At its core, an induction heating system design is an electro-thermal puzzle. The primary elements are a high-frequency power supply, a precisely shaped induction coil, and the workpiece to be heated, all working in concert. The design process involves selecting the right power, frequency, and coil geometry to generate heat electromagnetically, exactly where and when you need it.

The success of any induction heating design hinges on one principle: matching the system's electrical characteristics to the material properties of the workpiece and the desired heating outcome. It's a careful balance of frequency, power, and coil geometry to control the depth, rate, and location of the heat.

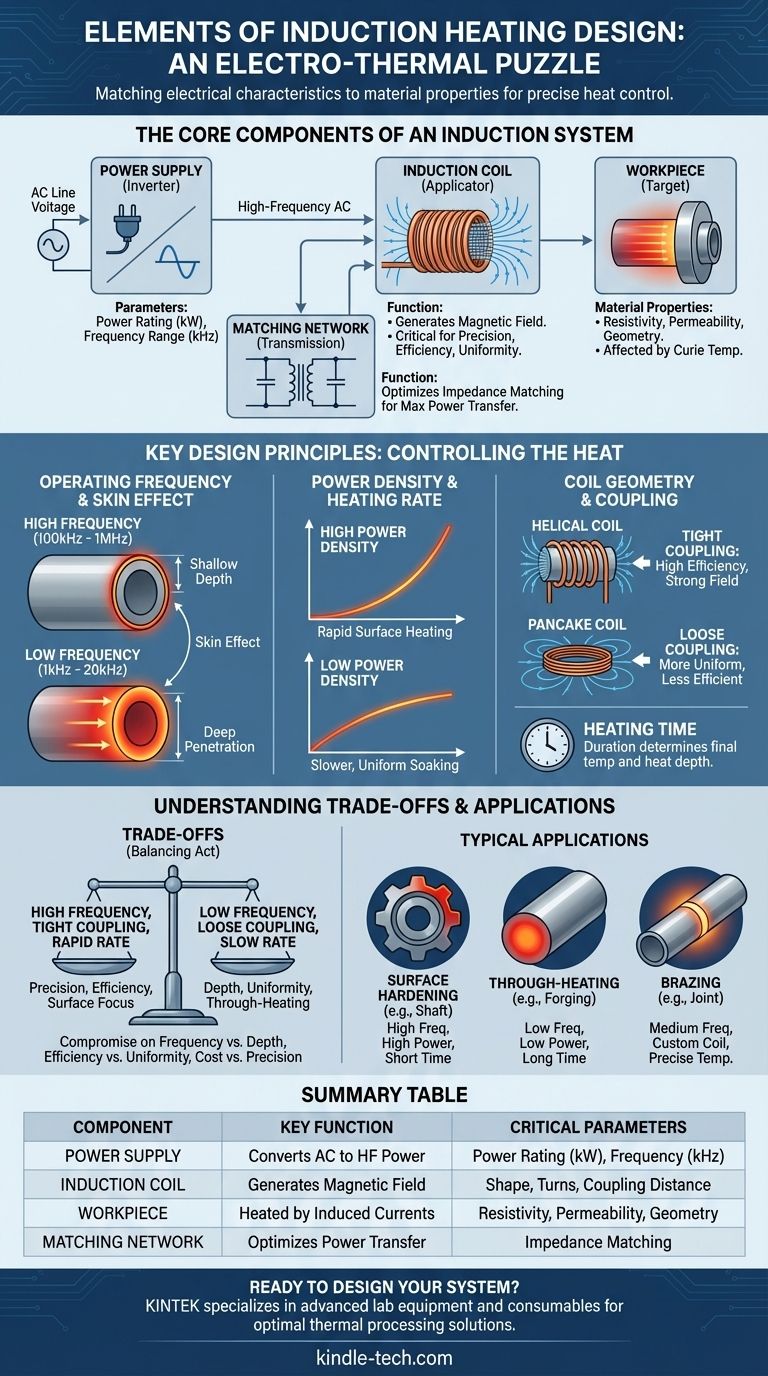

The Core Components of an Induction System

An induction heating setup is an integrated system. Understanding how each component contributes is the first step in a successful design.

The Power Supply: The Engine

The power supply, or inverter, is the heart of the system. It converts standard AC line voltage into high-frequency AC electricity.

The two most critical parameters of the power supply are its power rating (kW) and its frequency range (kHz). The power rating dictates how much energy can be delivered, which influences the maximum heating rate.

The Induction Coil: The Applicator

The induction coil (or inductor) is a custom-shaped copper conductor, typically water-cooled, that generates the alternating magnetic field. This field is what induces the heating current in the workpiece.

Coil design is arguably the most critical element for precision. Its shape, number of turns, and proximity to the part determine the efficiency and uniformity of the heating pattern.

The Workpiece: The Target

The workpiece itself is an active electrical component in the circuit. Its material properties—resistivity, magnetic permeability, and geometry—dictate how it will respond to the magnetic field.

For example, magnetic steels are much easier to heat below their Curie temperature (around 770°C or 1420°F) than non-magnetic materials like aluminum or copper.

The Matching Network: The Transmission

Often housed with the power supply or in a separate "heat station," a matching network of capacitors and transformers fine-tunes the system.

Its job is to match the electrical impedance of the coil and workpiece to the ideal operating point of the power supply. A well-matched system ensures maximum power is transferred to the part instead of being wasted as heat in the components.

Key Design Principles: Controlling the Heat

The components are just the tools. The real design work lies in applying core physics principles to achieve a specific thermal outcome, such as surface hardening, melting, or brazing.

Operating Frequency: Defining the "Skin Effect"

The single most important design choice is the operating frequency. High-frequency currents tend to flow only on the surface of a conductor, a phenomenon known as the skin effect.

A higher frequency results in a shallower heating depth (reference depth). A lower frequency allows the induced currents to penetrate deeper into the material.

- High Frequency (100 kHz - 1 MHz): Ideal for surface hardening, brazing thin materials, or heating very small parts.

- Low Frequency (1 kHz - 20 kHz): Used for through-heating large billets, forging, or deep case hardening.

Power Density: Setting the Heating Rate

Power density is the amount of power applied per unit of surface area (e.g., Watts per cm²). It directly controls how quickly the surface of the workpiece heats up.

High power density provides rapid heating, which is essential for surface treatments where you want to heat the surface before the core gets hot. Lower power density results in slower, more gentle heating, allowing heat to soak evenly through the part.

Coil Geometry and Coupling: Focusing the Energy

The coupling distance—the gap between the coil and the workpiece—is critical. Tighter coupling (a smaller gap) results in more efficient energy transfer and a stronger magnetic field.

The coil's shape must also mirror the part's geometry to ensure uniform heating. A cylindrical part uses a helical (solenoid) coil, while a flat surface might use a "pancake" coil.

Heating Time: Achieving the Target Temperature

Finally, the heating time is the duration for which power is applied. This, combined with power density, determines the final temperature and the depth to which heat conducts from the surface into the core of the part.

Understanding the Trade-offs

Every induction design involves balancing competing factors. Being aware of these trade-offs is the mark of an experienced designer.

Frequency vs. Heating Depth

This is the fundamental compromise. You cannot achieve deep, through-heating with a very high frequency, and you cannot achieve precise, shallow surface hardening with a very low frequency. The frequency must be chosen to match the target heating depth for the specific material.

Efficiency vs. Uniformity

Tightly coupling the coil to the part is highly efficient, transferring the maximum amount of energy. However, it can create hot spots and non-uniform heating, especially around sharp corners.

Loosening the coupling provides a more uniform heating pattern but reduces energy efficiency, requiring more power or a longer heating time to achieve the same result.

Cost vs. Precision

A simple, single-turn coil and a basic power supply may be inexpensive. However, achieving a complex heating pattern on an intricate part may require a sophisticated, multi-axis scanning system, a CNC-machined coil, and an advanced power supply, significantly increasing cost.

Making the Right Choice for Your Goal

Your application dictates the design. There is no single "best" setup; there is only the best setup for your specific thermal processing goal.

- If your primary focus is surface hardening a steel shaft: You will use a high frequency, a high power density, and a very short heating time to heat the outer skin rapidly before quenching.

- If your primary focus is through-heating a large aluminum billet for forging: You will use a low frequency and a longer heating time to allow the heat to penetrate and soak evenly throughout the entire part.

- If your primary focus is brazing a copper-to-steel joint: You will use a medium-to-high frequency and a custom-shaped coil designed to heat the joint area to the braze alloy's melting point without overheating the surrounding components.

By mastering these core elements, you can engineer an induction process that is not only fast and efficient but also precisely tailored to your manufacturing needs.

Summary Table:

| Component | Key Function | Critical Parameters |

|---|---|---|

| Power Supply | Converts AC to high-frequency power | Power rating (kW), Frequency (kHz) |

| Induction Coil | Generates magnetic field for heating | Shape, turns, coupling distance |

| Workpiece | Material heated by induced currents | Resistivity, permeability, geometry |

| Matching Network | Optimizes power transfer efficiency | Impedance matching |

Ready to design a precise and efficient induction heating system for your lab or production line? KINTEK specializes in advanced lab equipment and consumables, offering tailored solutions for your thermal processing challenges. Whether you need surface hardening, brazing, or through-heating, our expertise ensures optimal performance and reliability. Contact us today to discuss how we can enhance your manufacturing process!

Visual Guide

Related Products

- Infrared Heating Quantitative Flat Plate Press Mold

- 30L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- Do I need a heat press machine? Unlock Professional, Durable Custom Apparel

- How long does a heat press machine last? Maximize Your Investment with the Right Choice

- What's the difference between a heat press machine and an iron? Achieve Professional, Durable Apparel Transfers

- What are the primary functions of graphite molds in hot-pressing sintering? Achieve Precision in Silicon Nitride Ceramic