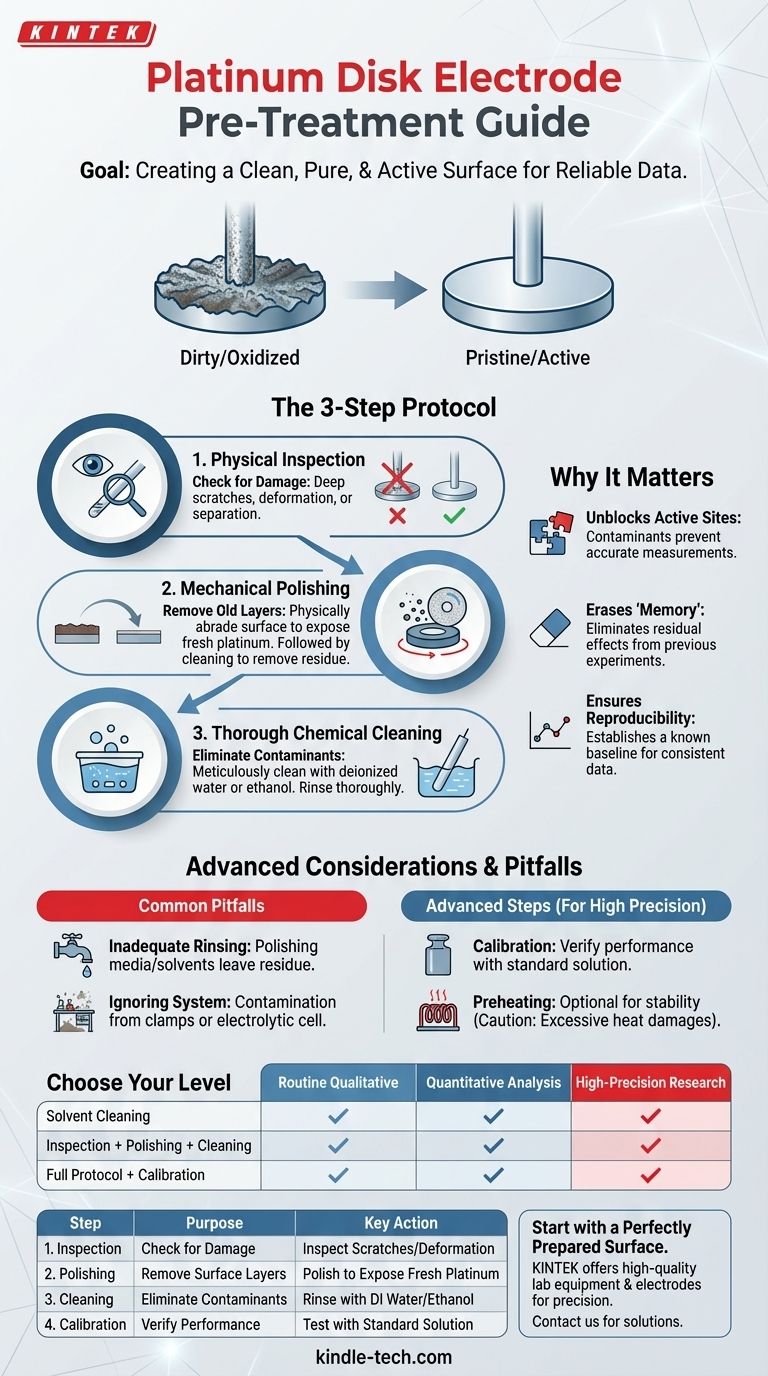

The necessary pre-treatment for a platinum disk electrode is a multi-step process focused on creating a clean, pure, and electrochemically active surface. The core sequence involves a physical inspection for damage, mechanical polishing to remove old surface layers and contaminants, and a thorough chemical cleaning with solvents like deionized water or ethanol to eliminate any residual polishing material or impurities. For experiments demanding high accuracy, this is often followed by electrode calibration.

The core problem is that a platinum electrode's surface is highly sensitive to its history, readily accumulating oxides and contaminants that invalidate experimental results. Proper pre-treatment is not just about cleaning; it's a systematic protocol to reset the electrode to a known, reproducible baseline state, which is the foundation of all reliable electrochemical data.

The Goal: A Pristine and Reproducible Surface

The entire pre-treatment protocol is designed to address one fundamental challenge: the platinum surface is not inert. Its electrochemical behavior is dictated by its immediate surface condition, which can be easily compromised.

Why Surface Condition is Critical

Any contaminants, such as grease from handling, adsorbed species from the air, or oxides from previous experiments, will block the active sites on the electrode. This leads to inaccurate and non-repeatable measurements.

The Problem of Electrode "Memory"

An electrode effectively "remembers" its last use. Residual materials or surface changes from a previous experiment will interfere with the next one. The goal of pre-treatment is to erase this memory completely.

The Step-by-Step Pre-Treatment Protocol

A disciplined, sequential approach ensures that each step prepares the electrode for the next, culminating in a pristine surface ready for your experiment.

Step 1: Physical Inspection

Before any other procedure, carefully inspect the electrode. Look for deep scratches, physical deformation, or signs that the platinum disk is separating from its insulating shroud. A physically damaged electrode cannot provide a well-defined surface area and should be repaired or replaced.

Step 2: Mechanical Polishing

The most critical step for removing the existing surface layer—including any oxides or stubborn contaminants—is mechanical polishing. This process physically abrades the top layer of the platinum to expose a fresh, uniform surface.

After polishing, it is imperative to remove all polishing residue.

Step 3: Thorough Chemical Cleaning

Following polishing, the electrode must be meticulously cleaned to remove any remaining polishing media and other impurities. This is typically done with a solvent like deionized water or ethanol.

Thorough rinsing is key. For best results, this cleaning step can be performed in an ultrasonic bath to dislodge any fine particles from the surface. Finally, gently dry the electrode with filter paper or a clean cloth.

Common Pitfalls and Advanced Considerations

Achieving a perfect surface requires avoiding common mistakes and knowing when to apply additional steps. These considerations separate routine work from high-precision results.

Inadequate Rinsing

A common failure point is leaving behind residue from the polishing or cleaning stages. If polishing media or solvents are not completely removed, they become the new contaminants on your "clean" electrode.

Ignoring the Broader System

The electrode is only as clean as its environment. Before an experiment, wipe down the electrode clamps, electrolytic cell, and any fixtures with deionized water or alcohol. This prevents cross-contamination from the experimental setup itself.

The Role of Calibration

For experiments where high accuracy is paramount, calibration is a necessary final step. This involves using a standard solution with a known electrochemical response to verify the electrode's performance according to your instrument's instructions.

When to Consider Preheating

In some high-precision applications, the electrode can be preheated to ensure stable performance. However, this is an advanced technique and must be done carefully, as excessively high temperatures can damage the electrode.

Making the Right Choice for Your Experiment

The required level of pre-treatment depends directly on the sensitivity and goals of your work.

- If your primary focus is routine qualitative analysis: A thorough solvent cleaning with deionized water or ethanol may be sufficient if the electrode is already in good condition.

- If your primary focus is quantitative analysis: The full protocol of inspection, mechanical polishing, and thorough chemical cleaning is non-negotiable for achieving accurate results.

- If your primary focus is high-precision research: The full protocol followed by electrode calibration is essential to ensure your data is both accurate and verifiable.

Ultimately, disciplined and consistent electrode preparation is the foundation upon which all trustworthy electrochemical data is built.

Summary Table:

| Step | Purpose | Key Action |

|---|---|---|

| 1. Physical Inspection | Check for damage | Inspect for scratches or deformation |

| 2. Mechanical Polishing | Remove old surface layers | Polish to expose fresh platinum |

| 3. Chemical Cleaning | Eliminate contaminants | Rinse with deionized water/ethanol |

| 4. Calibration (Optional) | Verify performance | Test with a standard solution |

Ensure your electrochemical experiments start with a perfectly prepared surface. KINTEK specializes in high-quality lab equipment and consumables, including electrodes and cleaning supplies, to support your laboratory's precision needs. Contact our experts today to discuss how our solutions can enhance your data reliability and experimental efficiency!

Visual Guide

Related Products

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- How should a platinum wire/rod electrode be cleaned before use? A Guide to Reliable Electrochemical Data

- What are the performance characteristics of platinum wire/rod electrodes? Unmatched Stability for Your Lab

- What is the application of RRDE? Unlock Quantitative Catalyst and Reaction Insights

- What is a common application for the platinum wire/rod electrode? The Essential Guide to Counter Electrodes

- What is the difference between RDE and RRDE? Unlock Advanced Electrochemical Reaction Analysis