fermentation is highly specific, requiring a clean stream of simple sugars.

The Wet vs. Dry Divide

This is the most critical factor. Thermochemical processes like pyrolysis and combustion require dry biomass (typically <15% moisture), and energy must be spent to dry the feedstock. In contrast, anaerobic digestion and HTL excel with wet biomass, avoiding this drying penalty.

Process Speed and Scale

Thermochemical processes are very fast, with reaction times measured in seconds or minutes, making them suitable for large, continuous industrial-scale facilities. Biochemical processes are much slower, taking days or weeks to complete a batch, and are often deployed at smaller, more distributed scales.

Product Versatility

Gasification produces syngas, an incredibly versatile intermediate that can lead to electricity, hydrogen, or synthetic fuels. Pyrolysis yields three distinct products (oil, gas, char) simultaneously. In contrast, fermentation and transesterification are highly selective, designed to maximize the output of a single product like ethanol or biodiesel.

Making the Right Choice for Your Goal

Your decision must be driven by your starting material and your end objective. There is no single best technology, only the right tool for the job.

- If your primary focus is generating utility-scale electricity from dry wood or agricultural residues: Direct combustion is the most mature and cost-effective pathway.

- If your primary focus is converting wet organic waste like manure or food scraps into energy: Anaerobic digestion is the ideal solution to produce biogas while also creating a valuable fertilizer co-product.

- If your primary focus is producing liquid transportation fuel: Your choice depends on the feedstock. Use fermentation for corn and sugar, transesterification for waste oils, and pyrolysis or HTL for mixed or woody biomass.

- If your primary focus is creating valuable co-products like soil-improving biochar: Slow pyrolysis is the specific process designed to maximize this solid carbon product.

Ultimately, understanding the interplay between feedstock, process, and product empowers you to navigate the bioenergy landscape effectively.

Summary Table:

| Conversion Type | Key Process | Ideal Feedstock | Primary Output(s) |

|---|---|---|---|

| Thermochemical | Combustion | Dry biomass (wood, residues) | Heat, Electricity |

| Thermochemical | Gasification | Dry biomass | Syngas (H₂, CO) |

| Thermochemical | Pyrolysis | Dry biomass | Bio-oil, Biochar, Syngas |

| Thermochemical | Hydrothermal Liquefaction (HTL) | Wet biomass (algae, sludge) | Biocrude |

| Biochemical | Anaerobic Digestion | Wet organic waste (manure, food) | Biogas (CH₄, CO₂) |

| Biochemical | Fermentation | Sugar/Starch crops (corn, sugarcane) | Bioethanol |

| Biochemical/Chemical | Transesterification | Oils/Fats | Biodiesel |

Ready to implement the ideal biomass conversion solution for your lab or operation?

At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored for bioenergy research and development. Whether you're exploring pyrolysis for biochar production, optimizing anaerobic digestion, or scaling up gasification processes, our expertise and reliable equipment can help you achieve accurate and efficient results.

Contact us today to discuss how KINTEK can support your biomass conversion projects and help you select the right technology for your specific feedstock and energy goals.

Visual Guide

Related Products

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the function of a hydrothermal reactor? Optimize Core-Shell Polymer-Metal Oxide Membranes

- Why use PPL-Lined Autoclaves for Vanadium Dioxide Nanorods? Achieve Pure Crystallization at 280°C

- What is the role of a high-pressure hydrothermal autoclave in the synthesis of MgAlCe-LDH? Optimize Crystal Growth

- What is the function of a Teflon-lined stainless steel autoclave in rGO/TiO2 synthesis? Key Role in Nanocomposites

- What is the function of high-pressure autoclave reactors in hydrothermal synthesis? Optimize Nano-Oxide Growth Today.