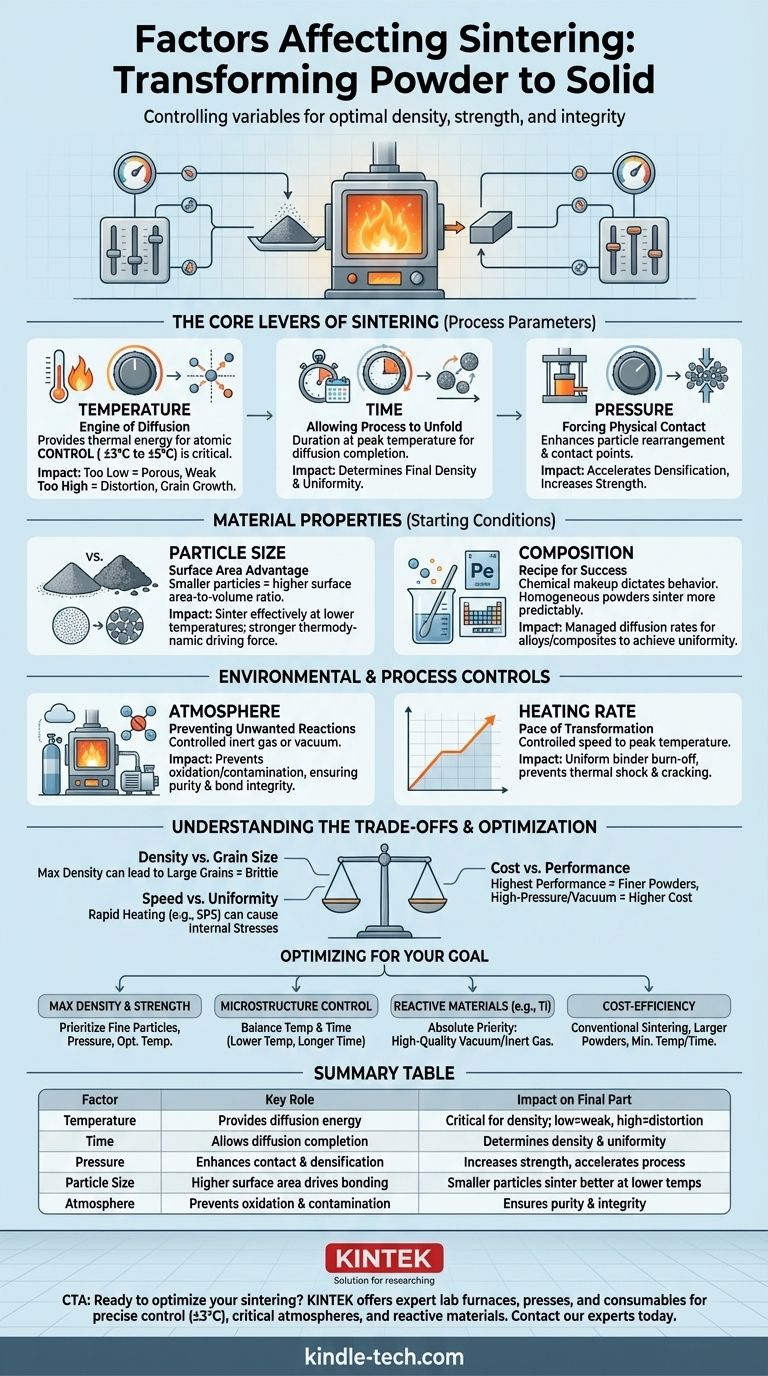

The quality of a sintered part is not accidental; it is a direct result of carefully controlling several key process variables. The most critical factors affecting sintering are temperature, time, external pressure, and the intrinsic properties of the powder itself, such as particle size and composition. The atmospheric conditions during the process are also a crucial determining factor.

Sintering is fundamentally a process of atomic diffusion, transforming a powder into a dense solid. Each influencing factor acts as a lever to control the rate and extent of this transformation, directly impacting the final product's strength, density, and structural integrity.

The Core Levers of Sintering

Sintering is driven by thermal energy and physical contact. The primary process parameters are the knobs you turn to control the outcome.

Temperature: The Engine of Diffusion

Temperature is the single most important factor in sintering. It provides the thermal energy required for atoms to migrate across the boundaries of individual particles, fusing them together.

The temperature requirements are extremely strict. In many industrial processes, the furnace temperature cannot deviate by more than ±3°C to ±5°C from the target.

Too little heat results in an incomplete bond, leaving a porous and weak part. Too much heat can cause unwanted grain growth, melting, or distortion of the component.

Time: Allowing the Process to Unfold

Sintering is not an instantaneous event. A specific duration at the peak temperature, known as sintering time or "soak time," is necessary to allow the diffusion process to complete.

This duration gives atoms enough time to travel and fill the voids between particles, which is how the part achieves its final density.

Pressure: Forcing Physical Contact

Pressure plays a critical role by enhancing particle rearrangement and improving the points of contact where diffusion occurs.

This is often applied during an initial compaction phase, where a hydraulic press shapes the powder in a mold and die. The result is a fragile "green" piece that has enough integrity to be moved to the sintering furnace. Applying pressure during sintering itself (as in hot pressing) can dramatically accelerate densification.

Material Properties: The Starting Conditions

The raw material's characteristics establish the foundation for the entire process. You cannot achieve a high-quality output from a poorly specified input.

Particle Size: The Surface Area Advantage

Smaller particles sinter more effectively and at lower temperatures. This is because they have a much higher surface-area-to-volume ratio.

This high surface area creates a powerful thermodynamic driving force for the particles to bond together, as it reduces the total surface energy of the system.

Composition: The Recipe for Success

The chemical makeup of the powder dictates its sintering behavior. A homogeneous, pure powder will sinter more predictably than a mixed or contaminated one.

When creating alloys or composites, the different sintering temperatures and diffusion rates of each constituent material must be carefully managed to achieve a uniform final product.

Environmental & Process Controls

The environment in which sintering occurs can either enable or inhibit the process.

Atmosphere: Preventing Unwanted Reactions

The composition of the gas inside the furnace is critical, especially for metals. Sintering is often performed in a vacuum or an inert gas atmosphere (like argon).

This controlled atmosphere prevents oxidation and other chemical reactions that would interfere with the atomic bonding between particles, ensuring the purity and integrity of the final material.

Heating Rate: The Pace of Transformation

The speed at which the material is brought to its peak sintering temperature can influence the final density and microstructure.

A controlled heating rate allows for the uniform burn-off of any binders used during the initial pressing stage and helps prevent thermal shock, which could crack the part before it is fully densified.

Understanding the Trade-offs

Optimizing the sintering process always involves balancing competing factors. Understanding these trade-offs is key to achieving a successful outcome.

Density vs. Grain Size

Pushing for maximum density by using very high temperatures or long sintering times can lead to excessive grain growth. While the part may be dense, large grains can often make the material more brittle, reducing its toughness.

Speed vs. Uniformity

Advanced methods like Spark Plasma Sintering (SPS) can drastically reduce processing time. However, rapid heating can sometimes introduce internal stresses or result in less uniform densification compared to slower, conventional methods, especially in complex geometries.

Cost vs. Performance

Achieving the highest performance—maximum density, fine grain structure, and high purity—often requires more expensive inputs and processes. Finer powders, high-pressure equipment, and high-vacuum furnaces all increase costs significantly. The key is to match the process parameters to the application's actual performance requirements.

Optimizing Sintering for Your Goal

The ideal combination of factors depends entirely on the desired properties of the final component.

- If your primary focus is maximum density and strength: Prioritize finer particle sizes, sufficient external pressure, and optimizing temperature just below the material's melting point.

- If your primary focus is controlling microstructure (e.g., grain size): Carefully balance temperature and time; a slightly lower temperature for a longer duration can increase density while limiting grain growth.

- If your primary focus is processing reactive materials (e.g., titanium): Your absolute priority is the furnace atmosphere; a high-quality vacuum or pure inert gas environment is non-negotiable to prevent contamination.

- If your primary focus is cost-efficiency for less critical parts: Use conventional sintering with more affordable, larger powders, focusing on finding the minimum temperature and time required to meet the part's specifications.

Ultimately, mastering sintering lies in understanding how these factors interact to reliably transform a loose powder into a precisely engineered solid component.

Summary Table:

| Factor | Key Role in Sintering | Impact on Final Part |

|---|---|---|

| Temperature | Provides energy for atomic diffusion | Critical for density; too low = weak, too high = distortion |

| Time | Allows diffusion process to complete | Determines final density and uniformity |

| Pressure | Enhances particle contact and densification | Increases strength, accelerates process |

| Particle Size | Higher surface area drives bonding | Smaller particles sinter better at lower temperatures |

| Atmosphere | Prevents oxidation and contamination | Ensures material purity and integrity |

Ready to optimize your sintering process for superior results?

The factors of temperature, time, and atmosphere require precise control, which is where expert equipment makes the difference. At KINTEK, we specialize in high-performance lab furnaces, presses, and consumables designed specifically for the demanding needs of materials sintering.

We provide the reliable tools you need to:

- Achieve precise temperature control (±3°C) for consistent results

- Maintain critical vacuum or inert gas atmospheres

- Process reactive materials like titanium without contamination

Don't leave your sintering outcomes to chance. Contact our experts today to discuss how KINTEK's solutions can help you achieve denser, stronger, and more reliable sintered components.

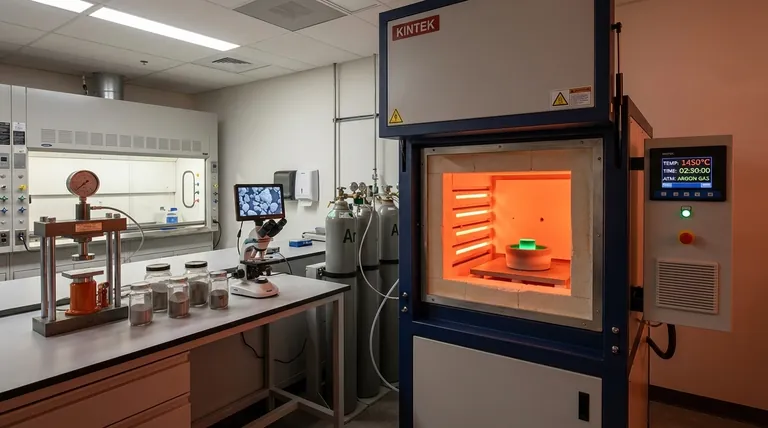

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How are high-temperature muffle or tube furnaces utilized in the hydrothermal aging of catalysts? Expert Analysis

- What is the function of a high-temperature furnace in the preparation of Rh/CeαZr1-αO2 catalysts? Optimize Stability

- Why must the Silicalite-1 seed layer undergo calcination? Unlock Superior Zeolite Film Growth Today

- What is a calcining furnace? A Guide to High-Temperature Material Transformation

- What role does a laboratory box resistance furnace play in PDC coating pyrolysis? Optimize Your Ceramic Transformation

- What is the sintered manufacturing process? A Guide to Precision & Efficiency

- What role does a high-temperature muffle furnace play in the measurement of ash content in biomass samples? Accurate Analysis Guide

- What critical experimental conditions do high-temperature muffle furnaces provide? Optimize Chlorine & Slagging Tests