In short, no. While the term "hydraulic" derives from the Greek word for water, modern hydraulic presses do not use water as their power-transmitting fluid. They almost universally rely on specially formulated hydraulic oil. This is a critical engineering choice made for reasons of longevity, performance, and reliability.

The power of a hydraulic press comes not from the type of fluid used, but from the fluid's incompressibility. Oil is the standard choice because it lubricates components, prevents corrosion, and withstands high temperatures—properties water severely lacks.

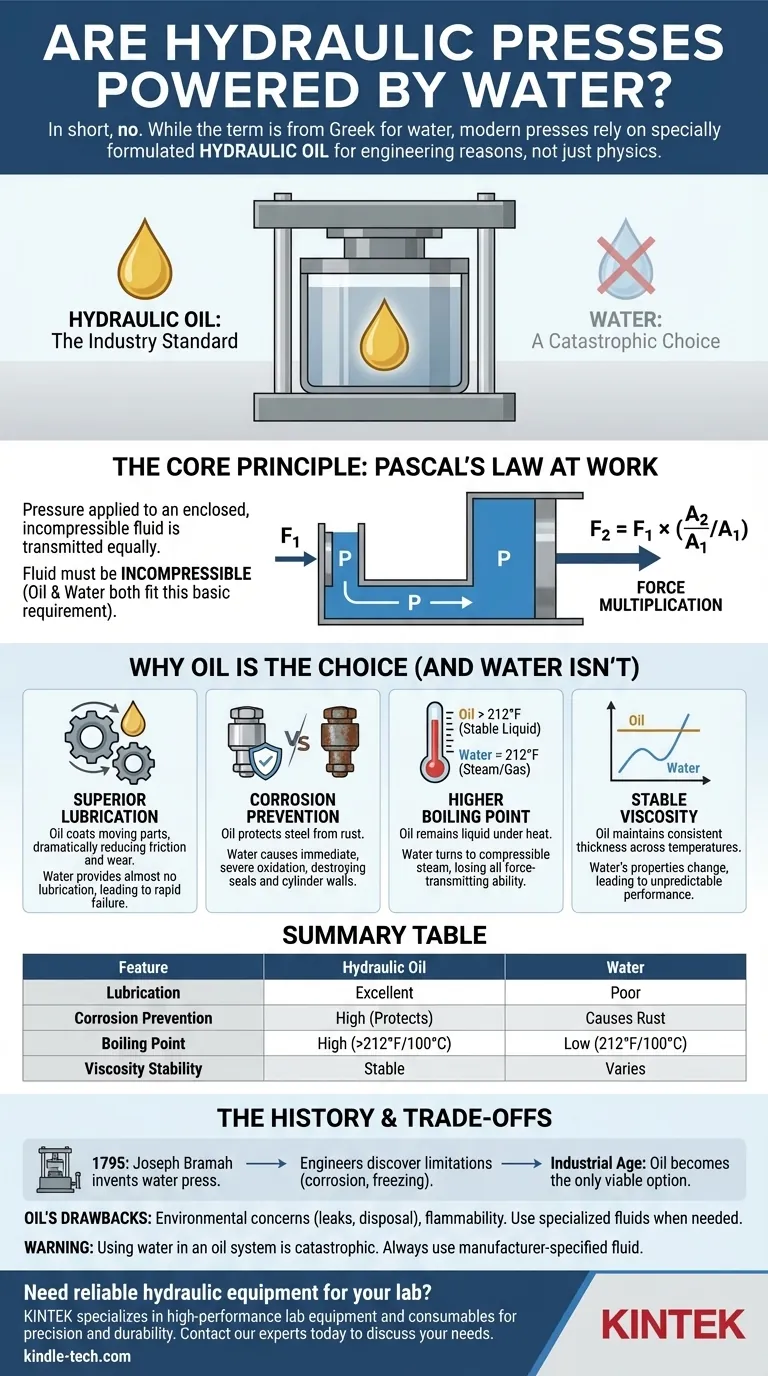

The Core Principle: Pascal's Law at Work

To understand why the fluid type is a practical detail rather than a physical necessity, you must first understand the principle that makes these machines possible.

What is Pascal's Law?

Pascal's Law is the foundational principle of hydraulics. It states that pressure applied to an enclosed, incompressible fluid is transmitted equally and undiminished to every portion of the fluid and the walls of the containing vessel.

How This Creates Force Multiplication

Imagine a sealed system with two pistons: one small and one large. If you apply a small amount of force to the small piston, it creates a certain pressure within the fluid.

According to Pascal's Law, this exact same pressure is applied to the much larger piston. Because the second piston has a vastly larger surface area, the resulting output force is multiplied enormously. This is how a small electric motor can generate thousands of tons of pressing force.

The Role of the Fluid

The only requirement for the fluid in this system is that it must be incompressible. Both water and oil fit this basic physical requirement. The decision to use one over the other is therefore based entirely on their secondary engineering properties.

Why Oil is the Industry Standard (and Water Isn't)

While water could theoretically work in a textbook physics problem, it would be a catastrophic choice for a real-world industrial machine used for operations like forging or blanking.

Superior Lubrication

A hydraulic press contains many moving parts, such as pistons, seals, and valves, all machined to tight tolerances. Hydraulic oil is an excellent lubricant, coating these parts to dramatically reduce friction and wear. Water provides almost no lubrication, which would lead to rapid component seizure and failure.

Corrosion Prevention

Hydraulic systems are made almost entirely of steel. Exposing these precision-machined internal components to water would cause immediate and severe rust (oxidation). This corrosion would destroy seals, score cylinder walls, and quickly render the press inoperable. Oil, by contrast, displaces water and protects metal surfaces from corrosion.

Higher Boiling Point

The act of compressing a fluid and the friction of its movement generates significant heat. Water boils at 212°F (100°C), turning into steam. Steam is a gas and is highly compressible, meaning the system would lose all ability to transmit force. Hydraulic oils are engineered with much higher boiling points, ensuring they remain in a stable, incompressible liquid state even under heavy load.

Stable Viscosity

The viscosity (or thickness) of a fluid affects how it flows and transmits power. Hydraulic oils are designed to maintain a relatively stable viscosity across a wide range of operating temperatures. Water's properties change more dramatically with temperature, which would lead to inconsistent and unpredictable press performance.

Understanding the Trade-offs

Choosing the right fluid is a decision based on balancing ideal physics with messy reality. There are no perfect solutions, only optimized ones.

The History of Water Hydraulics

The very first hydraulic press, invented by Joseph Bramah in 1795, did use water. However, engineers quickly discovered the severe limitations of corrosion and freezing. As industrial technology advanced, oil-based systems became the only viable option for high-performance machinery.

The Downside of Hydraulic Oil

Oil is not without its drawbacks. The primary concern is environmental. Leaks can contaminate soil and water, and used oil must be disposed of as hazardous waste. Additionally, standard mineral oil is flammable, creating a fire risk in certain environments, though specialized fire-resistant hydraulic fluids are available.

What Happens if You Use the Wrong Fluid?

Using water in a system designed for oil would be catastrophic. It would lead to a rapid loss of lubrication, component corrosion, seal degradation, and ultimately, a complete and expensive system failure. Always use the specific type of hydraulic fluid recommended by the machine's manufacturer.

Making the Right Choice for Your System

Understanding this distinction is key to operating and maintaining any hydraulic equipment safely and effectively.

- If your primary focus is understanding the physics: Remember that force multiplication comes from Pascal's law and an incompressible fluid, not the specific fluid itself.

- If your primary focus is practical engineering: Always use the manufacturer-specified hydraulic oil to ensure proper lubrication, prevent corrosion, and maintain system integrity.

- If your primary focus is safety and environment: Be aware of the risks of oil leaks and have proper containment and disposal procedures in place for all hydraulic fluids.

Ultimately, the hydraulic press is a testament to how a simple physical principle is refined through smart engineering to become a cornerstone of modern industry.

Summary Table:

| Feature | Hydraulic Oil | Water |

|---|---|---|

| Lubrication | Excellent | Poor |

| Corrosion Prevention | High | Causes rust |

| Boiling Point | High (>212°F/100°C) | Low (212°F/100°C) |

| Viscosity Stability | Stable across temperatures | Varies with temperature |

Need reliable hydraulic equipment for your lab or industrial application? KINTEK specializes in high-performance lab equipment and consumables, ensuring your hydraulic systems operate with precision and durability. Our expertise helps you avoid costly mistakes and maximize efficiency. Contact our experts today to discuss your specific needs and discover the right solutions for your laboratory.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- Why was the hydraulic press important? Unlocking Unprecedented Industrial Power

- What is the difference between rolling and bending? Choose the Right Metal Forming Process

- What is the function of a laboratory hydraulic press in sulfide battery prep? Master Densification & Interfacial Fusion

- Is pressure constant in a hydraulic press? Unlock the Power of Force Multiplication

- What is the primary purpose of a laboratory hydraulic press for EIS testing on RPPO? Ensure Reliable Data Accuracy

- What is a pelletizing machine? Transform Raw Materials into High-Value Pellets

- How much does a small hydraulic press cost? Find the Right Tonnage for Your Budget

- What is a hydraulic jack? The Simple Physics of Lifting Heavy Loads