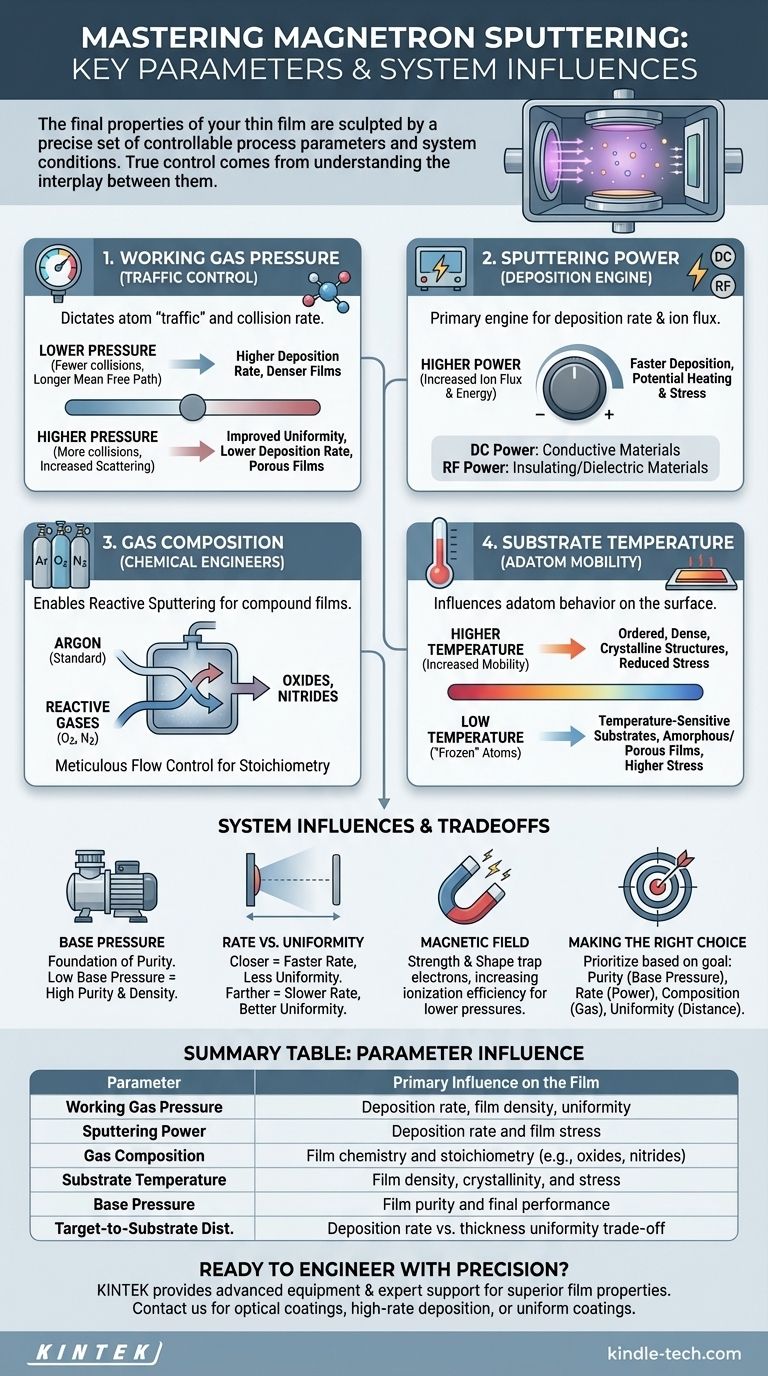

In magnetron sputtering, the final properties of your thin film are determined by a precise set of controllable process parameters. The most critical of these are the working gas pressure, the power applied to the sputtering target, the composition of the process gas, and the temperature of the substrate during deposition. Mastering these variables is the key to achieving your desired film characteristics.

True control over thin film deposition is not about any single parameter, but about understanding the interplay between them. Each setting adjusts the energy and flux of atoms arriving at your substrate, which directly sculpts the final film's density, uniformity, stress, and purity.

The Core Process Parameters: Your Primary Levers of Control

The sputtering chamber is a dynamic environment. The following parameters are the main inputs you will use to direct the process and engineer the outcome.

Working Gas Pressure

The pressure of the working gas (typically Argon) inside the chamber dictates the "traffic" that sputtered atoms must navigate.

A lower pressure means fewer gas atoms, resulting in a longer mean free path. Sputtered atoms travel more directly to the substrate, leading to a higher deposition rate and potentially denser films.

A higher pressure increases the chance of collisions between sputtered atoms and gas atoms. This scattering effect can improve coating uniformity over complex shapes but often reduces the deposition rate and can lead to less dense, more porous films.

Sputtering Power

Power applied to the target is the primary engine of the deposition rate. It determines how many ions are energized to strike the target and dislodge material.

Higher power increases the ion flux and energy, leading to a faster deposition rate. However, excessive power can also cause unwanted heating of the substrate and may alter the film's internal stress.

The type of power is also critical. Direct Current (DC) power is used for conductive target materials. Radio Frequency (RF) power is necessary for sputtering insulating or dielectric materials, as it prevents charge buildup on the target surface.

Gas Composition and Flow Rate

While Argon is the standard sputtering gas, adding other gases can fundamentally change the film's chemistry in a process called reactive sputtering.

Introducing a small amount of oxygen or nitrogen allows you to deposit oxides (like SiO₂) or nitrides (like TiN) from a pure metal target. The flow rate of these reactive gases must be meticulously controlled to achieve the desired film stoichiometry.

Substrate Temperature

The temperature of the substrate directly influences the behavior of atoms once they land on the surface.

Higher temperatures give the arriving atoms (adatoms) more surface mobility. This allows them to settle into more ordered, dense, and crystalline structures, which can also help reduce intrinsic film stress.

Conversely, low-temperature deposition "freezes" atoms where they land, which can be necessary for temperature-sensitive substrates but may result in more amorphous or porous films with higher internal stress.

Understanding the Trade-offs and System Influences

Beyond the primary process controls, the physical setup of your system and the initial conditions create a framework of constraints and opportunities.

Base Pressure: The Foundation of Purity

Before introducing the working gas, the chamber is evacuated to a base pressure. This initial vacuum quality is paramount.

A poor (high) base pressure means residual contaminants like water vapor and oxygen will be incorporated into your film, compromising its purity, density, and performance. A low base pressure is the non-negotiable starting point for high-quality films.

The Rate vs. Uniformity Dilemma

The target-to-substrate distance presents a classic engineering trade-off.

Placing the substrate closer to the target increases the deposition rate but can harm the film's thickness uniformity. Increasing the distance improves uniformity by allowing the sputtered material to spread out more evenly, but this comes at the cost of a significantly lower deposition rate.

Magnetic Field Strength

While not a typical process parameter you adjust daily, the design of the magnetron itself is crucial. The strength and shape of the magnetic field trap electrons near the target surface.

This trapping action dramatically increases the ionization efficiency of the working gas, which is what allows sputtering to operate at low pressures. A stronger magnetic field generally leads to a denser plasma and a higher sputtering rate for a given power.

Making the Right Choice for Your Film

Your specific goal dictates how you should prioritize and balance these parameters.

- If your primary focus is a dense, high-purity optical or electronic film: Prioritize achieving the lowest possible base pressure and consider moderate substrate heating to improve film structure.

- If your primary focus is a high deposition rate for a thick coating: Maximize sputtering power and optimize the working pressure to be as low as possible without compromising plasma stability.

- If your primary focus is depositing a stoichiometric compound (e.g., an oxide): Meticulously control the partial pressure and flow rate of your reactive gas, as this is the most sensitive parameter.

- If your primary focus is uniformly coating a large or complex part: Increase the target-to-substrate distance and ensure you have effective substrate rotation.

By systematically controlling these interconnected variables, you move from simply depositing a film to engineering its properties with precision.

Summary Table:

| Parameter | Primary Influence on the Film |

|---|---|

| Working Gas Pressure | Deposition rate, film density, and uniformity |

| Sputtering Power | Deposition rate and film stress |

| Gas Composition | Film chemistry and stoichiometry (e.g., oxides, nitrides) |

| Substrate Temperature | Film density, crystallinity, and stress |

| Base Pressure | Film purity and final performance |

| Target-to-Substrate Distance | Deposition rate vs. thickness uniformity trade-off |

Ready to engineer your thin films with precision?

At KINTEK, we specialize in providing the advanced lab equipment and expert support you need to master magnetron sputtering. Whether your goal is high-purity optical coatings, high-rate deposition, or uniform coating of complex parts, our solutions are designed to help you achieve optimal results.

We help you:

- Achieve superior film density and purity.

- Optimize deposition rates for your specific application.

- Precisely control reactive processes for compound films.

Let's discuss your laboratory's specific needs. Contact our experts today to find the perfect sputtering solution for your research or production.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- What are the three types of tempering? Choose the Right Process for Hardness vs. Toughness

- What is the sizing process in sintering? Master Dimensional Control for Precision Parts

- What is the most efficient way to remove excess low boiling point solvent from a high boiling point material? Use Rotary Evaporation for Fast, Safe Removal

- What are the advantages of plastic pyrolysis process? Unlock Value from Waste Plastic

- What are the benefits of biomass pellets? A Sustainable, Cost-Effective Fuel Alternative

- What is the mechanism of SPS? Unlock Rapid, Low-Temperature Densification

- Why should hesperidin samples be stored in amber glass and ULT freezers? Preserve Bioactivity and Sample Integrity

- What are the advantages of using specialized supports in out-of-pack aluminizing? Achieve a Pristine Surface Finish