The primary techniques for synthesizing carbon nanotubes (CNTs) are arc discharge, laser ablation, and chemical vapor deposition (CVD). While the first two methods were foundational in early research, CVD has become the dominant process for commercial-scale production due to its superior control and scalability.

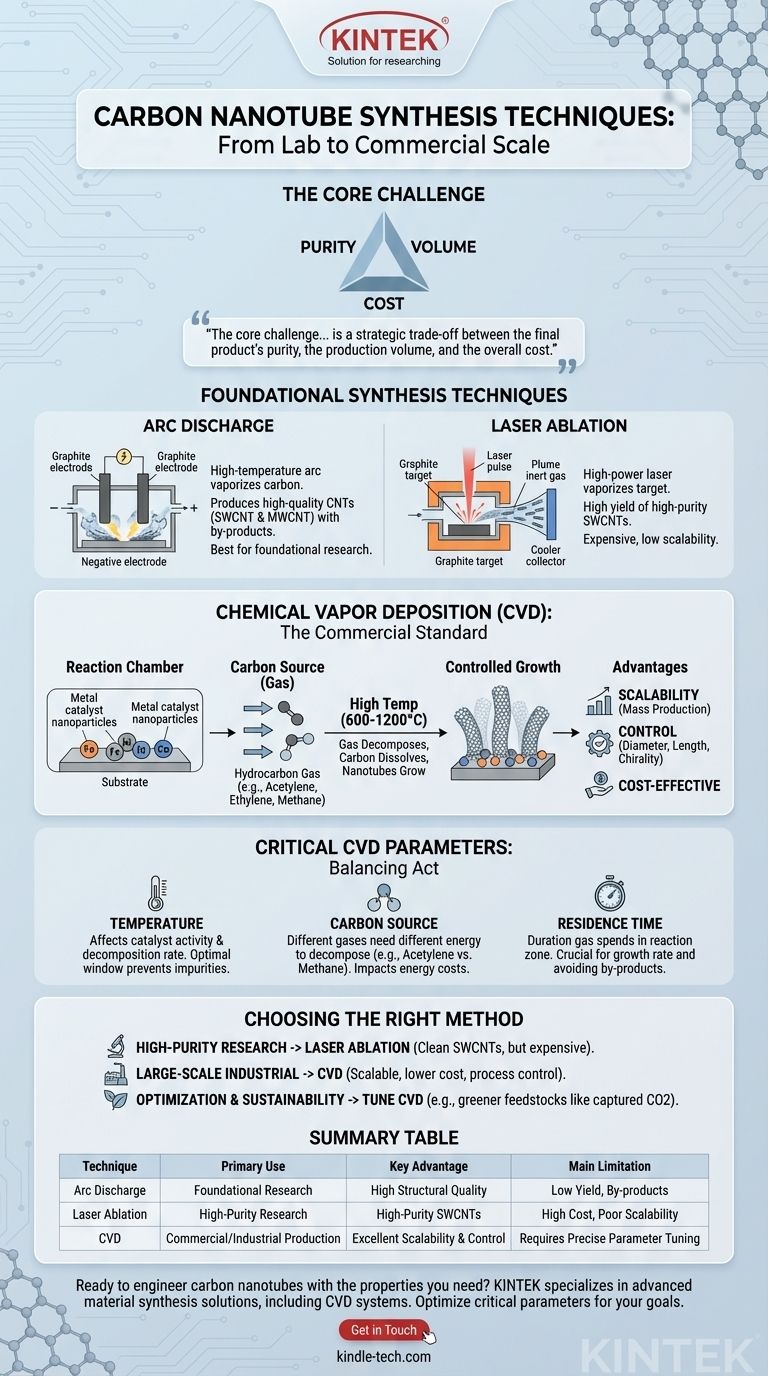

The core challenge in carbon nanotube synthesis is not simply creating them, but choosing a method that aligns with a specific goal. The decision is a strategic trade-off between the final product's purity, the production volume, and the overall cost.

The Foundational Synthesis Techniques

The earliest methods for producing CNTs rely on high-energy processes to vaporize carbon. Though less common for large-scale production today, they remain relevant for specific research applications where purity is paramount.

Arc Discharge

This method involves creating a high-temperature electric arc between two graphite electrodes. The intense heat vaporizes the carbon from the positive electrode.

The vaporized carbon then re-condenses in a controlled atmosphere, forming nanotubes on the negative electrode. This technique can produce both single-walled and multi-walled CNTs of high structural quality, but often in a mixture with other carbon by-products.

Laser Ablation

In laser ablation, a high-power laser is aimed at a graphite target within a high-temperature furnace. The laser pulse vaporizes the graphite, creating a plume of hot carbon atoms.

An inert gas flows through the chamber, carrying the carbon atoms to a cooler collector where they self-assemble into nanotubes. This method is known for producing a high yield of high-purity single-walled CNTs but is expensive and does not scale easily.

Chemical Vapor Deposition (CVD): The Commercial Standard

CVD is the most widely used method for industrial CNT production because it offers a high degree of control over the final product at a lower cost and higher volume.

The CVD Process Explained

The CVD process introduces a hydrocarbon gas (the carbon source) into a reaction chamber containing a substrate coated with metal catalyst nanoparticles, typically iron, nickel, or cobalt.

At high temperatures (600-1200°C), the hydrocarbon gas decomposes, and the carbon atoms dissolve onto the surface of the catalyst particles. The nanotubes then grow from these catalyst sites.

Why CVD Dominates

The primary advantage of CVD is its scalability. The process can be run continuously and adapted for large-area substrates, making it ideal for mass production.

Furthermore, by carefully controlling the process parameters, manufacturers can influence the nanotubes' diameter, length, and even chirality, which is difficult with other methods.

Understanding the Trade-offs and Critical Parameters

The success of any synthesis technique, especially CVD, depends on meticulously managing the operating conditions. Each parameter represents a lever that can be adjusted to optimize for yield, quality, or cost.

The Impact of Temperature

Temperature directly affects catalyst activity and the decomposition rate of the carbon source. An optimal temperature window is crucial for achieving high-quality growth without creating excessive amorphous carbon or other impurities.

Choosing a Carbon Source

Different hydrocarbon gases require different amounts of energy to decompose. For example, acetylene can be a direct CNT precursor, while ethylene and methane require more energy for thermal conversion.

This choice directly impacts the energy costs and efficiency of the synthesis process.

The Importance of Residence Time

Residence time is the duration the carbon source gas spends in the reaction zone. If it's too short, the carbon source is wasted; if it's too long, by-products can accumulate and terminate nanotube growth.

Maintaining an optimal residence time is a critical balancing act for achieving a high and consistent growth rate.

Making the Right Choice for Your Goal

Selecting a synthesis method requires a clear understanding of your end goal, as each technique is tailored to different outcomes.

- If your primary focus is high-purity samples for fundamental research: Laser ablation is often preferred for its ability to produce clean, single-walled nanotubes, despite its high cost and low yield.

- If your primary focus is large-scale industrial or commercial applications: Chemical Vapor Deposition (CVD) is the only practical choice due to its scalability, lower cost, and process control.

- If your primary focus is process optimization and sustainability: Investigate tuning CVD parameters (like using greener feedstocks such as captured CO2 or pyrolyzed methane) to reduce costs and environmental impact.

Ultimately, mastering carbon nanotube synthesis is about using these techniques not just to produce a material, but to engineer one with specific properties for a desired application.

Summary Table:

| Technique | Primary Use | Key Advantage | Main Limitation |

|---|---|---|---|

| Arc Discharge | Foundational Research | High Structural Quality | Low Yield, By-products |

| Laser Ablation | High-Purity Research | High-Purity SWCNTs | High Cost, Poor Scalability |

| Chemical Vapor Deposition (CVD) | Commercial/Industrial Production | Excellent Scalability & Control | Requires Precise Parameter Tuning |

Ready to engineer carbon nanotubes with the properties you need?

Navigating the trade-offs between purity, volume, and cost is complex. KINTEK specializes in lab equipment and consumables for advanced material synthesis, including Chemical Vapor Deposition (CVD) systems. Our expertise can help you optimize critical parameters like temperature, carbon source, and residence time to achieve your specific research or production goals.

Contact us today to discuss how our solutions can enhance your carbon nanotube synthesis process.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods