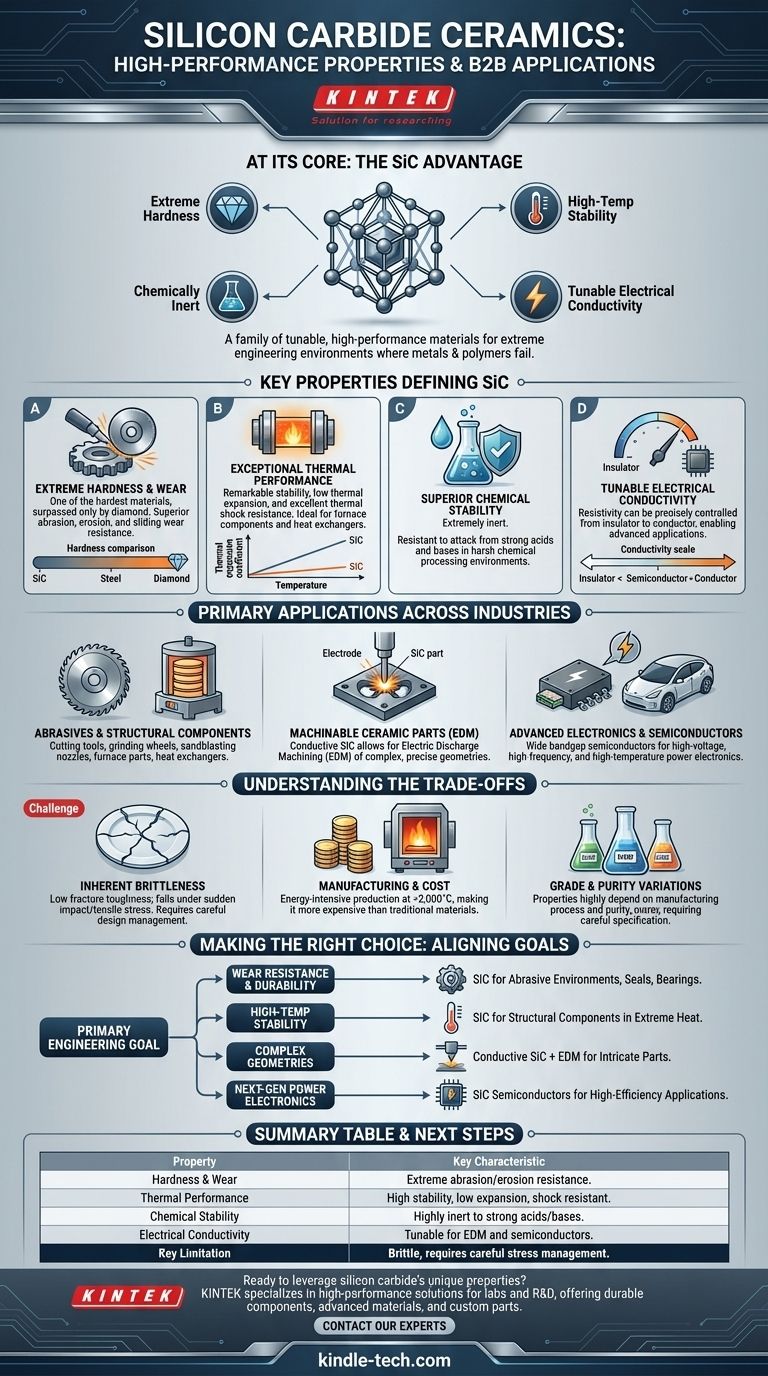

At its core, silicon carbide (SiC) is a high-performance ceramic defined by its exceptional hardness, resistance to extreme temperatures, and unique electrical properties. It is not a single material but a family of materials whose characteristics can be tuned, making it a critical problem-solver for applications where conventional metals and polymers fail.

Silicon carbide's value lies in its combination of seemingly contradictory traits. It is simultaneously wear-resistant, thermally stable, chemically inert, and can be engineered to be either an electrical insulator or a conductor, opening a uniquely broad range of advanced industrial applications.

Key Properties That Define Silicon Carbide

To understand where SiC excels, you must first understand its fundamental material characteristics. These properties are the reason it is selected for some of the most demanding engineering environments.

Extreme Hardness and Wear Resistance

Silicon carbide is one of the hardest commercially available materials, surpassed only by materials like diamond. This inherent hardness translates directly into superior resistance to abrasion, erosion, and sliding wear.

Exceptional Thermal Performance

SiC demonstrates remarkable stability at high temperatures. It has a very low thermal expansion coefficient, meaning it does not expand or contract significantly with temperature changes. This, combined with high thermal conductivity, gives it excellent resistance to thermal shock.

Superior Chemical Stability

As noted in technical literature, SiC is extremely inert and resistant to chemical attack. It does not react with strong acids or bases, making it suitable for use in harsh chemical processing environments.

Tunable Electrical Conductivity

Unlike most ceramics, which are insulators, the electrical resistivity of SiC can be precisely controlled. By adjusting its formulation, it can be made into an excellent insulator, a semiconductor, or a conductor with resistivity below 100 Ω·cm.

Primary Applications Across Industries

The unique combination of these properties makes SiC a versatile material used in a wide array of high-value applications.

Abrasives and Structural Components

Because of its extreme hardness and durability, SiC is a primary material for cutting tools, grinding wheels, and sandblasting nozzles. Its ability to resist deformation at high temperatures also makes it ideal for furnace components, kiln furniture, and heat exchangers.

Machinable Ceramic Parts

The ability to make SiC electrically conductive is a significant manufacturing advantage. This property allows for the use of Electric Discharge Machining (EDM), enabling the precise creation of large or complex-shaped components that would be nearly impossible to form using traditional mechanical methods.

Advanced Electronics and Semiconductors

As a semiconductor, SiC has a wide bandgap and high thermal conductivity. This allows SiC-based devices, like diodes and transistors, to operate at much higher voltages, frequencies, and temperatures than conventional silicon, driving innovation in power electronics and electric vehicles.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of silicon carbide is essential for successful implementation.

Inherent Brittleness

Like most technical ceramics, SiC is hard but also brittle. It has low fracture toughness, meaning it can fail catastrophically under sudden impact or high tensile stress without deforming first. Designs must account for this by managing loads and avoiding sharp corners.

Manufacturing and Cost

Producing high-purity, dense SiC components is an energy-intensive process requiring very high temperatures (often >2,000°C), making it more expensive than traditional metals and polymers. While EDM helps with complex shapes, initial block production remains costly.

Grade and Purity Variations

The properties of a "silicon carbide" part depend heavily on its manufacturing process (e.g., sintered, reaction-bonded, CVD) and purity. These factors significantly influence its thermal conductivity, strength, and electrical properties, requiring careful specification for any given application.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is wear resistance and durability: SiC is a top-tier choice for abrasive environments, seals, and bearings where longevity is critical.

- If your primary focus is high-temperature stability: SiC is the clear solution for structural components that must maintain their strength and shape in extreme heat.

- If your primary focus is creating complex ceramic geometries: Conductive SiC combined with EDM provides a unique pathway for manufacturing intricate, high-performance parts.

- If your primary focus is next-generation power electronics: SiC semiconductors are the industry standard for high-efficiency, high-power applications.

Ultimately, silicon carbide empowers engineers to solve problems in environments too extreme for almost any other material.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Hardness & Wear | Extreme abrasion and erosion resistance, one of the hardest materials available. |

| Thermal Performance | High thermal stability, low thermal expansion, and excellent thermal shock resistance. |

| Chemical Stability | Highly inert and resistant to attack from strong acids and bases. |

| Electrical Conductivity | Tunable from insulator to semiconductor to conductor, enabling EDM machining. |

| Key Limitation | Brittle material with low fracture toughness; requires careful design to manage stress. |

Ready to leverage silicon carbide's unique properties for your project?

KINTEK specializes in high-performance lab equipment and consumables, serving the precise needs of laboratories and R&D facilities. Whether you require durable furnace components, advanced semiconductor materials, or custom ceramic parts, our expertise ensures you get the right solution for extreme environments.

Contact our experts today to discuss how we can support your application with the right materials and equipment.

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

People Also Ask

- What is the temperature resistance of silicon carbide? Withstands Extreme Heat Up to 1500°C

- What are the properties of SiC? Unlock High-Temperature, High-Frequency Performance

- What are the characteristics of SiC? Unlock High-Temp, Hard, and Chemically Inert Performance

- Is silicon carbide heat resistant? Unlock Superior Performance in Extreme Temperatures

- Is silicon carbide better than ceramic? Discover the Superior Technical Ceramic for Your Application