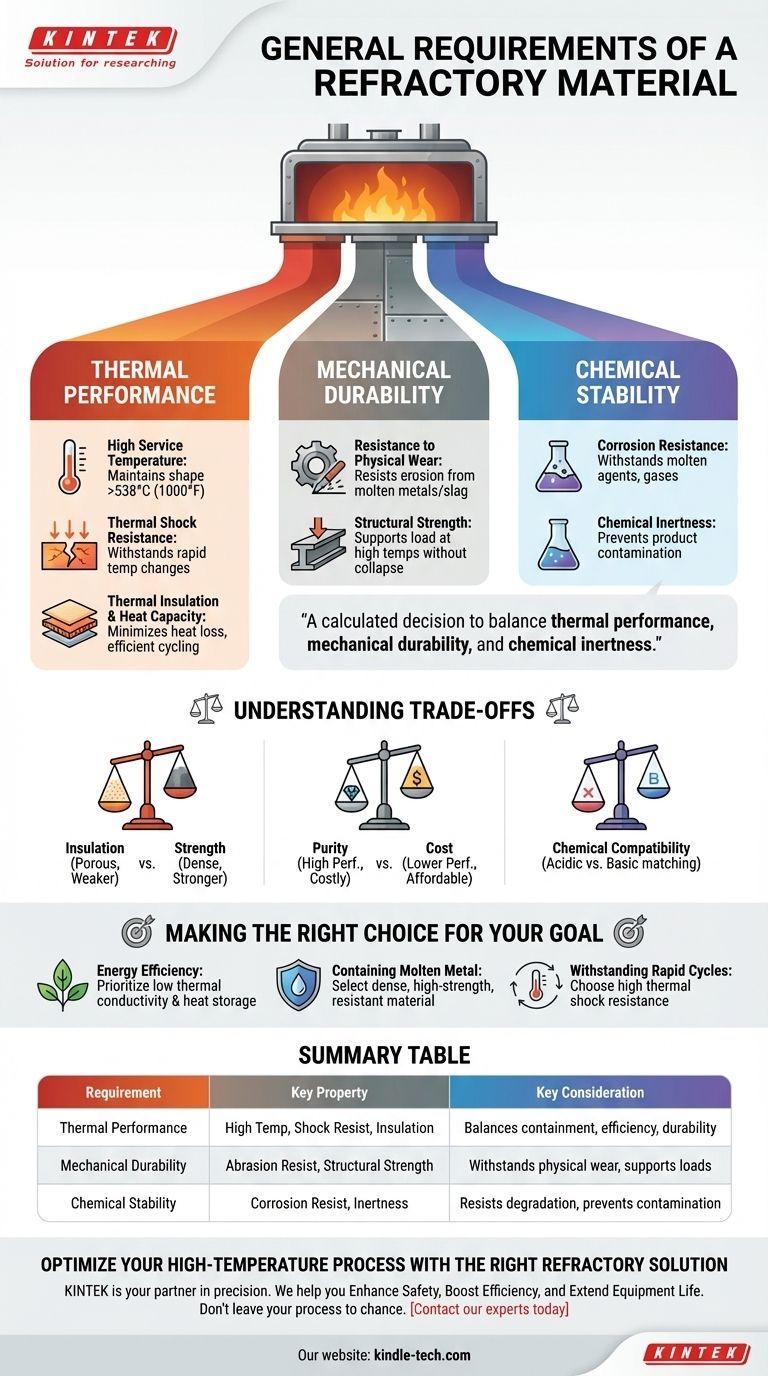

At its core, a refractory material has three fundamental requirements: it must withstand extremely high temperatures, resist physical wear and abrasion, and remain stable when exposed to corrosive chemical agents. These materials are specifically engineered to function in environments above 538°C (1000°F), where standard materials would fail.

The selection of a refractory is not merely about surviving heat. It is a calculated decision to balance thermal performance, mechanical durability, and chemical inertness to ensure the safety, efficiency, and longevity of a high-temperature industrial process.

The Primary Requirement: Thermal Performance

A refractory's most defining characteristic is its ability to perform under extreme thermal stress. This goes far beyond simply not melting.

High Service Temperature (Refractoriness)

This is the most obvious requirement. A refractory must maintain its physical shape and chemical identity at the intended operating temperature without softening, melting, or deforming under load.

Thermal Shock Resistance

Industrial processes often involve rapid temperature changes. A refractory must be able to withstand these fast heating and cooling cycles without cracking or spalling, ensuring the structural integrity of the furnace or vessel.

Thermal Insulation & Heat Capacity

Effective refractories often provide good thermal insulation, minimizing heat loss and improving energy efficiency. A low heat storage capacity is also desirable, as it allows the furnace to heat up and cool down faster, saving both time and energy.

The Mandate for Mechanical Durability

Heat is not the only force at play. A refractory must be physically tough enough to survive its operational environment.

Resistance to Physical Wear

Many high-temperature processes involve the movement of molten metals, slag, or hot gases. The refractory lining must resist the resulting physical erosion and abrasion to prevent premature failure.

Structural Strength

A refractory must have sufficient mechanical strength to support its own weight and any structural loads at high temperatures. A material that softens, even if it doesn't melt, can lead to a catastrophic collapse of the furnace lining.

The Challenge of Chemical Stability

The inside of a furnace is a highly reactive environment. A refractory must act as a stable, non-reactive barrier.

Corrosion Resistance

Refractories are constantly exposed to corrosive agents like molten slag, metals, and process gases. They must be chemically resistant to these agents to avoid being dissolved or degraded, which would compromise the lining and contaminate the product.

Chemical Inertness

A key requirement is that the refractory material does not react with the materials being processed. This prevents contamination of the final product and ensures the chemical integrity of both the refractory and the furnace contents.

Understanding the Trade-offs

No single refractory material excels in all areas. The selection process always involves balancing competing properties to fit a specific application.

Insulation vs. Strength

Highly porous materials are excellent thermal insulators but are often mechanically weaker than dense, less-porous materials. A dense brick can bear more load but will allow more heat to escape.

Purity vs. Cost

Higher-purity refractories generally offer superior high-temperature performance and corrosion resistance. However, this increased performance comes at a significantly higher cost.

Chemical Compatibility

A refractory that is highly resistant to an acidic chemical environment (like silica-based materials) may be quickly destroyed by a basic one (containing lime or magnesia), and vice versa. The refractory's chemistry must be matched to the process chemistry.

Making the Right Choice for Your Goal

Selecting the correct refractory depends entirely on the primary demand of your specific industrial process.

- If your primary focus is energy efficiency: Prioritize materials with low thermal conductivity and low heat storage capacity to minimize heat loss.

- If your primary focus is containing molten metal or abrasive solids: Select a dense, high-strength refractory with proven resistance to physical wear and chemical corrosion.

- If your primary focus is withstanding rapid temperature changes: Choose a material specifically engineered for high thermal shock resistance to prevent cracking and failure during cycling.

Understanding these foundational requirements is the first step toward optimizing the safety, efficiency, and output of any high-temperature operation.

Summary Table:

| Requirement | Key Property | Key Consideration |

|---|---|---|

| Thermal Performance | High service temperature, Thermal shock resistance, Good insulation | Balances heat containment with energy efficiency and cycling durability. |

| Mechanical Durability | Resistance to abrasion, High structural strength | Withstands physical wear from molten materials and supports structural loads. |

| Chemical Stability | Corrosion resistance, Chemical inertness | Resists degradation from slag, metals, and gases; prevents product contamination. |

Optimize Your High-Temperature Process with the Right Refractory Solution

Selecting the ideal refractory material is a critical decision that directly impacts the safety, efficiency, and longevity of your operations. The wrong choice can lead to premature failure, product contamination, and costly downtime.

KINTEK is your partner in precision. We specialize in supplying high-performance lab equipment and consumables, including refractory materials tailored to withstand extreme environments. Our experts understand the intricate balance between thermal performance, mechanical strength, and chemical compatibility.

We help you:

- Enhance Safety: Choose materials that ensure structural integrity under extreme thermal and mechanical stress.

- Boost Efficiency: Select refractories with optimal insulation properties to reduce energy consumption and operating costs.

- Extend Equipment Life: Prevent premature lining failure by matching the refractory's properties to your specific process chemistry and conditions.

Don't leave your process to chance. Whether your primary goal is energy efficiency, containing molten metal, or withstanding rapid temperature cycles, KINTEK has the expertise and products to meet your laboratory's demanding needs.

Contact our experts today for a personalized consultation and let us help you select the perfect refractory material to achieve superior performance and reliability.

Visual Guide

Related Products

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

People Also Ask

- How is a circulating water vacuum pump utilized for hydrogen production residues? Optimize Your Solid-Liquid Separation

- What core role do high-precision vacuum pumps play in PCL-TPE polycondensation? Master Molecular Growth Control

- What role does a high-purity quartz tube serve within a laboratory fluidized bed reactor system? Key Vessel Functions

- Why is a benchtop magnetic stirrer used in electrocoagulation? Enhance Wastewater Treatment Efficiency

- Why quartz is used in making laboratory ware? Unlock Superior Performance for Extreme Conditions

- How do you clean Rotavapor? A Step-by-Step Guide to Maintain Analytical Purity

- Why is a forced-air drying oven used at 120 °C for molybdenum catalysts? Preserve Your Catalyst’s Pore Structure

- How should a suitable sample be selected and secured in the holder before an experiment? Ensure Unshakeable Stability for Reliable Data