Choosing the right powder mixer is fundamental to ensuring product quality and process efficiency. The three most common types are tumble blenders, ribbon blenders, and vertical blenders, each operating on a distinct mechanical principle suited for different materials and outcomes. While tumble blenders gently fold materials, ribbon and vertical blenders use agitators for a more forced, convective style of mixing.

The optimal mixer is not the most powerful or complex one, but the one whose mixing mechanism—gentle diffusion versus active convection—best matches your powder's specific characteristics and your process goals for speed, integrity, and homogeneity.

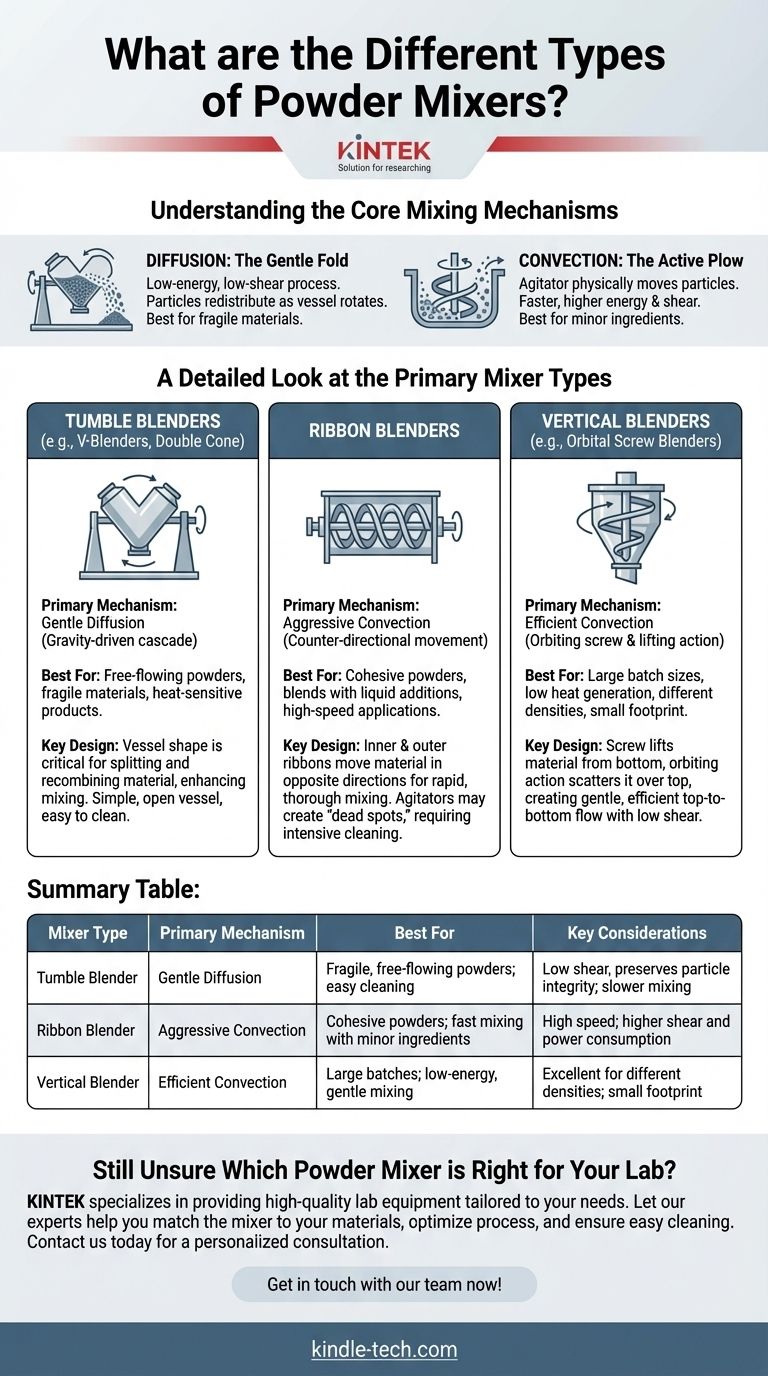

Understanding the Core Mixing Mechanisms

To select the right equipment, you must first understand the physical forces they use to blend powders. Each mechanism has a direct impact on mixing time, energy consumption, and the final state of your product.

Diffusion: The Gentle Fold

This is the primary mechanism in tumble blenders. The vessel rotates, causing the powder bed to cascade. Particles are redistributed as they roll, slide, and fall over one another in a low-energy, low-shear process.

This method is exceptionally gentle, making it ideal for blending materials that are friable, fragile, or abrasive.

Convection: The Active Plow

This mechanism uses an agitator, such as a ribbon or a screw, to physically move large groups of particles from one location to another. This is the dominant action in ribbon blenders and vertical blenders.

Convective mixing is significantly faster than diffusion and is highly effective at incorporating minor ingredients into a large batch. However, it imparts more energy and shear into the material.

A Detailed Look at the Primary Mixer Types

While all three types achieve a blend, their designs make them suitable for very different applications.

Tumble Blenders (e.g., V-Blenders, Double Cone)

Tumble blenders mix by rotating a vessel, relying on gravity to cascade the material. Their simple design lacks any internal moving parts in the product zone.

Best For: Free-flowing powders of similar particle size and density, and fragile or heat-sensitive materials that cannot tolerate high shear.

Key Design: The shape of the vessel (like the 'V' in a V-blender) is critical for splitting and recombining the material stream, which enhances the diffusive mixing effect.

Ribbon Blenders

A ribbon blender consists of a stationary U-shaped trough with a horizontal, rotating agitator. This agitator features inner and outer helical ribbons that move material in opposite axial directions.

Best For: Cohesive powders, blends with minor liquid additions, and applications where speed is a priority. The counter-directional movement provides thorough, rapid mixing.

Key Design: The outer ribbon moves material from the ends toward the center, while the inner ribbon moves it from the center out to the ends, ensuring a constant and aggressive exchange.

Vertical Blenders (e.g., Orbital Screw Blenders)

These mixers use a screw-shaped agitator that rotates on its own axis while simultaneously orbiting the wall of a conical vessel. This action lifts material from the bottom of the vessel and scatters it over the top surface.

Best For: Large batch sizes, applications requiring low heat generation, and blending materials with different densities where segregation can be an issue.

Key Design: The combination of the screw's lifting action and its orbital movement creates a gentle but highly efficient top-to-bottom convective flow with very low shear.

Understanding the Trade-offs

Choosing a mixer involves balancing competing factors. What you gain in one area, you often sacrifice in another.

Speed vs. Particle Integrity

Ribbon blenders offer rapid mixing times but their aggressive, convective action can generate heat and break down friable particles. Tumble blenders are much slower but preserve the material's original particle size and shape.

Cleaning and Batch Changeover

Tumble blenders, with their simple, open vessel design, are extremely easy to clean thoroughly. Ribbon blenders have agitators, shafts, and seals that create "dead spots" and require more intensive cleaning protocols between batches.

Power Consumption and Footprint

Ribbon blenders are generally more power-intensive due to the force required to drive material with the agitator. Vertical blenders can handle very large volumes with a relatively small floor footprint, while horizontal ribbon and tumble blenders require more space.

Incorporating Minor Ingredients

The active, forced movement of convective mixers (Ribbon and Vertical) is superior for quickly and evenly dispersing very small amounts of a key ingredient throughout a large volume of powder.

Making the Right Choice for Your Powder

Your final decision should be driven by a clear understanding of your primary objective.

- If your primary focus is preserving fragile crystals or coated particles: A Tumble Blender is the ideal choice for its gentle, low-shear action.

- If your primary focus is speed and dispersing minor liquids or solids: A Ribbon Blender provides the aggressive, convective action needed for rapid, homogeneous results.

- If your primary focus is large-volume, low-energy mixing: A Vertical Blender offers an efficient balance of capacity, gentle handling, and a small footprint.

- If your primary focus is frequent product changeovers and sanitation: The simple, accessible design of a Tumble Blender makes it the easiest to clean.

By aligning the mixer's mechanical action with your material's properties, you ensure an efficient process and a high-quality final product.

Summary Table:

| Mixer Type | Primary Mechanism | Best For | Key Considerations |

|---|---|---|---|

| Tumble Blender | Gentle Diffusion | Fragile, free-flowing powders; easy cleaning | Low shear, preserves particle integrity; slower mixing |

| Ribbon Blender | Aggressive Convection | Cohesive powders; fast mixing with minor ingredients | High speed; higher shear and power consumption |

| Vertical Blender | Efficient Convection | Large batches; low-energy, gentle mixing | Excellent for different densities; small footprint |

Still Unsure Which Powder Mixer is Right for Your Lab?

Selecting the ideal powder mixer is critical for achieving consistent results and maintaining the integrity of your materials. KINTEK specializes in providing high-quality lab equipment, including powder mixers tailored to your specific application needs.

Let our experts help you:

- Match the mixer to your materials – whether you're working with fragile crystals, cohesive powders, or large-volume batches.

- Optimize your process for speed, efficiency, and product quality.

- Ensure easy cleaning and changeover with equipment designed for your workflow.

Contact us today for a personalized consultation and discover how the right powder mixer can enhance your laboratory's productivity and results. Get in touch with our team now!

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Benchtop Laboratory Vacuum Freeze Dryer

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

People Also Ask

- What is a laboratory mixer? A Guide to Achieving Perfect Sample Homogeneity

- How does a constant temperature rotary shaker contribute to evaluating iron nanoparticles? Optimize Dye Degradation

- What is grinder in chemistry? A Guide to Precision Sample Preparation

- What are laboratory mixers used for? Achieve Perfect Sample Homogeneity and Reliable Results

- What is the function of high-shear dispersion equipment in corona-resistant nanocomposites? Elevate Your Insulation