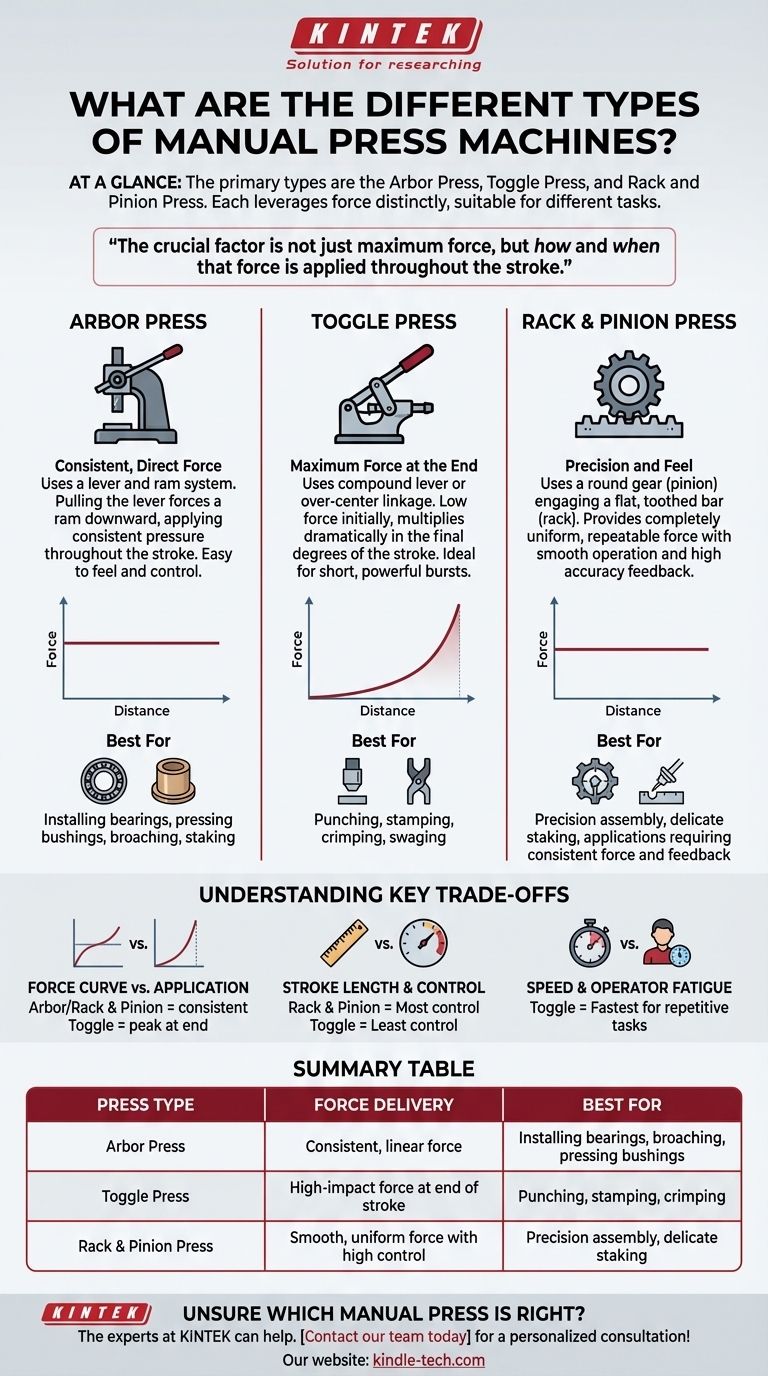

At a glance, the primary types of manual press machines are categorized by their mechanical action: the Arbor Press, the Toggle Press, and the Rack and Pinion Press. Each design leverages force in a distinct way, making them suitable for very different tasks, from applying consistent pressure to delivering a high-impact force at a single point.

The crucial factor in selecting a manual press is not just its maximum force rating, but understanding how and when that force is applied throughout the stroke. This mechanical profile is what separates a tool that works from a tool that excels.

How Mechanical Advantage Defines a Press

The purpose of any manual press is to multiply the operator's effort into a much greater output force. The internal mechanism—be it a simple lever, a compound linkage, or a gear system—determines how that force multiplication occurs.

Understanding this principle is the first step in choosing the right tool. You are not just buying tonnage; you are buying a specific force delivery system tailored to a particular kind of work.

Exploring the Primary Manual Press Types

Each major type of manual press offers a unique force curve and operational feel.

The Arbor Press: Consistent, Direct Force

An arbor press uses a lever and ram system. Pulling the lever forces a square or round ram downward, applying a consistent amount of pressure throughout the entire length of the stroke.

This design provides a direct, linear force that is easy to feel and control. It is the workhorse for tasks that require steady pressure.

Common applications include installing or removing bearings, pressing in bushings, broaching keyways, and general staking or riveting where force needs to be applied over a distance.

The Toggle Press: Maximum Force at the End

A toggle press uses a compound lever or over-center linkage. This mechanism generates relatively low force for the majority of the handle's travel, then multiplies it dramatically in the final few degrees of the stroke.

Think of it like snapping your knee straight; the greatest power is exerted at the very end of the motion. This makes it ideal for operations that require a short, powerful burst of force.

This high final force is perfect for punching, stamping, crimping electrical terminals, and swaging operations where the work is done in a single, decisive action.

The Rack and Pinion Press: Precision and Feel

This press uses a round gear (the pinion) that engages with a flat, toothed bar (the rack). Turning the lever rotates the pinion, driving the rack and attached ram up or down.

This mechanism provides a completely uniform and repeatable force for the entire stroke. It is known for its smooth operation and exceptional feel, allowing the operator to sense the pressure being applied with high accuracy.

The Rack and Pinion press excels in precision assembly, delicate staking jobs, and any application where consistent, repeatable force and operator feedback are critical.

Understanding the Key Trade-offs

Choosing a press involves balancing force, precision, and speed. No single press is best for every job.

Force Curve vs. Application

The most significant trade-off is the force curve. An arbor press provides its full force potential at any point, while a toggle press saves its peak force for the very end.

Using a toggle press for a task like seating a long bearing would be inefficient and difficult, as the necessary force is required over a distance. Conversely, using an arbor press for punching might require excessive operator effort compared to a toggle press.

Stroke Length and Control

Rack and Pinion presses offer the most control over the entire stroke, making them ideal for tasks where the ram depth must be precise.

Arbor presses offer good control but can feel less refined. Toggle presses offer the least control over stroke depth, as their action is designed to "bottom out" with maximum force.

Speed and Operator Fatigue

For highly repetitive tasks like stamping or crimping, the short, quick action of a toggle press is often the fastest and most ergonomic choice, reducing operator fatigue over a long shift.

Making the Right Choice for Your Application

Select your press based on the mechanical requirements of your primary task.

- If your primary focus is installing bearings, broaching, or seating parts: Choose an Arbor Press for its consistent, linear force delivery.

- If your primary focus is stamping, punching, or crimping: Select a Toggle Press to achieve maximum impact force at the end of the stroke with minimal effort.

- If your primary focus is precision assembly or delicate work requiring feedback: A Rack and Pinion Press will provide the best control and repeatability.

By matching the machine's mechanical advantage to your specific task, you ensure precision, efficiency, and the highest quality result.

Summary Table:

| Press Type | Force Delivery | Best For |

|---|---|---|

| Arbor Press | Consistent, linear force | Installing bearings, broaching, pressing bushings |

| Toggle Press | High-impact force at end of stroke | Punching, stamping, crimping |

| Rack & Pinion Press | Smooth, uniform force with high control | Precision assembly, delicate staking |

Unsure which manual press is right for your specific application? The experts at KINTEK can help. As a specialist in lab equipment and consumables, we understand the precision and reliability required for your work. We can guide you to the perfect press for your needs, ensuring efficiency and high-quality results. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- How is a laboratory hydraulic press used for stainless steel surface modification? Prevent Organic Acid Corrosion

- Why are precision powder pellet dies and hydraulic presses required for Magnéli phase titanium oxide granulation?

- Is a hydraulic press better than an electric press? Choose the Right Tool for Maximum Force or Precision

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing

- What is the difference between EDS and XRF? EDS for Microanalysis, XRF for Bulk Analysis

- What is the unit of pressure in a hydraulic press? Understanding PSI, Tons, and Force

- How are laboratory hydraulic presses applied in thin film testing? Optimize Adhesion and Stress Analysis

- What is an example of a mechanical press? Discover the Power of Stamping Presses for High-Volume Production