At its core, a molybdenum heating element is not a single product but falls into two distinct categories with vastly different properties. The first category is metallic molybdenum (including pure Mo and its alloys), which excels in vacuum or reducing atmospheres up to around 1700°C. The second is molybdenum disilicide (MoSi2), a ceramic composite designed for high-temperature operation in air, capable of reaching 1800°C.

The most critical factor in choosing a molybdenum heating element is your furnace's atmosphere. Metallic molybdenum is for vacuum or reducing environments, while molybdenum disilicide (MoSi2) is for oxidizing (air) environments. Mismatching the element to the atmosphere will lead to rapid failure.

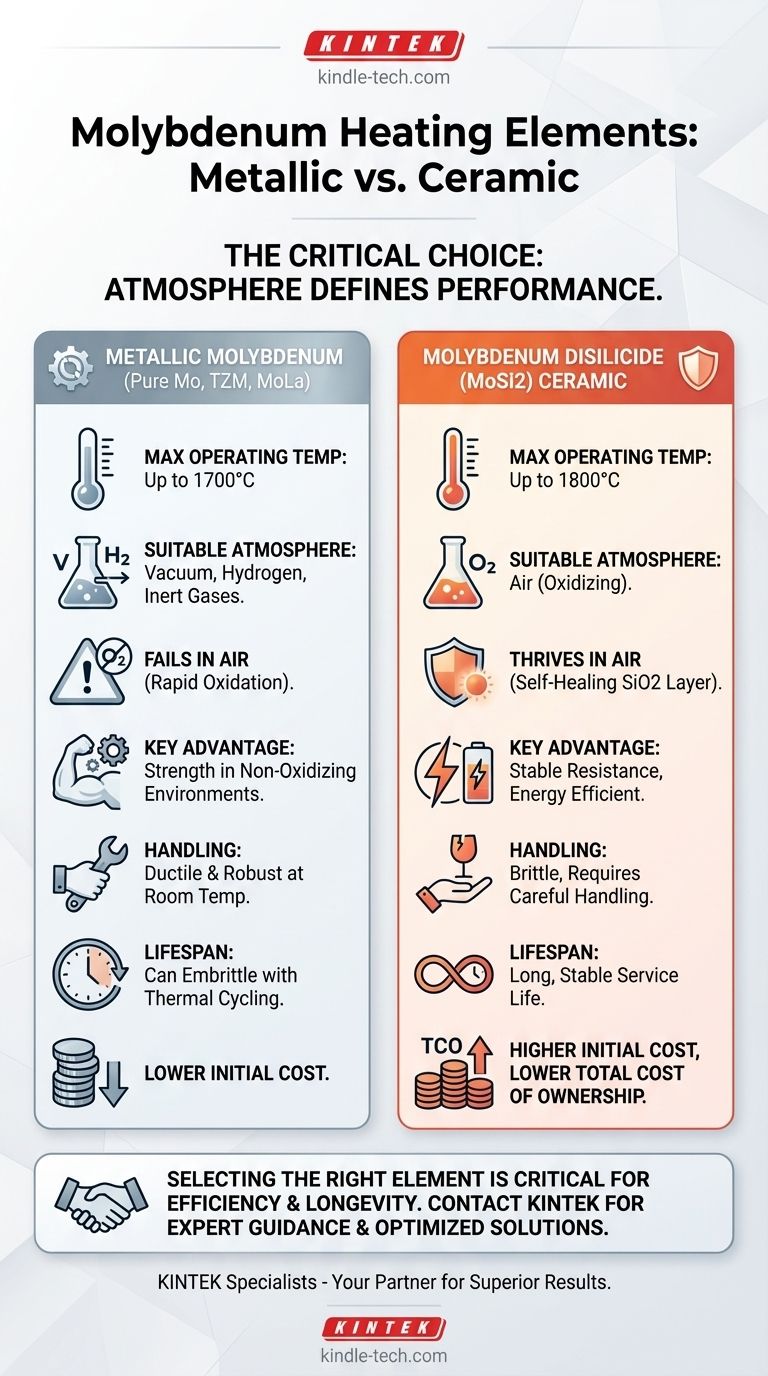

The Two Families of Molybdenum Elements

Understanding the distinction between metallic molybdenum and the ceramic MoSi2 is the key to selecting the correct element for your application. They are fundamentally different materials engineered for different environments.

Metallic Molybdenum Elements (Pure Mo, TZM, MoLa)

Metallic molybdenum is a refractory metal valued for its strength at high temperatures in non-oxidizing environments. Common variants include pure molybdenum, TZM (titanium-zirconium-molybdenum), and MoLa (lanthanum-doped molybdenum).

These elements are the standard for processes like vacuum brazing, annealing, and sintering. Their primary limitation is a severe susceptibility to oxidation, meaning they will rapidly burn up if operated at high temperatures in the presence of air.

While they can tolerate peaks up to 1700°C, continuous operation is often limited to lower temperatures, such as 1200°C, to prevent recrystallization, which can cause embrittlement and reduce service life.

Molybdenum Disilicide (MoSi2) Ceramic Elements

MoSi2 is a cermet, a composite of ceramic and metallic materials. It is not a pure metal. Its standout feature is its ability to operate at very high temperatures (up to 1800°C) directly in an air atmosphere.

This unique capability comes from a self-healing mechanism. At high temperatures, the element forms a protective, non-porous layer of silicon dioxide (SiO2) on its surface. This glassy layer prevents further oxidation of the underlying material.

Because of this property, MoSi2 elements are the preferred choice for applications like dental furnaces, glass production, and laboratory testing that require high heat in an oxidizing environment.

Deep Dive: Key Performance Properties

The choice between these two families comes down to how their specific properties align with your process requirements.

Maximum Operating Temperature

Metallic molybdenum is typically rated for use up to 1700°C (3100°F) in a vacuum. However, it can become brittle and subject to creep (slow deformation) at very high temperatures.

Molybdenum disilicide (MoSi2) elements are classified by their maximum furnace temperature, with "1700-type" and "1800-type" being common, indicating a max operating temperature of 1700°C and 1800°C, respectively.

Atmospheric Resistance

This is the most critical differentiator. Metallic molybdenum requires a vacuum or a reducing atmosphere (like hydrogen or cracked ammonia). It will be destroyed by oxygen at high temperatures.

MoSi2 thrives in an air atmosphere due to the formation of its protective SiO2 layer. It is specifically designed for oxidizing environments.

Electrical and Thermal Characteristics

MoSi2 elements maintain a constant electrical resistance throughout their service life, which simplifies power control system design. They also possess lower resistivity than many alternatives, saving over 10% in power consumption compared to materials like graphite.

This low resistance and high thermal conductivity also allow MoSi2 elements to achieve working temperature from a cold start very quickly, often within a few hours.

Mechanical Stability and Lifespan

Metallic molybdenum can suffer from creep at temperatures approaching 2000°C and can become brittle after thermal cycling, requiring careful support design within the furnace.

MoSi2 has a very small coefficient of thermal expansion, making it highly resistant to deformation and thermal shock at high temperatures. This, combined with its oxidation resistance, gives it a very long and stable service life.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the trade-offs is essential for reliable furnace design and operation.

Cost vs. Total Cost of Ownership

Molybdenum disilicide elements have a higher initial purchase price compared to metallic molybdenum elements.

However, their long service life, energy efficiency, and ability to be replaced without a full furnace shutdown can result in a lower total cost of ownership in the right application.

Brittleness and Handling

As a ceramic material, MoSi2 is very brittle at room temperature. The elements must be handled with extreme care during shipping and installation to avoid fracture. Metallic molybdenum, by contrast, is far more ductile and robust before its first high-temperature firing.

Atmospheric Mismatches

The consequences of using the wrong element in the wrong atmosphere cannot be overstated. Using a metallic molybdenum element in an air furnace will lead to its immediate and catastrophic failure. While MoSi2 can function in some other atmospheres, its primary advantages are lost, and it may not be the most cost-effective choice.

Making the Right Choice for Your Goal

Your furnace's operating environment is the definitive guide for your selection.

- If your primary focus is high-temperature processes in a vacuum or reducing atmosphere: Metallic molybdenum (Pure Mo or its alloys like TZM) provides the best balance of performance and cost.

- If your primary focus is high-temperature operation in an air atmosphere: Molybdenum disilicide (MoSi2) is the only suitable choice and offers exceptional stability and longevity.

- If your primary focus is long-term stability and energy efficiency in air: MoSi2's stable resistance and lower power consumption make it the superior long-term investment despite a higher initial cost.

Ultimately, selecting the right molybdenum element begins with a clear understanding of your process atmosphere and temperature.

Summary Table:

| Property | Metallic Molybdenum (Pure Mo, TZM, MoLa) | Molybdenum Disilicide (MoSi2) |

|---|---|---|

| Max Operating Temperature | Up to 1700°C (in vacuum/reducing) | Up to 1800°C (in air) |

| Suitable Atmosphere | Vacuum, Hydrogen, Inert Gases | Air (Oxidizing) |

| Key Advantage | Strength in non-oxidizing environments | Self-healing SiO2 layer for oxidation resistance |

| Lifespan Consideration | Can embrittle with thermal cycling | Long, stable service life in air |

| Handling | Ductile and robust at room temperature | Brittle; requires careful handling |

Selecting the right heating element is critical for your process efficiency and equipment longevity. KINTEK specializes in lab equipment and consumables, providing expert guidance and high-performance molybdenum heating elements tailored to your specific furnace atmosphere and temperature requirements.

Let our specialists help you optimize your setup for superior results and lower total cost of ownership.

Contact KINTEK today for a personalized consultation to ensure you choose the perfect element for your application.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- How does electric resistance heat work? Harnessing Direct Energy Conversion for Precise Heating

- Which is better quartz or ceramic heaters? The ultimate guide to spot vs. space heating.

- What causes heating element failure? Prevent Downtime by Understanding the Degradation Process

- Is tungsten brittle at high temperature? Unlocking Its Extreme Heat Performance

- Why is tungsten used in furnaces? Unmatched Heat Resistance for Extreme Temperatures

- At what temperature does molybdenum evaporate? Understanding Its High-Temperature Limits

- How do coaxial heating coils in a TDS system determine hydrogen trap activation energy? Precise Thermal Control Guide