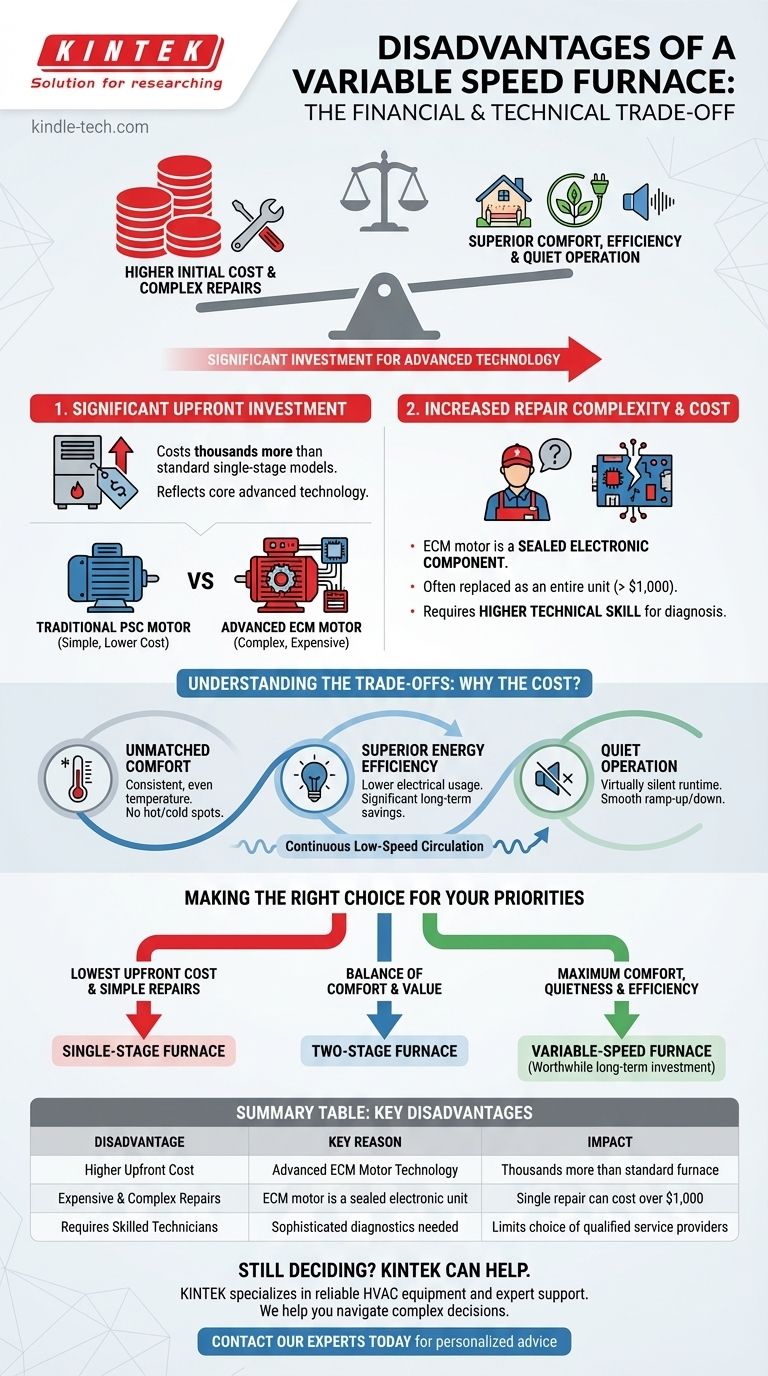

The primary drawbacks of a variable speed furnace are its higher initial cost and the increased complexity and expense of its repairs. While they offer superior comfort and efficiency, these benefits come with a significant financial and technical trade-off compared to simpler, single-stage models. The decision to invest in one hinges on understanding this fundamental balance.

A variable speed furnace is not inherently better or worse; it's a more advanced piece of technology. Its disadvantages are centered on the higher cost of acquiring and maintaining that technology, a trade-off for achieving a new level of home comfort and energy efficiency.

The Core Disadvantages Explained

The downsides of a variable speed furnace can be traced directly to the advanced components that give it its name—specifically, the sophisticated motor and control board.

The Significant Upfront Investment

A new variable speed furnace can cost thousands more than a standard single-stage model. This price difference is not arbitrary; it reflects the cost of its core technology.

The system is built around an Electronically Commutated Motor (ECM), which is fundamentally more complex and expensive to manufacture than the simple Permanent Split Capacitor (PSC) motor found in traditional furnaces.

Increased Repair Complexity and Cost

When a standard PSC motor fails, a technician can often replace it for a few hundred dollars. The repair is relatively straightforward.

The ECM motor, by contrast, is a sealed electronic component. If it fails, it is almost always replaced as an entire unit, not repaired. This single component can cost well over a thousand dollars to replace, significantly increasing the financial risk of an out-of-warranty failure.

Furthermore, diagnosing issues with these more complex systems requires a higher level of technical skill, potentially limiting your choice of qualified service technicians.

Understanding the Trade-offs: Cost vs. Performance

The disadvantages do not exist in a vacuum. They are the direct trade-offs for the unique benefits that a variable speed furnace provides. Understanding this balance is key to making an informed decision.

The Technology at Work: The ECM Motor

Think of a standard furnace motor like a light switch: it's either fully on or fully off. It blasts air at high speed until the thermostat is satisfied, then shuts down completely.

An ECM motor operates more like a dimmer switch. It can adjust its speed precisely, often running for long periods at a very low, quiet, and energy-efficient level. This continuous circulation is the source of its primary benefits.

Benefit 1: Unmatched Comfort

By constantly circulating air at a low speed, a variable speed furnace eliminates the hot and cold spots common with standard models. It provides a far more consistent and even temperature throughout your home. This slow, steady airflow also improves humidity control in both winter and summer.

Benefit 2: Superior Energy Efficiency

The ECM motor itself uses significantly less electricity than a traditional PSC motor. While the furnace's gas consumption might be similar to a two-stage model, the electrical savings from the blower fan can be substantial over the life of the unit, helping to offset the initial cost.

Benefit 3: Quiet Operation

The abrupt roar of a standard furnace kicking on is absent. Instead, a variable speed furnace "ramps up" and "ramps down" slowly. For most of its runtime, it operates at such a low level that it is often virtually silent.

Making the Right Choice for Your Home

The correct furnace is the one that best aligns with your budget, climate, and personal priorities for comfort and efficiency.

- If your primary focus is the lowest possible upfront cost and simple repairs: A traditional single-stage furnace is the most straightforward and budget-friendly choice.

- If your primary focus is a balance of improved comfort and value: A two-stage furnace, which has high and low settings, offers a good compromise between the simplicity of single-stage and the performance of variable-speed.

- If your primary focus is maximum comfort, quietness, and long-term efficiency: The higher initial cost and potential repair expense of a variable-speed furnace are a worthwhile investment for the superior living environment it creates.

Understanding these key distinctions empowers you to choose a system based on your long-term priorities, not just the initial price tag.

Summary Table:

| Disadvantage | Key Reason | Impact |

|---|---|---|

| Higher Upfront Cost | Advanced ECM motor technology | Thousands more than a standard furnace |

| Expensive & Complex Repairs | ECM motor is a sealed electronic unit | Single repair can cost over $1,000 |

| Requires Skilled Technicians | Sophisticated diagnostics needed | Limits choice of qualified service providers |

Still deciding on the right furnace for your needs?

The choice between a standard, two-stage, or variable speed furnace depends on your specific priorities for comfort, efficiency, and budget. The advanced technology in variable speed models offers superior performance but comes with specific trade-offs.

KINTEK specializes in providing reliable equipment and expert support for all your HVAC and laboratory needs. Whether you're a homeowner or a facilities manager, we can help you navigate these complex decisions.

Contact our experts today for personalized advice and to find the perfect solution for your home or facility.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor