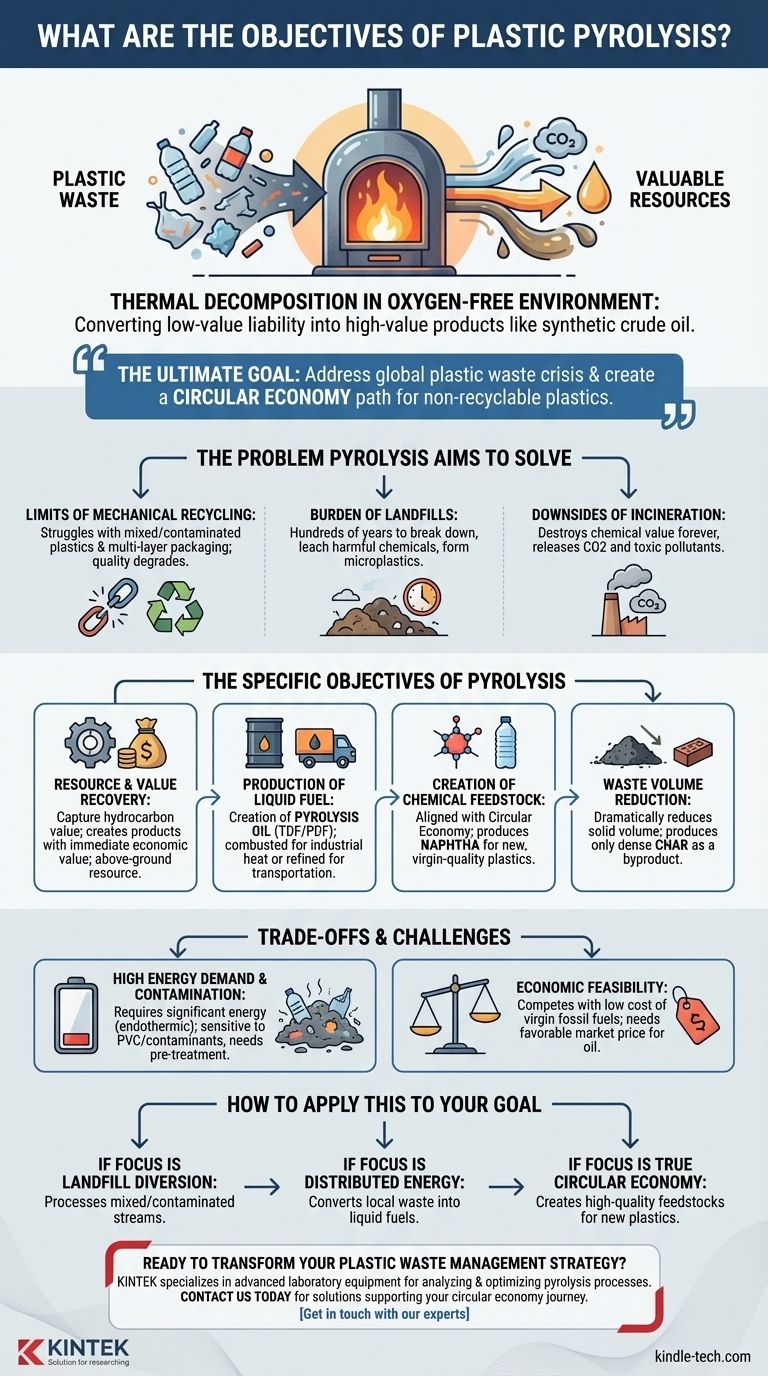

At its core, the primary objective of plastic pyrolysis is to thermally decompose plastic waste in an oxygen-free environment, converting it from a low-value liability into valuable resources. This process aims to recover the energy and chemical building blocks locked within polymer chains, effectively treating plastic not as garbage, but as a synthetic crude oil.

The ultimate goal of plastic pyrolysis is to address the global plastic waste crisis by creating a viable pathway for a circular economy, transforming non-recyclable plastics into fuel, energy, and the raw materials for new products.

The Problem Pyrolysis Aims to Solve

Plastic pyrolysis doesn't exist in a vacuum. It was developed as a potential solution to the significant shortcomings of traditional waste management methods for a large portion of plastic waste.

The Limits of Mechanical Recycling

Mechanical recycling, which involves melting and reforming plastics, is effective for clean, single-stream materials like PET bottles. However, it struggles with mixed plastics, contaminated films, and multi-layer packaging, which constitute a massive portion of waste. The quality of the plastic also degrades with each recycling cycle.

The Burden of Landfills

Plastics that cannot be mechanically recycled are often sent to landfills. Here, they can take hundreds of years to break down, leaching harmful chemicals and fragmenting into microplastics that contaminate soil and water systems. Landfills also represent a permanent loss of the material's inherent value.

The Downsides of Incineration

Incineration, or "waste-to-energy," recovers thermal energy from plastic but destroys the material's chemical value forever. It also releases significant amounts of carbon dioxide and can produce toxic pollutants like dioxins and furans if not strictly controlled, trading a solid waste problem for an air pollution problem.

The Specific Objectives of Pyrolysis

Pyrolysis, as a form of advanced or chemical recycling, offers a different set of outcomes by fundamentally altering the material itself.

Objective 1: Resource and Value Recovery

The principal goal is to capture the value of the hydrocarbons in plastic waste. Instead of being buried or burned, the plastic is deconstructed into its constituent parts, creating products with immediate economic value. This reframes waste plastic as a viable above-ground resource.

Objective 2: Production of Liquid Fuel

A major objective is the creation of pyrolysis oil, often called "Tire Derived Fuel" (TDF) or "Plastic Derived Fuel" (PDF). This synthetic crude oil can be combusted in industrial furnaces and boilers or, with significant upgrading, refined into transportation fuels like diesel and gasoline.

Objective 3: Creation of Chemical Feedstock

This is the most ambitious objective, aligned with a true circular economy. The pyrolysis oil can be purified and processed to yield naphtha and other chemical feedstocks. These feedstocks can then be fed back into steam crackers to produce new, virgin-quality plastics, a process known as "plastic-to-plastic" recycling.

Objective 4: Waste Volume Reduction

By converting solid plastic into liquids and gases, pyrolysis can dramatically reduce the volume of waste requiring disposal. The only solid byproduct is a carbonaceous material called char, which is far more dense and stable than the original plastic feedstock.

Understanding the Trade-offs and Challenges

While the objectives are compelling, achieving them at a commercial scale presents significant technical and economic hurdles. Objectivity requires acknowledging these challenges.

High Energy Demand

Pyrolysis is an endothermic process, meaning it requires a significant input of energy to maintain the high temperatures needed to break down polymer chains. The net energy balance—the energy produced minus the energy consumed—is a critical factor in its environmental and economic viability.

Feedstock Contamination

The process is highly sensitive to the composition of the plastic waste. Contaminants like PVC release chlorine, which can create highly corrosive hydrochloric acid. Food residue, paper, and other materials can negatively impact the quality of the final pyrolysis oil, necessitating costly pre-treatment and post-processing steps.

Economic Feasibility

The economic viability of a pyrolysis plant depends heavily on the market price of its outputs (primarily pyrolysis oil) versus its operational costs. It must compete with the historically low cost of virgin fossil fuels, which is a difficult economic proposition without regulatory support or subsidies.

How to Apply This to Your Goal

Understanding these objectives allows you to see where pyrolysis fits into different strategic goals for waste management and resource recovery.

- If your primary focus is landfill diversion: Pyrolysis is a powerful tool for processing mixed and contaminated plastic streams that are otherwise non-recyclable, directly reducing the burden on landfills.

- If your primary focus is distributed energy production: The technology offers a way to convert local plastic waste into liquid fuels that can power generators, boilers, or industrial furnaces, creating a decentralized energy source.

- If your primary focus is a true circular economy: The ultimate application of pyrolysis is to create high-quality chemical feedstocks that enable the production of new plastics, effectively closing the loop on plastic manufacturing.

Ultimately, plastic pyrolysis is a technology driven by the need to find a more intelligent and sustainable solution for a material that has become a global environmental challenge.

Summary Table:

| Primary Objective | Key Outcome |

|---|---|

| Resource Recovery | Treats plastic waste as a valuable hydrocarbon resource. |

| Fuel Production | Creates pyrolysis oil for industrial energy or transportation fuel. |

| Chemical Feedstock | Produces raw materials for new, virgin-quality plastics. |

| Waste Volume Reduction | Dramatically reduces landfill burden by converting solids to liquids/gas. |

Ready to transform your plastic waste management strategy?

KINTEK specializes in advanced laboratory equipment and consumables for analyzing and optimizing pyrolysis processes. Whether you are researching feedstock quality, optimizing output yields, or scaling up your operation, our precise tools can help you achieve your resource recovery goals.

Contact us today to discuss how our solutions can support your journey toward a circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What is a small pilot scale pyrolysis reactor? Your Guide to Choosing the Right Reactor Design

- What is the difference between roasting and calcination? A Guide to Metallurgical Ore Processing

- What are the examples of the products of pyrolysis? Biochar, Bio-oil, and Syngas Explained

- What is the composition of pyrolysis oil from plastic waste? Unlocking the Potential of Chemical Recycling

- How does a rotary hearth furnace work? Achieve Continuous, High-Volume Thermal Processing

- How does time affect pyrolysis? Master Residence Time to Control Biochar, Bio-Oil, and Syngas Yields

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What is pyrolysis characteristics? Unlocking Waste-to-Energy Potential