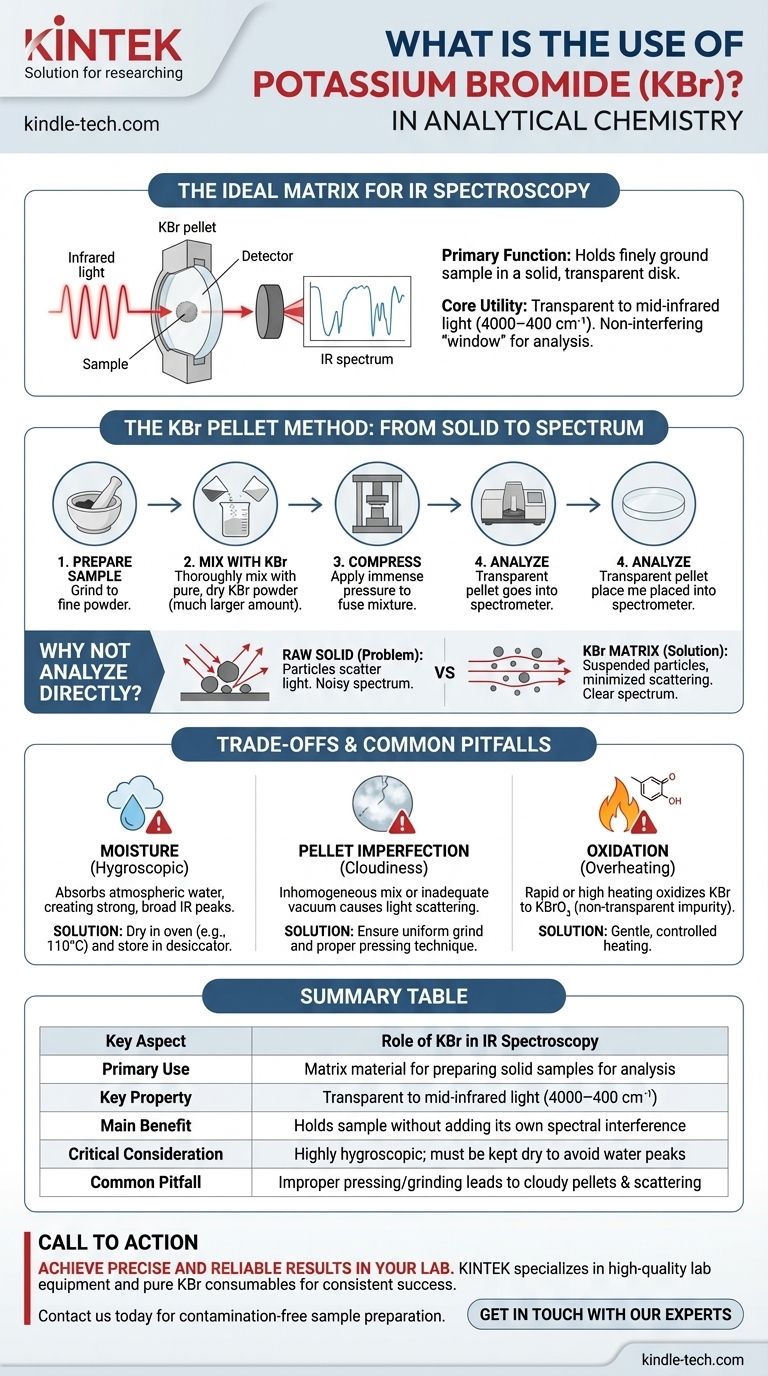

In analytical chemistry, Potassium Bromide (KBr) is most commonly used as an ideal matrix material for preparing solid samples for infrared (IR) spectroscopy. Its primary function is to hold a finely ground sample in a solid, transparent disk that does not interfere with the infrared light used for analysis.

The core utility of KBr stems from its unique properties: it is transparent to mid-infrared radiation and can be pressed into a solid, glass-like pellet. This allows it to act as a perfect, non-interfering "window" through which a solid sample's chemical fingerprint can be accurately measured.

The Role of KBr in Infrared Spectroscopy

To understand the use of KBr, you must first understand the challenge of analyzing solid materials with IR spectroscopy. The technique works by passing infrared light through a sample and measuring which frequencies are absorbed, revealing the types of chemical bonds present.

A Transparent Window for IR Light

Most materials, including solvents and glasses, absorb infrared light. If you were to suspend your sample in a substance that also absorbs IR, you would be unable to distinguish the sample's signal from the background noise.

KBr is exceptional because it does not have any significant absorption bands in the standard mid-IR range (4000–400 cm⁻¹). This infrared transparency makes it the perfect medium to hold a sample without adding its own spectral information.

The KBr Pellet Method

The most common application is the KBr pellet method. This involves a precise preparation process to turn an opaque, solid sample into a form suitable for analysis.

First, a tiny amount of the solid sample is ground into an extremely fine powder. This powder is then thoroughly mixed with a much larger amount of pure, dry KBr powder.

Finally, this mixture is placed in a die and compressed under immense pressure (several tons) using a hydraulic press. This process fuses the KBr particles into a thin, translucent or transparent disk, or pellet, with the sample particles uniformly dispersed within it. This pellet is then placed directly into the spectrometer.

Why Not Analyze the Solid Directly?

Attempting to analyze a raw solid powder or crystal often fails. The particles are typically too large and irregularly shaped, causing them to scatter most of the infrared light instead of allowing it to pass through.

By suspending the finely ground sample in the KBr matrix, this light scattering is minimized, resulting in a much cleaner and more interpretable spectrum.

Understanding the Trade-offs and Common Pitfalls

While the KBr method is powerful, its success depends entirely on proper technique. The properties that make KBr useful also introduce specific challenges that must be managed.

The Critical Issue of Moisture

KBr is highly hygroscopic, meaning it readily absorbs water moisture directly from the atmosphere. Water has very strong and broad absorption bands in the IR spectrum.

If your KBr is not perfectly dry, these water peaks will appear in your final spectrum, potentially obscuring important signals from your actual sample. This is why KBr must be dried in an oven (e.g., at 110 °C for several hours) and stored in a desiccator.

The Risk of Pellet Imperfection

An ideal KBr pellet is clear and uniform. A poor-quality pellet, often appearing cloudy or brittle, will scatter light and degrade the quality of the spectrum.

This is often caused by two factors: an inhomogeneous mix of the sample and KBr, or an inadequate vacuum during pressing. Trapped air and moisture pockets lead to a fragile pellet that produces a noisy, unreliable result.

The Danger of Oxidation

Care must be taken when drying KBr. Heating it too rapidly or at excessively high temperatures can cause it to oxidize into potassium bromate (KBrO₃).

This impurity is not transparent to IR light and can add unwanted peaks to your spectrum, compromising the analysis. Gentle, controlled heating is essential.

Making the Right Choice for Your Analysis

Your goal dictates how you should approach the KBr method. Success is not just about following steps, but understanding the principles behind them.

- If your primary focus is accuracy: Meticulously dry your KBr and grind your sample as finely as possible to ensure a clean, interference-free spectrum.

- If your primary focus is repeatability: Standardize your sample-to-KBr ratio and grinding time to ensure every pellet is prepared with consistent particle size and dispersion.

- If you are troubleshooting a poor spectrum: First, look for the broad, characteristic peaks of water around 3400 cm⁻¹ and 1640 cm⁻¹; their presence almost always indicates your KBr was contaminated with moisture.

Mastering the KBr pellet technique transforms an otherwise difficult solid sample into a source of clear and valuable analytical data.

Summary Table:

| Key Aspect | Role of KBr in IR Spectroscopy |

|---|---|

| Primary Use | Matrix material for preparing solid samples for analysis |

| Key Property | Transparent to mid-infrared light (4000–400 cm⁻¹) |

| Main Benefit | Holds sample without adding its own spectral interference |

| Critical Consideration | Highly hygroscopic; must be kept dry to avoid water peaks in spectrum |

| Common Pitfall | Improper pressing or grinding leads to cloudy pellets and light scattering |

Achieve precise and reliable results in your lab. The KBr pellet method is fundamental for accurate solid sample analysis via IR spectroscopy. KINTEK specializes in providing the high-quality lab equipment and consumables, like pure KBr powder and hydraulic presses, that your laboratory needs for consistent success. Contact us today to discuss how our solutions can enhance your analytical workflow and ensure contamination-free sample preparation.

Get in touch with our experts!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What happens after the HPHT growth cycle is complete and what shapes can the resulting diamonds have? Expert Analysis

- What is the objective of using a pellet press for pre-pressing powder samples? Enhance Density and Prevent Deformation

- What role does a laboratory hydraulic press play in the preparation of ferrotitanium oxide precursors? Key Functions

- What is the limitation of XRF? Understanding the Key Constraints for Accurate Analysis

- Why are hydraulic presses required when studying FATT50? Precision Tools for Grain Refinement & Impact Toughness

- What is the primary function of a four-column hydraulic press? Master Magnesium Alloy Green Body Fabrication

- Why is a pre-pressing step using a laboratory hydraulic press necessary? Key to Stable Particleboard Mats

- Is a hydraulic press better than an electric press? Choose the Right Tool for Maximum Force or Precision