Operating a vacuum tube furnace at 1450°C introduces significant operational constraints. At this demanding temperature, the furnace is pushed to its material limits. The maximum inner diameter of the work tube is restricted to 88 mm, the tube itself must be treated as a consumable with a limited lifetime, and process cycles are limited to slow thermal ramps.

The core issue at 1450°C is a fundamental shift in the furnace's operation: the central work tube degrades rapidly, transforming from a durable component into a regular consumable. This reality impacts everything from sample size and process time to operational cost and reliability.

The Core Limitations at 1450°C

Pushing a vacuum tube furnace to such high temperatures places extreme stress on its core component, the work tube, leading to several practical limitations.

The Work Tube Becomes a Consumable

At 1450°C, the material of the work tube (often a ceramic like alumina) is near its operational ceiling. This high thermal load causes rapid degradation, making it brittle and susceptible to failure.

Consequently, the tube is no longer a long-term part of the furnace but a consumable item with a limited lifetime that must be replaced periodically.

Severe Size Restrictions

The physical stresses at this temperature dictate a smaller, more robust tube design. For this reason, the maximum inner diameter is strictly limited to 88 mm.

This directly constrains the size, geometry, and volume of the parts or materials that can be processed in a single run.

Slow Thermal Ramping

To prevent thermal shock that could crack the already-stressed work tube, the furnace must be operated with low-temperature ramps.

This means heating and cooling cycles are significantly slower. This not only increases overall process time but may also be unsuitable for applications requiring rapid quenching or specific thermal profiles.

Understanding the Context: Lab vs. Industrial Furnaces

The limitations of a tube furnace at 1450°C become clearer when compared to furnaces specifically designed for such demanding applications.

The Tube Furnace: Designed for Versatility

Vacuum tube furnaces are typically designed for periodic operation in laboratories, research units, and small-scale industrial settings.

Their strength lies in versatility for applications like elemental analysis, annealing small parts, and testing new materials at a wide range of lower temperatures. At 1450°C, they are operating at the absolute edge of their capability.

The Alternative: Metallic Hot Zone Furnaces

For demanding aerospace or research applications, a different class of furnace is used. These systems feature a metallic thermal chamber built from materials like molybdenum.

Instead of fiber insulation, they use multiple layers of reflective shielding to manage heat. This design avoids materials that can trap moisture and ensures a purer vacuum environment, making it far more robust and reliable for sustained high-temperature work.

The Practical Trade-offs and Risks

Choosing to operate a tube furnace at its maximum rated temperature involves accepting significant risks and trade-offs that are not present at lower temperatures.

Increased Operational Costs

Factoring in the cost of frequent tube replacements is critical. What may seem like a lower initial investment can quickly become more expensive due to the ongoing need for these consumable components.

Process Reliability and Downtime

Each tube replacement introduces downtime for installation and conditioning. Furthermore, as a tube degrades over its short lifespan, its thermal properties can shift, potentially impacting the repeatability and consistency of your results.

Risk of Catastrophic Failure

A degraded work tube can crack or fail during a run. This leads to a sudden loss of vacuum, which can ruin the material being processed and potentially damage heating elements or other furnace components.

Making the Right Choice for Your Application

To select the appropriate equipment, you must align the tool's capabilities with your primary operational goal.

- If your primary focus is research on small samples with a flexible schedule: A tube furnace can be viable, provided you budget for regular tube replacement and can tolerate longer process times.

- If your primary focus is processing larger components or production throughput: The 88 mm size limit and the consumable nature of the tube make this furnace entirely unsuitable; a dedicated metallic hot zone furnace is the correct choice.

- If your primary focus is process repeatability for sensitive materials: A purpose-built, all-metal vacuum furnace provides the stability and high-purity environment necessary for consistent, reliable results at these temperatures.

Ultimately, understanding these limitations ensures you select a tool that accelerates your work rather than one that constrains it.

Summary Table:

| Limitation | Impact at 1450°C |

|---|---|

| Work Tube Degradation | Becomes a consumable with limited lifetime |

| Size Restriction | Max inner diameter limited to 88 mm |

| Thermal Ramping | Requires slow heating/cooling cycles |

| Process Reliability | Risk of inconsistent results and downtime |

| Operational Cost | Increased cost from frequent tube replacement |

Struggling with high-temperature furnace limitations? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the right furnace for your application, whether it's a vacuum tube furnace for versatile research or a more robust solution for demanding 1450°C processes. Contact us today to discuss your specific requirements and ensure reliable, repeatable results!

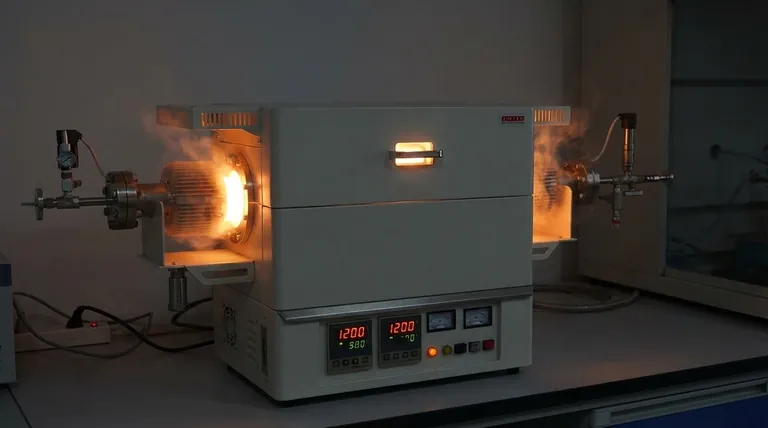

Visual Guide

Related Products

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the primary purpose of using vacuum-sealed quartz tubes? Ensure High-Purity Battery Material Synthesis

- How does the vacuum environment impact sintering of diamond-copper composites? Protect Against Thermal Damage

- What is the role of a HPHT tube furnace in HTGR simulation? Achieve Precise Nuclear Environment Replications

- What is the role of high-purity quartz tubes in vacuum chromization? Secure High-Performance Superalloy Coating

- What are the advantages of using a vacuum tube furnace for SiCw/2024Al composites? Ensure Pure, High-Strength Results.