The fundamental limits of heat treatment are dictated by three interconnected factors: the inherent chemical composition of the material, the physical size and geometry of the part, and the rate at which heat can be removed during the quenching process. If any one of these is mismatched with the desired outcome, the process will fail to achieve the target properties, or worse, may lead to cracking and catastrophic failure.

Heat treatment is fundamentally a race against time. The goal is to cool a metal quickly enough to lock in a desirable, hard crystal structure before it can transform into a softer, more stable one. Every limitation is a factor that either slows this cooling process or creates unacceptable side effects like stress and distortion.

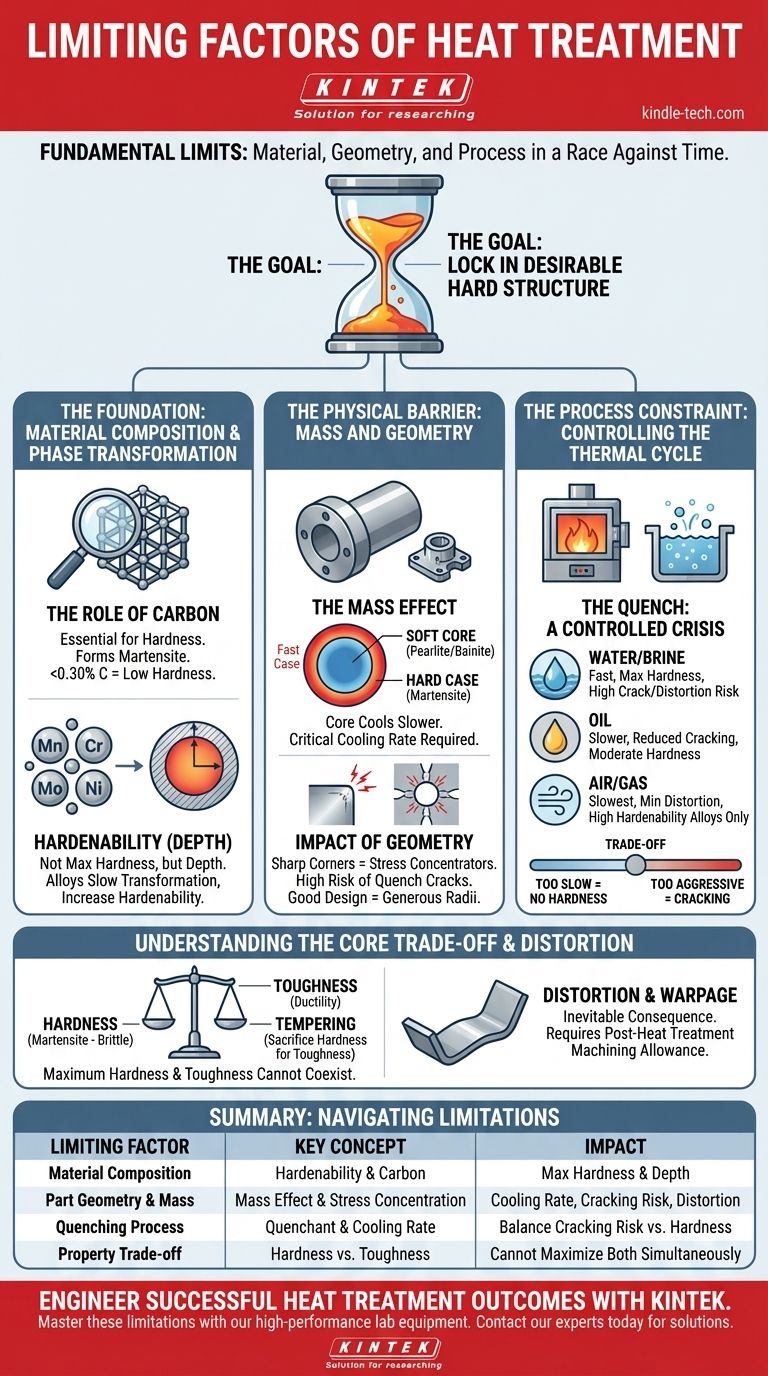

The Foundation: Material Composition and Phase Transformation

The potential of any heat treatment process is established before the part ever sees a furnace. It is locked into the alloy's chemistry.

The Role of Carbon

The single most important element for hardening steel is carbon. It is the primary agent responsible for the formation of martensite, the hard, brittle microstructure desired from quenching.

Without sufficient carbon (typically above 0.30%), a plain steel simply cannot achieve significant hardness, no matter how aggressively it is quenched. This is the most fundamental limitation of all.

The Concept of Hardenability

Hardenability is not a measure of maximum achievable hardness, but rather a measure of the depth to which a steel can be hardened. An alloy with low hardenability might only harden a few millimeters deep, while one with high hardenability can harden through its entire cross-section.

Alloying elements like manganese, chromium, molybdenum, and nickel are the key to increasing hardenability. They act to slow down the steel's internal transformation to softer structures, giving you more time during the quench to cool the core of the part and still form martensite.

The Physical Barrier: Mass and Geometry

A part's physical shape and size create significant real-world constraints on the theoretical perfection of a heat treatment cycle.

The Mass Effect

The core of a thick or massive part will always cool slower than its surface. This is a simple law of thermal physics.

If the cooling rate at the core drops below the critical cooling rate required for that specific alloy, the core will not form hard martensite. Instead, it will form softer microstructures like pearlite or bainite, resulting in a part with a hard case and a soft, weak core. This "mass effect" is a primary reason why high-hardenability alloys are necessary for large components.

The Impact of Geometry

Sharp internal corners, drastic changes in thickness, and small holes act as stress concentrators.

During the intense thermal shock of quenching, these features become points where stress multiplies to extreme levels. If the stress exceeds the material's strength, quench cracks will form, rendering the part useless. Good design for heat treatment involves using generous radii and avoiding abrupt changes in cross-section.

The Process Constraint: Controlling the Thermal Cycle

Even with the right material and design, the process itself can be the limiting factor.

The Quench: A Controlled Crisis

The quench is the most critical and dangerous stage. The choice of quenching medium (the "quenchant") is a balancing act.

- Water/Brine: Extremely fast cooling, providing maximum hardness but also maximum thermal shock and a high risk of cracking and distortion.

- Oil: A slower quench than water, reducing the risk of cracking. Often used for higher-hardenability alloys that don't require an extreme cooling rate.

- Air/Gas: The slowest quench, used for highly alloyed "air-hardening" tool steels. It produces the least amount of distortion but is only effective on materials with very high hardenability.

Choosing a quench that is too slow for the alloy and part size will result in a failure to harden. Choosing one that is too aggressive will result in cracking.

Understanding the Core Trade-off: Hardness vs. Brittleness

Achieving the desired properties is never about maximizing a single attribute. It is always a compromise.

Hardness vs. Toughness

The as-quenched martensitic structure is extremely hard but also very brittle, making it unsuitable for almost any practical application.

This is why tempering is a mandatory post-quenching step. Tempering is a low-temperature heat treatment that sacrifices some hardness to gain a significant and necessary increase in toughness and ductility. The ultimate limitation, therefore, is that you cannot have maximum hardness and maximum toughness simultaneously.

Distortion and Warpage

Distortion is not an accident; it is an inevitable consequence of heat treatment. The thermal stresses from quenching and the volume changes from phase transformation will always cause a part to move.

Long, thin parts are especially susceptible to warpage. While proper fixturing and stress-relieving cycles can minimize distortion, it can never be eliminated entirely. This limitation must be accounted for by leaving extra material for final machining after heat treatment.

Making the Right Choice for Your Goal

The right approach depends entirely on your specific objective and the constraints you are working within.

- If your primary focus is achieving maximum hardness in a complex shape: Choose a high-hardenability alloy steel and a slower, less severe quench like oil to minimize the risk of quench cracking.

- If your primary focus is hardening a very large cross-section: You must use an alloy with high hardenability (containing elements like Cr, Mo, Ni) to ensure the core cools fast enough to harden.

- If your primary focus is minimizing distortion: Select an air-hardening tool steel if possible, or use a slower quench combined with proper support fixturing and a pre-hardening stress relief cycle.

- If your primary focus is cost and you are using a low-hardenability carbon steel: You are limited to thin sections and must use a very aggressive quench like water, accepting the higher risk of distortion.

By understanding these limitations, you move from hoping for a good result to engineering one.

Summary Table:

| Limiting Factor | Key Concept | Impact on Heat Treatment |

|---|---|---|

| Material Composition | Hardenability & Carbon Content | Determines maximum achievable hardness and depth of hardening. |

| Part Geometry & Mass | Mass Effect & Stress Concentration | Influences cooling rate, risk of cracking, and distortion. |

| Quenching Process | Quenchant Selection & Cooling Rate | Balances the risk of cracking against achieving target hardness. |

| Property Trade-off | Hardness vs. Toughness | Maximum hardness and toughness cannot be achieved simultaneously. |

Engineer successful heat treatment outcomes with KINTEK.

Navigating the complex interplay of material composition, part geometry, and quenching parameters is critical to achieving your desired material properties without failure. KINTEK specializes in providing the high-performance lab equipment—from precise furnaces to controlled quenching systems—that empowers you to master these limitations.

Whether you are developing new alloys, hardening complex components, or optimizing for minimal distortion, our solutions deliver the reliability and control your laboratory needs.

Contact our experts today to discuss how KINTEK's equipment can help you overcome heat treatment challenges and achieve consistent, high-quality results.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the temperature of the annealing furnace? It Depends on Your Material and Process

- How does vacuum brazing work? Achieve Superior, Flux-Free Metal Joining

- What is the difference between vertical and horizontal furnace semiconductors? Unlock Superior Yield and Uniformity

- What is the process of vacuum evaporation? A Guide to Thin-Film Deposition

- What is the function of a precision isothermal heating furnace in inducing secondary phase precipitation? Optimize Microstructures

- What is debinding in 3D printing? The Essential Step for Strong Metal & Ceramic Parts

- What is a laboratory furnace? The Essential Guide to High-Temperature Precision

- Which furnace is used for heating metals? Match the Right Technology to Your Metalworking Goal