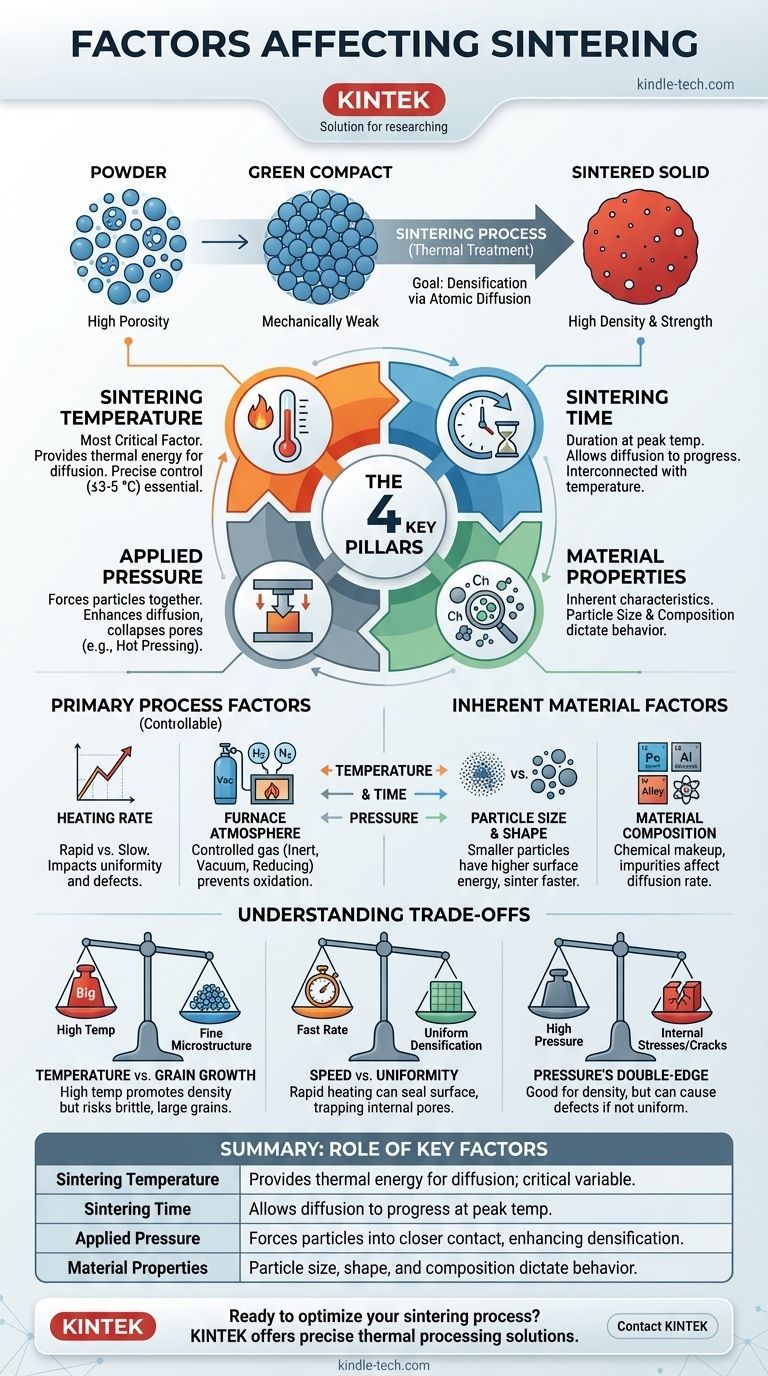

At its core, the sintering process is governed by four key elements. These are the sintering temperature, the time held at that temperature, the applied pressure, and the inherent characteristics of the material itself, including particle size and composition. These factors work in concert to control the atomic diffusion that fuses a powder into a dense, solid mass.

Sintering is not merely a heating process; it is the precise manipulation of energy and material properties to control atomic movement. The ultimate goal is to eliminate the empty spaces (porosity) between initial particles, and each factor serves as a critical lever to achieve the desired density and strength in the final product.

The Core Sintering Mechanism

Before examining the factors, it's essential to understand the fundamental goal of the process.

What is Sintering?

Sintering is a thermal treatment that transforms a collection of powder particles into a solid, coherent object. This is achieved by applying heat at a temperature below the material's melting point.

Instead of melting, atoms at the contact points between particles diffuse across the boundaries. This atomic migration gradually fills the voids between particles, fusing them together.

The Goal: From Powder to Solid

The primary objective is densification. The process starts with a pressed "green compact," which is porous and mechanically weak. Sintering aims to eliminate this porosity, causing the part to shrink and its density to increase, dramatically improving its strength and other material properties.

The Primary Process Factors

These are the variables you can directly control during the manufacturing cycle. They are the most powerful tools for influencing the final outcome.

Sintering Temperature

This is arguably the most critical factor. Temperature provides the thermal energy required to drive atomic diffusion. Higher temperatures accelerate this process significantly.

However, control must be exceptionally precise. As noted in manufacturing guidelines, the temperature often cannot deviate by more than ±3-5 °C, as even small fluctuations can drastically alter the final properties.

Sintering Time

Time is the second half of the energy equation. It refers to the duration the material is held at the peak sintering temperature.

Longer times allow the diffusion process to progress further, leading to greater densification and pore elimination. Temperature and time are deeply interconnected; a slightly lower temperature might achieve the same result as a higher one if the hold time is extended.

Applied Pressure

Pressure physically forces particles into closer contact, which enhances the diffusion process and helps collapse pores. It is applied during the initial pressing of the "green compact" and sometimes during the heating cycle itself in processes like hot pressing.

This mechanical assistance can significantly speed up densification and allow for the use of lower sintering temperatures.

Heating Rate

The rate at which the material is heated to the sintering temperature is also a key variable. A rapid heating rate can sometimes be beneficial, but it also risks trapping gases within the material or creating thermal stresses.

A controlled, slower heating rate allows for more uniform densification and helps prevent internal defects.

Furnace Atmosphere

The composition of the gas inside the sintering furnace is crucial. A controlled atmosphere (such as inert gas, vacuum, or a reducing gas like hydrogen) is used to prevent oxidation or other unwanted chemical reactions with the material, which could compromise its integrity.

Inherent Material Factors

These are properties of the raw powder that are determined before the sintering process begins.

Particle Size and Shape

Smaller particles possess a higher surface-area-to-volume ratio. This high surface energy provides a stronger driving force for diffusion, allowing smaller powders to sinter faster and at lower temperatures than coarser ones.

Material Composition

The chemical makeup of the powder is fundamental. The rate of atomic diffusion varies widely between different materials. Furthermore, the presence of impurities or alloying elements can either accelerate or inhibit the sintering process. A homogeneous composition is vital for uniform densification.

Understanding the Trade-offs

Optimizing sintering is a balancing act. Pushing one factor to its extreme often creates negative consequences elsewhere.

Temperature vs. Grain Growth

While high temperatures promote density, they also encourage grain growth. If grains become too large, the material can become brittle, even if it is fully dense. The ideal process achieves high density while maintaining a fine, controlled grain structure.

Speed vs. Uniformity

Using a very high heating rate to shorten cycle times can be efficient, but it can also cause the surface of the part to densify and seal off before internal pores have escaped. This can lead to a dense outer shell with a porous, weaker interior.

Pressure's Double-Edged Sword

High pressure is excellent for densification but can also introduce internal stresses or cause cracking if not applied uniformly. The design of the mold and die used to create the green compact is critical to managing this.

Optimizing Sintering for Your Goal

The "best" parameters are entirely dependent on the desired outcome for the final component.

- If your primary focus is maximum density and strength: Prioritize smaller particle sizes and higher temperatures, but carefully manage the hold time to prevent excessive grain growth.

- If your primary focus is preserving a fine microstructure for specific properties (e.g., magnetic, optical): Consider using lower temperatures for longer times or exploring advanced methods like Spark Plasma Sintering (SPS) that use rapid heating to limit grain growth.

- If your primary focus is cost-effective, high-volume production: The goal is to find the optimal balance between temperature and time to minimize energy consumption and cycle time while still meeting the minimum required performance specifications.

Ultimately, mastering sintering comes from understanding that these factors form an interconnected system that must be precisely balanced to engineer the final material.

Summary Table:

| Factor | Role in Sintering Process |

|---|---|

| Sintering Temperature | Provides thermal energy for atomic diffusion; most critical variable. |

| Sintering Time | Duration at peak temperature; allows diffusion process to progress. |

| Applied Pressure | Forces particles into closer contact, enhancing densification. |

| Material Properties | Particle size, shape, and composition dictate sintering behavior. |

Ready to optimize your sintering process for superior material performance? The precise control of temperature, time, and atmosphere is critical to achieving the density, strength, and microstructure you require. KINTEK specializes in high-performance lab furnaces and sintering equipment, offering the precise thermal processing solutions your laboratory needs. Let our experts help you select the right equipment to master these key variables. Contact KINTEK today to discuss your specific application and goals!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites

- How does the uniaxial pressing function of a vacuum hot press furnace influence the microstructure of ZrC-SiC ceramics?

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production