At its core, Chemical Vapor Deposition (CVD) is not a single process but a family of techniques. The primary methods are distinguished by their operating pressure and the type of energy used to initiate the chemical reaction. Key variations include Atmospheric Pressure CVD (APCVD), Low-Pressure CVD (LPCVD), and Plasma-Enhanced CVD (PECVD), each tailored for different material properties and substrate limitations.

The choice of a specific CVD method is a strategic trade-off. You are balancing the need for deposition speed, film quality and uniformity, and the temperature sensitivity of your substrate. Understanding these trade-offs is the key to selecting the right tool for your specific engineering goal.

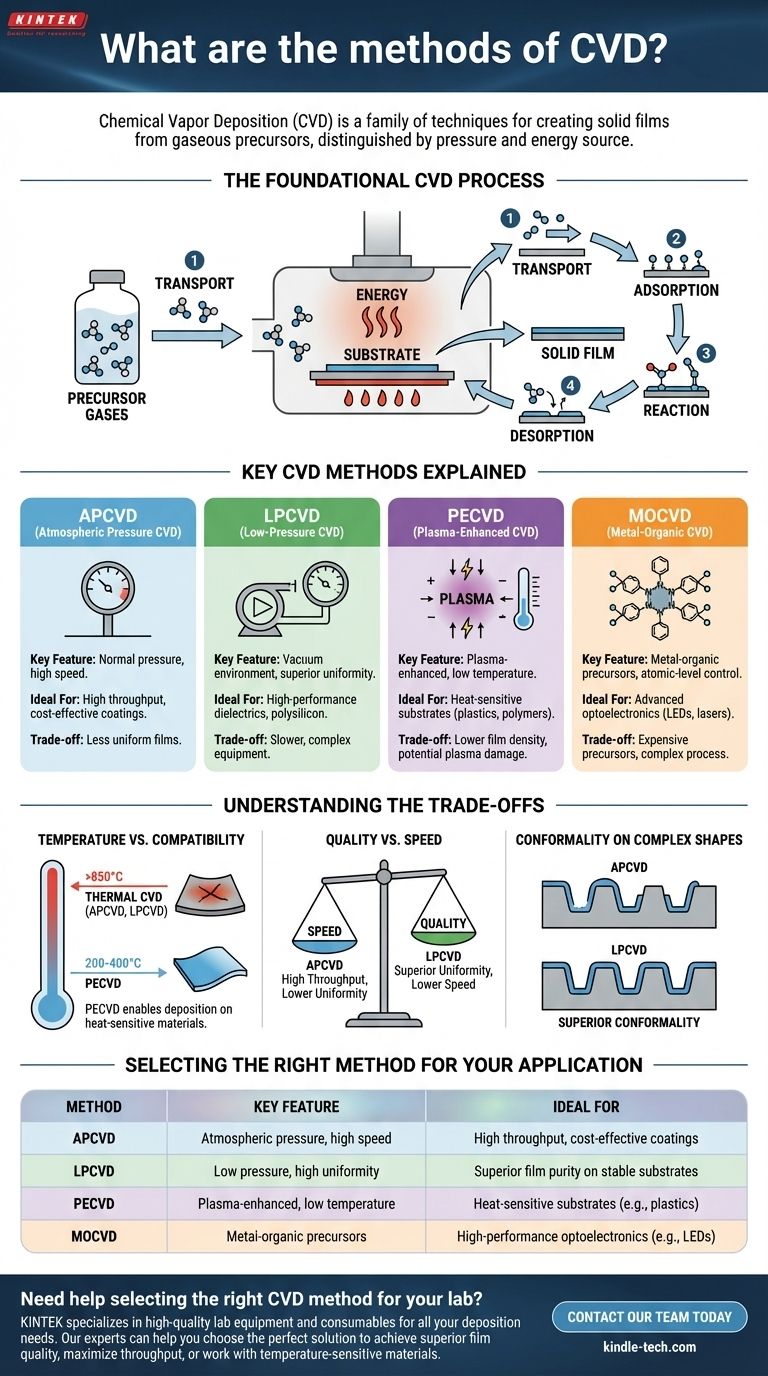

The Foundational CVD Process

Before comparing methods, it's crucial to understand the universal steps that define all CVD processes. Every technique involves a sequence of events to build a solid film from gaseous precursors.

From Gas to Solid Film

A CVD process begins by introducing precursor gases into a reaction chamber containing the object to be coated, known as the substrate.

Energy, typically heat, is applied to the system. This energy drives a chemical reaction, causing the precursor gases to decompose and deposit a thin, solid film onto the heated substrate surface.

The Key Stages of Deposition

The process can be broken down into discrete steps:

- Transport: Precursor gases are transported into the reaction zone.

- Adsorption: Gas molecules attach to the substrate's surface.

- Reaction: Chemical reactions occur on the surface, breaking down the precursors and forming the desired solid film.

- Desorption: Gaseous by-products from the reaction detach from the surface and are exhausted from the chamber.

Key CVD Methods Explained

The various CVD methods are essentially different ways to control the environment in which these fundamental steps occur. Each method optimizes for a different outcome.

Atmospheric Pressure CVD (APCVD)

APCVD is performed at normal atmospheric pressure. Because it doesn't require expensive vacuum systems, the equipment is simpler and the process is faster.

This makes it a cost-effective choice for applications where high throughput is critical and perfect film uniformity is not the primary concern.

Low-Pressure CVD (LPCVD)

LPCVD operates in a vacuum, at significantly reduced pressures. This reduction in pressure increases the mean free path of gas molecules, meaning they can travel further before colliding.

The result is a highly uniform and pure film that can conformally coat even complex, three-dimensional structures. This is a workhorse method in the semiconductor industry for producing high-quality dielectric and polysilicon layers.

Plasma-Enhanced CVD (PECVD)

PECVD uses an electric field to generate a plasma (an ionized gas) within the chamber. This plasma provides the energy needed to break down the precursor gases, rather than relying solely on high heat.

The primary advantage is a dramatically lower deposition temperature (e.g., 200-400°C instead of 850°C+). This makes PECVD essential for depositing films on substrates that cannot withstand high heat, such as plastics or fully processed semiconductor wafers.

Metal-Organic CVD (MOCVD)

MOCVD is a subtype of CVD distinguished by its use of metal-organic precursors. These complex molecules are ideal for depositing high-purity, crystalline compound semiconductor films.

This method offers precise control over film composition and thickness, making it the dominant technology for manufacturing high-performance optoelectronics like LEDs, laser diodes, and high-efficiency solar cells.

Understanding the Trade-offs

Choosing a CVD method requires balancing competing factors. The "best" method is entirely dependent on the application's constraints and desired outcomes.

Temperature vs. Substrate Compatibility

Traditional thermal CVD (APCVD, LPCVD) requires very high temperatures (often over 850°C), which can damage or warp many materials. This is the single biggest constraint for thermal CVD.

Methods like PECVD directly solve this problem by using plasma energy instead of thermal energy, enabling deposition on a much wider range of heat-sensitive materials.

Quality vs. Speed

There is often a direct trade-off between deposition speed and film quality. APCVD is fast and inexpensive but produces less uniform films.

LPCVD, by contrast, is slower and requires vacuum equipment, but it yields exceptional purity and uniformity, which is non-negotiable for high-performance microelectronics.

Conformality on Complex Shapes

Conformality is the ability of a film to coat all surfaces of a textured object with uniform thickness.

Due to the enhanced gas diffusion at low pressures, LPCVD offers superior conformality compared to APCVD, making it the preferred choice for coating deep trenches or complex topographies in microfabrication.

Selecting the Right Method for Your Application

Your choice should be guided by your primary technical and business objectives.

- If your primary focus is high throughput and low cost: APCVD is often sufficient for protective coatings or simple films where perfect quality is secondary.

- If your primary focus is superior film purity and uniformity on stable substrates: LPCVD is the industry standard for high-performance dielectrics and polysilicon in microelectronics.

- If your primary focus is depositing films on temperature-sensitive materials: PECVD is the clear and often only choice, enabling coating on polymers, plastics, or completed devices.

- If your primary focus is fabricating advanced optoelectronics (e.g., LEDs): MOCVD provides the atomic-level control over composition required for these demanding applications.

By matching the capabilities of each method to your specific goal, you can leverage Chemical Vapor Deposition to precisely engineer materials for nearly any purpose.

Summary Table:

| Method | Key Feature | Ideal For |

|---|---|---|

| APCVD | Atmospheric pressure, high speed | High throughput, cost-effective coatings |

| LPCVD | Low pressure, high uniformity | Superior film purity on stable substrates |

| PECVD | Plasma-enhanced, low temperature | Heat-sensitive substrates (e.g., plastics) |

| MOCVD | Metal-organic precursors | High-performance optoelectronics (e.g., LEDs) |

Need help selecting the right CVD method for your lab's specific application?

KINTEK specializes in providing high-quality lab equipment and consumables for all your deposition needs. Our experts can help you choose the perfect solution to achieve superior film quality, maximize throughput, or work with temperature-sensitive materials.

Contact our team today to discuss your project requirements and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- Describe the structure of a process chamber used for High-Density Plasma CVD (HDP-CVD)? Key Design Features Explained

- What is the function of high-temperature metal filaments in HFCVD? Catalyzing Diamond Growth Success

- How is graphene made from CVD? Unlocking Industrial-Scale Production of High-Quality Graphene

- What is chemical Vapour deposition for nanomaterials? A Guide to Bottom-Up Nanomaterial Synthesis

- How does RF magnetron sputtering work? A Complete Guide to Thin-Film Deposition

- What is the role of a controlled atmosphere reactor in the synthesis of nano-carbon-cement? Master CVD Nanotech

- How does the heating system of a CVD furnace assist in catalyst pretreatment? Optimize Graphene Synthesis on Steel

- What are the disadvantages of graphene CVD? Challenges in Achieving Perfect Monolayer Uniformity