The primary standard that defines test sieves in the United States is ASTM E11, "Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves." This specification dictates the precise manufacturing and dimensional requirements for sieves to ensure they provide accurate and repeatable particle size analysis. Sieves that conform to this standard are considered "standard test sieves."

The term "standard test sieve" refers not to a specific list of sizes, but to any sieve that meets the rigorous manufacturing and measurement criteria of a governing specification like ASTM E11. This ensures that results from one lab are comparable to another, forming the foundation of reliable particle size analysis.

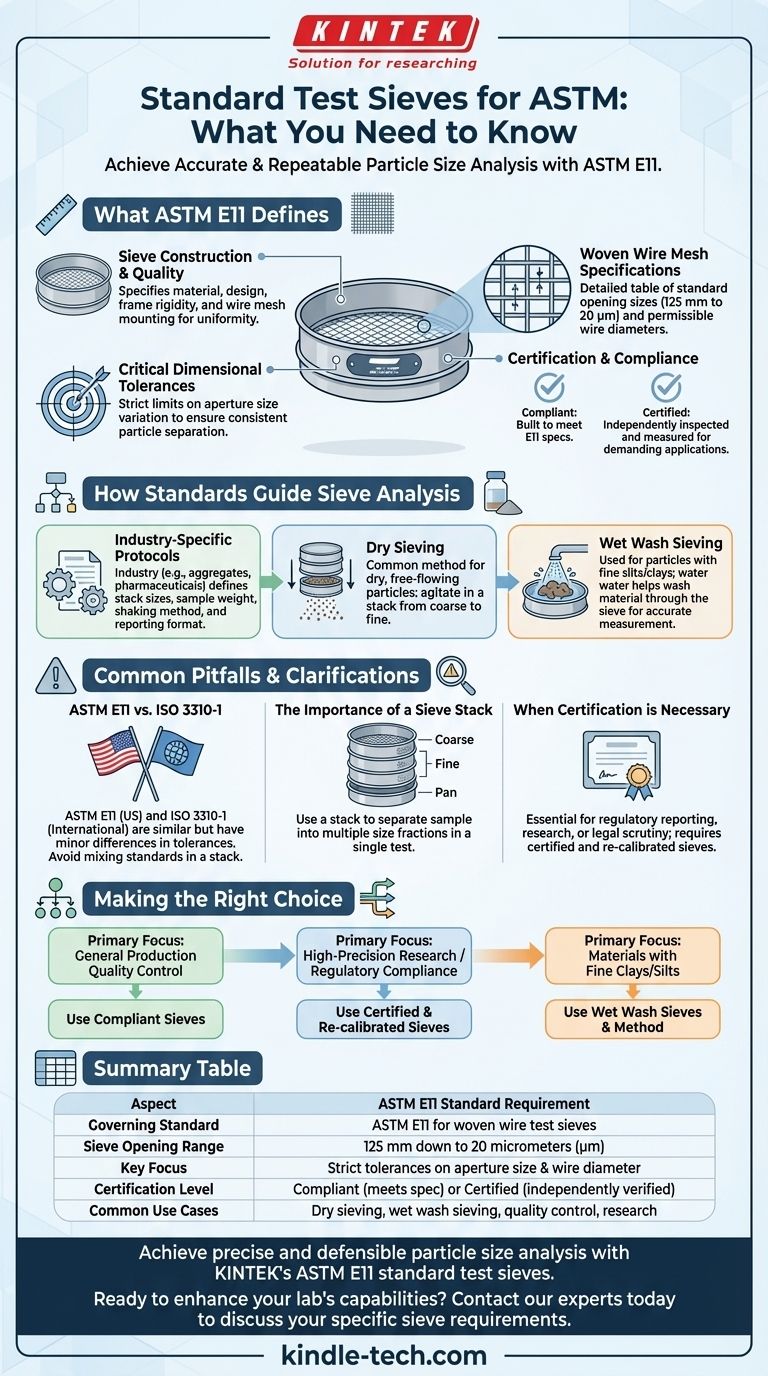

What Does the ASTM E11 Standard Define?

ASTM E11 is a comprehensive document that governs the physical characteristics of a test sieve. Its purpose is to create a universally accepted tool for measurement, much like a calibrated ruler.

Sieve Construction and Quality

The standard specifies the materials, design, and overall build quality of the sieve. This includes the rigidity of the frame and the method used to mount the wire mesh to ensure it remains taut and uniform.

Woven Wire Mesh Specifications

This is the core of the standard. It provides a detailed table of standard sieve opening sizes, ranging from 125 mm down to 20 micrometers (µm). For each opening size, it dictates the permissible range of wire diameters that can be used.

Critical Dimensional Tolerances

A sieve is useless if its openings are not consistent. ASTM E11 sets strict tolerances on the allowable variation in aperture size across the mesh. This is the most critical factor for ensuring accurate and repeatable particle separation.

Certification and Compliance

A sieve can be compliant, meaning the manufacturer built it to meet E11 specifications. For more demanding applications, a sieve can be certified, which means it has been independently inspected and measured to prove it meets the tolerances defined in the standard.

How Standards Guide Sieve Analysis

The ASTM E11 standard for sieve construction is only one piece of the puzzle. Other industry-specific standards dictate how those sieves must be used to produce a valid test result.

Following Industry-Specific Protocols

Your specific industry (e.g., aggregates, pharmaceuticals, food production) will have its own standard methods. These protocols dictate the required sieve sizes for a "stack," the starting sample weight, the duration and method of shaking, and the final reporting format.

Dry Sieving

This is the most common method, used for particles that are dry and free-flowing. The sample is placed in the top sieve of a stack and agitated, typically with a mechanical sieve shaker, allowing particles to fall through successively finer meshes.

Wet Wash Sieving

This technique is required when particles are clumped together or contain fine silts and clays that adhere to larger particles. Water is introduced to help wash the fine material through the sieve, ensuring an accurate measurement of the base particles, which is common in the aggregate and soil industries.

Common Pitfalls and Clarifications

Navigating standards can be confusing. Understanding these key distinctions is crucial for selecting and using the right equipment for your application.

ASTM E11 vs. ISO 3310-1

ASTM E11 is the dominant standard in the United States. The international equivalent is ISO 3310-1. While they are very similar and often considered interchangeable, their specified tolerances and standard opening sizes can have minor differences. Using sieves from both standards in the same stack is not recommended.

The Importance of a Sieve Stack

Particle analysis is rarely done with a single sieve. A "stack" or "nest" of sieves is arranged from the coarsest mesh on top to the finest on the bottom, with a solid pan at the base. This allows for the separation of a sample into multiple size fractions in a single test.

When Certification is Necessary

For routine internal quality control, compliant sieves are often sufficient. However, for regulatory reporting, formal research, or situations where results may be subject to legal scrutiny, using certified and re-calibrated sieves is essential to prove the integrity of your measurements.

Making the Right Choice for Your Analysis

Your specific goal determines the level of compliance and certification you need.

- If your primary focus is general production quality control: Using a stack of sieves that are manufactured to be compliant with ASTM E11 is typically sufficient.

- If your primary focus is high-precision research or regulatory compliance: You must use ASTM E11 certified sieves and have a program for periodic re-certification.

- If your primary focus is analyzing materials with fine clays or silts: You must use wet wash sieves and follow the appropriate wet sieving test method for your industry.

Understanding the role of standards is the first step toward achieving confident and defensible particle size analysis.

Summary Table:

| Aspect | ASTM E11 Standard Requirement |

|---|---|

| Governing Standard | ASTM E11 for woven wire test sieves |

| Sieve Opening Range | 125 mm down to 20 micrometers (µm) |

| Key Focus | Strict tolerances on aperture size and wire diameter |

| Certification Level | Compliant (meets spec) or Certified (independently verified) |

| Common Use Cases | Dry sieving, wet wash sieving, quality control, research |

Achieve precise and defensible particle size analysis with KINTEK's ASTM E11 standard test sieves.

As your trusted lab equipment partner, KINTEK specializes in high-quality sieves and consumables that ensure compliance and accuracy for industries like pharmaceuticals, aggregates, and food production. Our certified sieves are designed for reliable results, whether you're conducting routine quality checks or critical regulatory testing.

Ready to enhance your lab's capabilities? Contact our experts today to discuss your specific sieve requirements and discover the right solution for your particle analysis needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What are advantages and disadvantages of sieving method? A Guide to Reliable & Cost-Effective Particle Sizing

- How do you use a sieve shaker? Master Particle Size Analysis for Quality Control

- What are the apparatus used for sieve analysis? Build a Reliable Particle Sizing System

- What range of particle size does the sieve analysis apply? Master the 25 Micron to 1 mm Standard

- What are the advantages of the sieve method? Achieve Fast, Reliable Particle Size Analysis