At their core, mechanical presses are classified by their frame design and the mechanism used to drive the ram. The most common frame types include C-frame (or gap frame) presses, which offer easy side access, and straight-side presses, which provide maximum rigidity for high-precision work. The drive mechanism typically involves a motor, a flywheel to store energy, and a clutch/brake system to engage the ram.

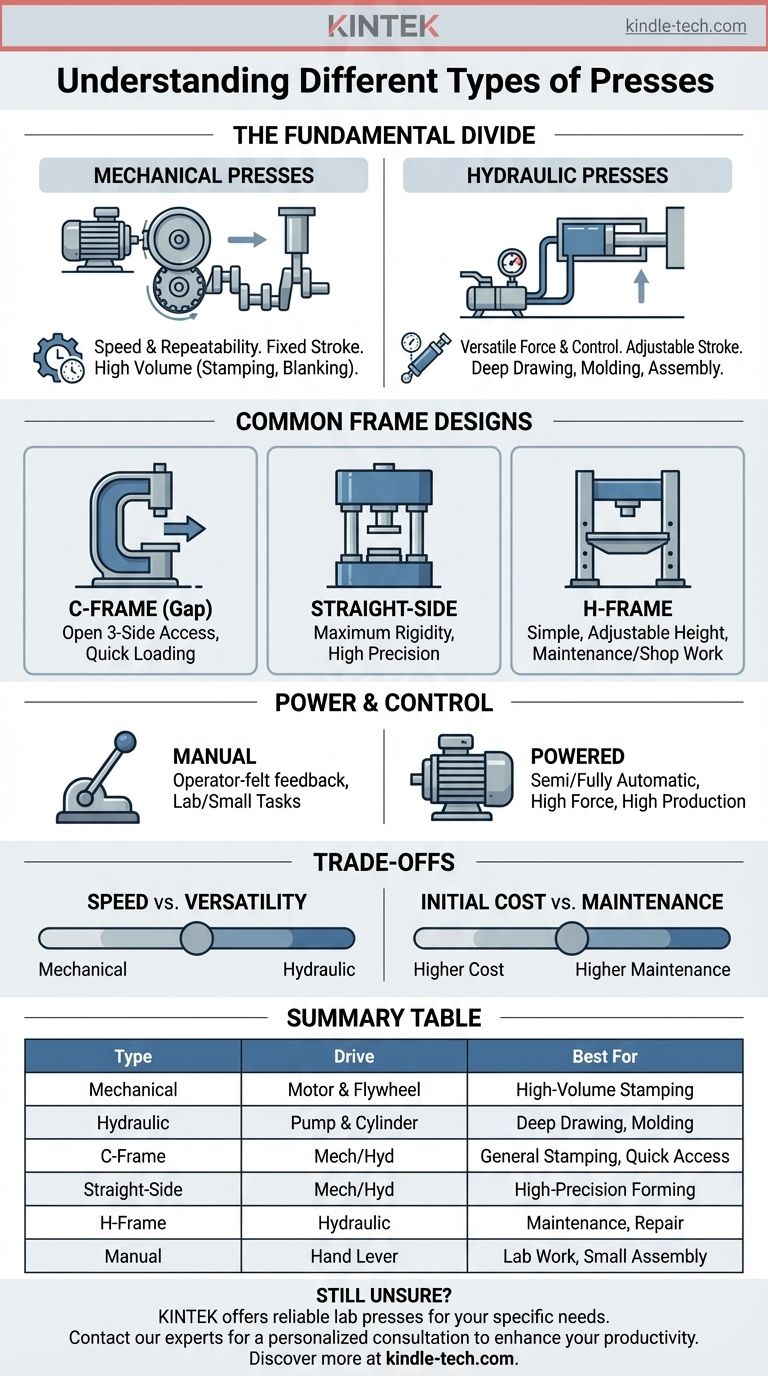

The most critical distinction to understand is not between minor variations, but the fundamental difference between mechanical and hydraulic presses. Your choice depends entirely on whether your application requires high speed and repeatability (mechanical) or variable force and control (hydraulic).

The Fundamental Divide: Mechanical vs. Hydraulic

Before detailing specific types, it's essential to clarify the primary press categories. The references frequently mention hydraulic presses, which operate on a different principle than mechanical ones.

Mechanical Presses

A mechanical press uses a motor to spin a large, heavy flywheel. When activated, a clutch connects this spinning flywheel to a crankshaft or eccentric gear, which drives a ram up and down.

Their operation is defined by a fixed stroke length. They are extremely fast and deliver precise, repeatable force at the very bottom of the stroke, making them ideal for high-volume blanking, coining, and shallow drawing operations.

Hydraulic Presses

A hydraulic press uses a motor-driven pump to move hydraulic fluid into a cylinder, applying pressure to a piston that moves the ram.

This design allows the full pressing force to be applied at any point in the stroke, not just the bottom. They are highly controllable and versatile but generally slower than their mechanical counterparts, suiting them for deep drawing, molding, and assembly tasks.

Common Press Designs by Frame

The frame is the main structure of the press and dictates its rigidity and accessibility. This classification applies to both mechanical and hydraulic systems.

C-Frame (or Gap Frame) Presses

The frame of this press is shaped like the letter "C," providing open access on three sides.

This design is excellent for applications where operators need to load and unload parts quickly from the front or sides. It is commonly used for smaller tonnage assembly and general-purpose stamping.

Straight-Side Presses

These presses have a more robust, box-like frame with vertical columns. This design minimizes deflection under load.

The superior rigidity makes straight-side presses the standard for high-precision stamping and heavy-duty forming operations where die alignment is critical.

H-Frame Presses

Often associated with hydraulic shop presses, the H-frame is a simple and effective design for repair and maintenance work. It consists of two vertical uprights and a crossbeam, offering adjustable working heights.

How a Press is Powered and Controlled

Regardless of the frame or drive type, presses can be differentiated by their method of operation.

Manual Presses

Manual presses are operated by hand, typically with a long lever or a hand pump. They are used for low-tonnage applications like sample preparation in a lab, small assembly tasks, or repair work where precise, operator-felt feedback is valuable.

Powered Presses

Powered presses use an electric motor or other power source to drive the system, enabling much higher forces and automated cycling. These can be further subdivided:

- Semi-Automatic: The operator may initiate the cycle, but the press opens automatically after a set time or pressure.

- Fully Automatic: These are often microprocessor-controlled and can be programmed for specific forces, speeds, and dwell times, making them suitable for high-production manufacturing lines.

Understanding the Trade-offs

Choosing the right type of press requires understanding the inherent advantages and disadvantages of each primary system.

Speed vs. Versatility

A mechanical press is built for speed. Its fixed stroke allows for extremely high cycle rates (strokes per minute), perfect for mass production. However, it only delivers maximum force at the very bottom of its stroke.

A hydraulic press is far more versatile. It can deliver its full rated force at any point, and the stroke length, speed, and pressure are all adjustable. This flexibility comes at the cost of cycle speed.

Initial Cost vs. Maintenance

Mechanical presses often have a higher initial cost due to the complexity of the flywheel, clutch, and brake systems. However, they are generally reliable with routine maintenance.

Hydraulic presses can be simpler and less expensive initially, but their hydraulic systems (pumps, seals, hoses, and fluid) require consistent monitoring and maintenance to prevent leaks and ensure consistent performance.

Making the Right Choice for Your Goal

Your application's specific needs for speed, force, and control will determine the ideal press.

- If your primary focus is high-volume stamping or blanking: A mechanical press is the clear choice for its speed and repeatability.

- If your primary focus is deep drawing or complex forming: A hydraulic press provides the necessary constant force and control throughout the entire stroke.

- If your primary focus is lab work or small-scale assembly: A manual benchtop press, either mechanical (arbor) or hydraulic, offers the control and low cost you need.

- If your primary focus is maintenance and repair: A manually operated H-frame hydraulic shop press offers the best combination of force and versatility.

Ultimately, understanding the core operational differences between press systems empowers you to select the right tool for the job.

Summary Table:

| Press Type | Primary Drive Mechanism | Key Characteristics | Best For |

|---|---|---|---|

| Mechanical Press | Motor & Flywheel | High speed, fixed stroke, repeatable force | High-volume stamping, blanking |

| Hydraulic Press | Hydraulic Pump & Cylinder | Full force at any stroke point, adjustable, versatile | Deep drawing, molding, assembly |

| C-Frame Press | Mechanical or Hydraulic | Open 3-side access, good for smaller tonnage | Quick part loading/unloading, general stamping |

| Straight-Side Press | Mechanical or Hydraulic | Maximum rigidity, minimal deflection | High-precision, heavy-duty forming |

| H-Frame Press | Typically Hydraulic | Simple design, adjustable height | Maintenance, repair, shop work |

| Manual Press | Hand-operated lever/pump | Operator feedback, low cost, precise control | Lab work, small assembly, samples |

| Powered Press | Electric Motor | High force, programmable, automated cycling | High-production manufacturing |

Still Unsure Which Press is Right for Your Lab?

Selecting the correct press is critical for the efficiency and quality of your work. KINTEK specializes in lab equipment and consumables, providing reliable mechanical and hydraulic presses tailored to your specific laboratory needs—from high-volume sample preparation to precise, controlled forming tasks.

Let our experts help you find the perfect solution. We can guide you through the trade-offs between speed, force, and control to ensure you get the right press for your application and budget.

Contact KINTEL today for a personalized consultation and discover how our lab presses can enhance your productivity and results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Lab Heat Press

People Also Ask

- How does a laboratory hydraulic press contribute to the preparation of green pellets for nanostructured eutectic steel?

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation

- What is the purpose of a laboratory hydraulic press for LATP electrolyte pellets? Achieve Optimal Density & Conductivity