At its core, a high-temperature muffle furnace is an integrated system built from three primary components: an inner heating chamber, the heating elements that generate the temperature, and an electronic control unit that manages the process. These parts are contained within an insulated external body or housing that ensures both thermal efficiency and safety.

A muffle furnace is defined not just by its parts, but by their quality and integration. The precision of the control unit, the durability of the heating elements, and the effectiveness of the insulation work together to create the stable, uniform, and safe high-temperature environment required for critical processes.

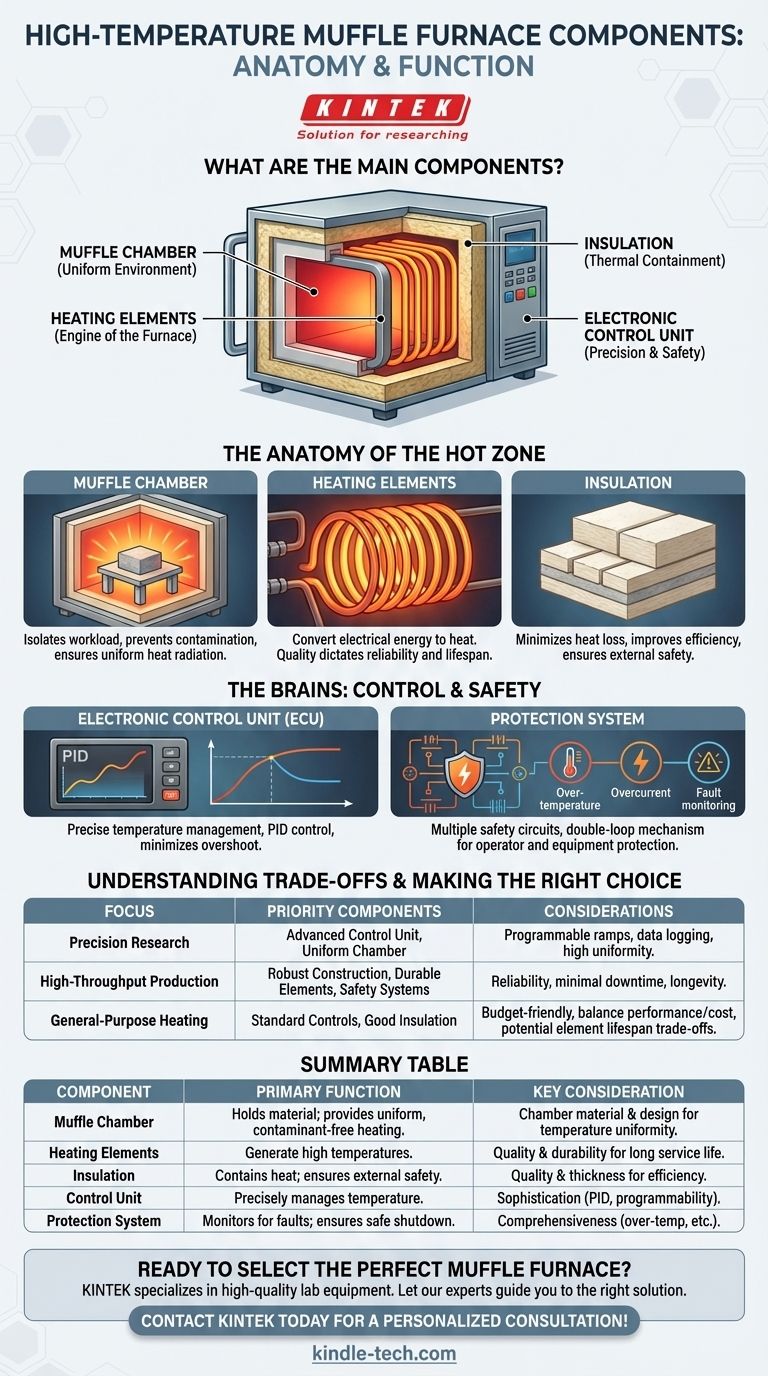

The Anatomy of the Hot Zone

The "hot zone" is the heart of the furnace, where the thermal work is done. Its design and materials directly dictate the furnace's performance, uniformity, and efficiency.

The Muffle Chamber: Creating a Uniform Environment

The central component is the muffle, a refractory-lined chamber that holds the materials being heated.

Its primary purpose is to isolate the workload from direct contact with the heating elements. This separation prevents contamination and ensures heat is radiated evenly from all sides, creating a highly uniform temperature environment.

Inside the chamber, supports or frames are often used to securely position the items being treated within the most stable heating area.

The Heating Element: The Engine of the Furnace

Surrounding the muffle chamber are the heating elements. These components convert electrical energy into the intense heat required for high-temperature applications.

The quality, material, and mass of the heating elements are critical indicators of the furnace's reliability and lifespan. Robust elements can withstand repeated thermal cycling without degrading quickly.

The Insulation: Containing Extreme Temperatures

The entire hot zone is encased in layers of high-performance insulation, typically made of refractory ceramic fiber or bricks.

This insulation is crucial for minimizing heat loss, which improves energy efficiency and allows the furnace to maintain stable high temperatures. It also keeps the external housing cool to the touch, ensuring operator safety.

The Brains of the Operation: Control and Safety

While the hot zone creates the heat, the electronic systems provide the intelligence and safety needed for precise, repeatable results. A furnace is only as good as its ability to be controlled.

The Electronic Control Unit: Precision and Reliability

The electronic control unit is the furnace's brain. It uses intelligent instruments, such as a PID (Proportional-Integral-Derivative) controller, to manage the temperature precisely.

Users set a target temperature, and the controller modulates power to the heating elements (often using a thyristor) to reach and hold that temperature with minimal overshoot or fluctuation.

The Protection System: Ensuring Safe Operation

A robust furnace includes an integrated protection system with multiple safety circuits. This is non-negotiable for protecting the operator, the sample, and the equipment itself.

These systems monitor for faults like over-temperature, overcurrent, phase loss, and heating element failure. A double-loop protection mechanism ensures that if one control fails, a backup system can safely shut down the furnace.

Understanding the Trade-offs

Choosing or evaluating a muffle furnace involves balancing performance, longevity, and cost. The quality of the core components is where these trade-offs are most apparent.

Insulation Quality vs. Efficiency

Higher-grade, thicker insulation provides superior thermal efficiency and stability. This reduces electricity consumption and improves process repeatability but comes at a higher initial cost.

Control System Sophistication

A basic controller can hold a temperature, but an advanced unit offers programmable heating ramps, data logging, and more sophisticated safety interlocks. This added precision is critical for sensitive materials but may be overkill for simple applications.

Heating Element Durability

Lower-cost heating elements are more susceptible to burnout, especially under frequent, rapid heating cycles. Investing in higher-quality elements made from superior materials results in significantly longer service life and less downtime.

Making the Right Choice for Your Application

Your final evaluation should be guided by your primary goal.

- If your primary focus is precision research and material analysis: Prioritize a furnace with an advanced, programmable control unit and a chamber designed for maximum temperature uniformity.

- If your primary focus is high-throughput production: Emphasize robust construction, high-durability heating elements, and comprehensive safety systems to ensure reliability and minimize downtime.

- If your primary focus is general-purpose heating on a budget: A furnace with standard controls and good-quality insulation is effective, but be mindful of the potential trade-offs in element lifespan and temperature stability.

Understanding these core components empowers you to look beyond simple specifications and evaluate a furnace based on its true performance, safety, and long-term value.

Summary Table:

| Component | Primary Function | Key Consideration |

|---|---|---|

| Muffle Chamber | Holds material; provides uniform, contaminant-free heating. | Chamber material and design for temperature uniformity. |

| Heating Elements | Generate the high temperatures required for processing. | Quality and durability for long service life and reliability. |

| Insulation | Contains heat for efficiency and ensures external safety. | Quality and thickness for thermal efficiency and stability. |

| Control Unit | Precisely manages temperature and furnace operation. | Sophistication (e.g., PID, programmability) for process control. |

| Protection System | Monitors for faults and ensures safe shutdown if needed. | Comprehensiveness (over-temperature, overcurrent, etc.). |

Ready to Select the Perfect Muffle Furnace for Your Lab?

Understanding the components is the first step. Choosing the right furnace for your specific application—whether it's precision research, high-throughput production, or general-purpose heating—is critical to your success.

KINTEK specializes in providing high-quality lab equipment, including robust and reliable muffle furnaces. We can help you navigate the trade-offs between performance, durability, and cost to find the ideal solution that delivers long-term value and ensures the safety and repeatability of your processes.

Let our experts guide you to the right equipment. Contact KINTEL today for a personalized consultation!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Is a muffle furnace used for ash determination? Discover Its Critical Role in Accurate Analysis

- Why is a muffle furnace essential for determining the ash content of Napier grass? Ensure Accurate Biomass Analysis

- What is a muffle furnace for laboratory use? A Guide to Contaminant-Free High-Temperature Processing

- How do you run a muffle furnace? Master the Step-by-Step Process for Safe, Precise Results

- What is powder sintering process? A Guide to Solid-State Metal & Ceramic Fabrication

- How does a muffle furnace facilitate ZrW2O8 powder synthesis? Optimize Negative Thermal Expansion (NTE) Material Quality

- Why is it necessary to control the temperature program of a debinding furnace? Prevent Cracks in Ti/Al2O3 Composites

- What is the primary application of high-precision furnaces in the solid-state synthesis of mixed niobates like La1-xYxNbO4?