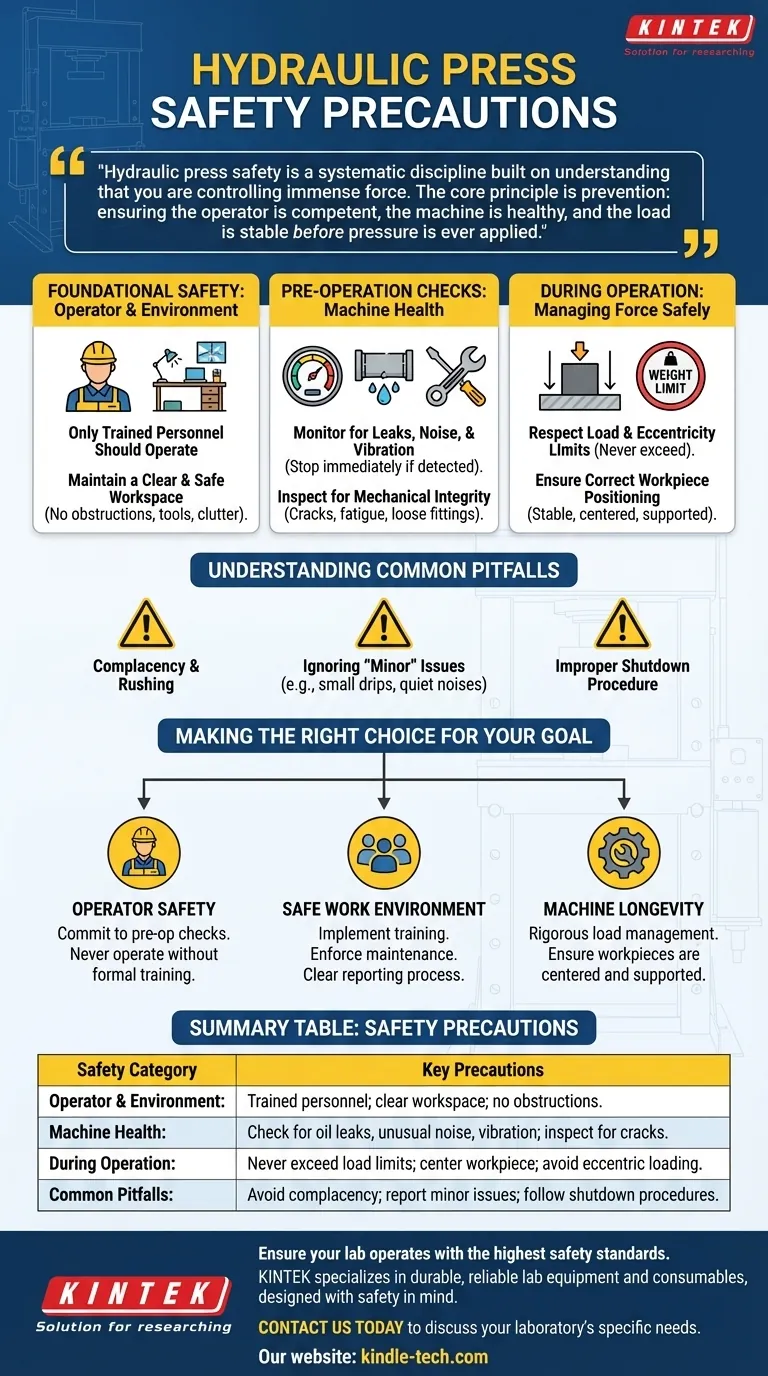

The essential safety precautions for a hydraulic press center on three areas: the operator, the machine's condition, and the work environment. Only trained personnel should operate the press, the workspace must be kept clear, and the machine must be stopped immediately if any issues like oil leaks, unusual noise, or excessive vibration are detected. Critically, the workpiece must be positioned correctly and you must never exceed the machine's load limits.

Hydraulic press safety transcends a simple checklist. It is a systematic discipline built on understanding that you are controlling immense force. The core principle is prevention: ensuring the operator is competent, the machine is healthy, and the load is stable before pressure is ever applied.

Foundational Safety: The Operator and Environment

Before you even approach the machine, safety begins with the person operating it and the space it occupies. These are non-negotiable fundamentals.

Only Trained Personnel Should Operate

A hydraulic press is not an intuitive tool. Authorized operators must be trained on the specific model's capabilities, limitations, and emergency shutdown procedures.

This training ensures the user can recognize signs of improper loading, hydraulic failure, or mechanical stress before they lead to a catastrophic incident.

Maintain a Clear and Safe Workspace

The area around a hydraulic press must be kept completely clear of obstructions, tools, and clutter.

This provides a safe zone for the operator, prevents tripping hazards, and ensures no stray objects are accidentally drawn into the press. A clear area also allows for a quick retreat if a failure occurs.

Pre-Operation Checks and Machine Health

A machine that is not in proper working order is a significant hazard. These checks are your first line of defense against mechanical failure.

Monitor for Leaks, Noise, and Vibration

Before and during use, be vigilant. A serious oil leak indicates a loss of hydraulic integrity and pressure. Loud or unusual noises can signal internal mechanical strain. Excessive vibration points to an unstable load or machine imbalance.

If any of these signs appear, stop the press immediately. The issue must be diagnosed and resolved by qualified personnel before operation resumes.

Inspect for Mechanical Integrity

Visually inspect the press frame, bed, and slider for any signs of cracks, fatigue, or loose fittings.

The immense forces involved can exploit any structural weakness. A seemingly minor crack can lead to a catastrophic failure under load.

During Operation: Managing Force Safely

When the press is active, your focus must be on how the force is being applied. Improper loading is a primary cause of accidents and equipment damage.

Respect Load and Eccentricity Limits

Every press has a maximum tonnage limit that must never be exceeded. Just as important is the limit of eccentricity, which refers to off-center loading.

Placing a workpiece off-center concentrates the entire force on one portion of the frame, creating dangerous torsional stress that the press was not designed to handle.

Ensure Correct Workpiece Positioning

The workpiece must be stable and properly centered on the press bed. Use appropriate blocks and supports to ensure it will not shift, tilt, or slip as pressure is applied.

An unstable workpiece can be ejected from the press at high velocity, posing a severe danger to anyone in the vicinity.

Understanding the Common Pitfalls

Recognizing common mistakes is as important as knowing the correct procedures. Awareness of these traps helps maintain a disciplined approach to safety.

Complacency and Rushing

The most significant risk factor is human error, often born from complacency. Experienced operators may be tempted to skip steps to save time. This is when accidents happen.

Always follow the established safety procedures, for every task, without exception.

Ignoring "Minor" Issues

A small hydraulic drip, a new but quiet noise, or a slight vibration can seem minor. However, these are often the first warnings of a developing failure.

Ignoring these signs is a critical mistake. Document and report any change in the machine's behavior immediately.

Improper Shutdown Procedure

After use, the pressure should be released and the slider should be moved to its lowest position.

This removes stored energy from the hydraulic system and prevents the ram from dropping unexpectedly, ensuring the machine is left in a safe, neutral state.

Making the Right Choice for Your Goal

Your approach to safety should align with your specific responsibilities and goals.

- If your primary focus is personal safety as an operator: Commit to performing pre-operation checks every single time and never working on a machine you have not been formally trained on.

- If your primary focus is managing a safe work environment: Implement and enforce a mandatory training program, a regular maintenance schedule, and a clear, unambiguous reporting process for any machine issues.

- If your primary focus is machine longevity and efficiency: Pay rigorous attention to load management, always ensuring workpieces are centered and supported to avoid putting undue stress on the press frame and components.

A well-maintained press operated with discipline is a powerful tool; a neglected one is a significant liability.

Summary Table:

| Safety Category | Key Precautions |

|---|---|

| Operator & Environment | Only trained personnel; clear workspace; no obstructions |

| Machine Health | Check for oil leaks, unusual noise, vibration; inspect for cracks |

| During Operation | Never exceed load limits; center workpiece; avoid eccentric loading |

| Common Pitfalls | Avoid complacency; report minor issues; follow shutdown procedures |

Ensure your lab operates with the highest safety standards. Properly maintained equipment is the foundation of a secure and efficient workspace. KINTEK specializes in durable, reliable lab equipment and consumables, designed with safety in mind to protect your personnel and your investments. Contact us today (#ContactForm) to discuss how our hydraulic presses and safety solutions can meet your laboratory's specific needs.

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Lab Heat Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- How filter cake increases the efficiency of filtration? It's the True Filtering Medium

- How do laboratory hydraulic presses facilitate biomass pelletization? Optimize Biofuel Density and Prevent Slagging

- How do you use a hydraulic press step by step? A Guide to Safe and Effective Operation

- What is the alternative to KBr in IR spectroscopy? Explore Faster, Easier Sample Prep Methods

- What is the principle of mechanical forging press? Harnessing Kinetic Energy for High-Volume Forging

- How is a sample prepared for XRF analysis? Master the Steps for Accurate Results

- Can a hydraulic press shatter a diamond? Yes, and here's why hardness isn't toughness.

- What affects the speed of a hydraulic motor? Master the balance of flow rate and displacement