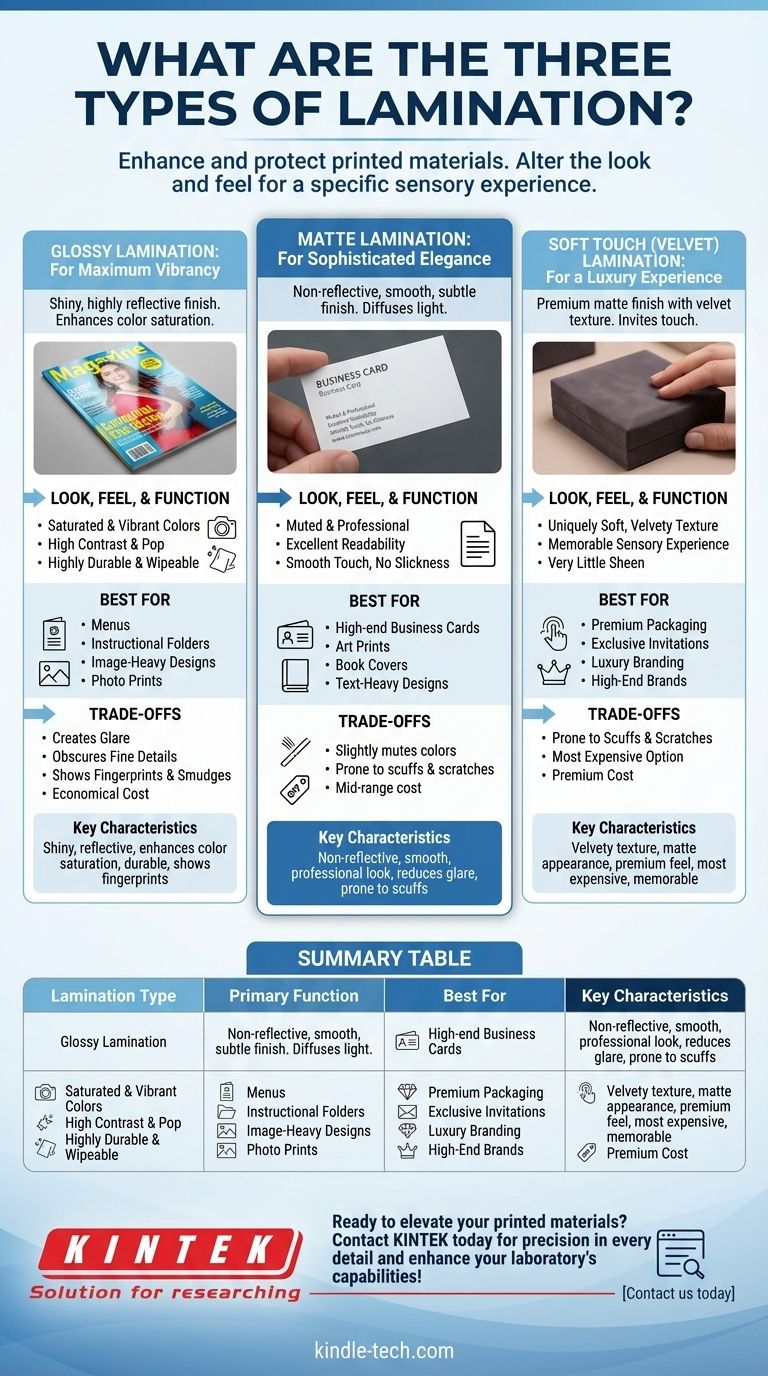

In the world of professional printing, there are three primary types of lamination used to enhance and protect materials: glossy, matte, and soft touch. While all three add a layer of plastic film to paper or cardstock for durability, their true purpose is to fundamentally alter the look and feel of the final product, turning a simple print into a specific sensory experience.

Choosing a lamination is not merely a technical step; it is a critical design decision. The finish you select—whether for vibrancy, elegance, or luxury—directly influences how your audience perceives your brand and message.

Understanding Each Finish: Look, Feel, and Function

Each lamination type serves a distinct purpose, creating a different aesthetic and tactile outcome. The choice depends entirely on the goal of your printed piece.

Glossy Lamination: For Maximum Vibrancy

Glossy lamination provides a shiny, highly reflective finish. Think of the surface of a high-quality photograph or a magazine cover.

This finish makes colors appear more saturated and vibrant. The high contrast it creates is excellent for image-heavy designs, making graphics and photos "pop."

It's also highly durable and can be easily wiped clean, making it a practical choice for items that will be handled frequently, such as menus or instructional folders.

Matte Lamination: For Sophisticated Elegance

Matte lamination offers a non-reflective, smooth, and subtle finish. It diffuses light rather than reflecting it, providing a more muted and professional look.

This lack of glare makes matte an excellent choice for text-heavy designs, as it enhances readability. It feels smooth to the touch but lacks the slickness of a gloss finish.

Matte is often used for high-end business cards, art prints, and book covers where a sense of modern elegance and sophistication is desired.

Soft Touch (Velvet) Lamination: For a Luxury Experience

Soft touch, often called velvet lamination, is a premium finish that prioritizes tactile sensation. Visually, it is a matte finish with very little sheen.

Its defining characteristic is its feel: a uniquely soft, velvety texture that invites touch. This finish is designed to create a memorable, high-end sensory experience.

Because it is focused on creating an impression of luxury and quality, soft touch is the go-to choice for premium packaging, exclusive invitations, and business cards for high-end brands.

Understanding the Trade-offs

No single finish is perfect for every application. Understanding their respective drawbacks is key to making an informed decision.

The Impact on Color and Detail

Glossy lamination enhances color but can create so much glare that it sometimes obscures fine details under direct light.

Matte lamination, while eliminating glare, can slightly mute or soften colors, making them appear less saturated than on the original uncoated print.

Durability vs. Imperfections

The reflective surface of glossy lamination makes it highly susceptible to showing fingerprints and smudges, requiring frequent cleaning to maintain its appearance.

Matte and soft touch finishes are far more resistant to fingerprints. However, they can be more prone to showing scuffs or scratches, which can be particularly noticeable on dark, solid-colored backgrounds.

The Cost Factor

There is a clear cost hierarchy among the three types. Glossy lamination is typically the most economical option.

Matte lamination is a mid-range choice, costing slightly more than gloss. Soft touch is a premium finish and is the most expensive of the three, reflecting its luxury status.

Choosing the Right Lamination for Your Project

Selecting the correct finish requires aligning your choice with the primary goal of your printed material.

- If your primary focus is vibrant color and high impact: Choose glossy lamination to make photos and bold graphics pop off the page.

- If your primary focus is professional elegance and readability: Choose matte lamination for a clean, modern look that minimizes glare on text-heavy designs.

- If your primary focus is creating a memorable, high-end impression: Choose soft touch lamination to engage the sense of touch and convey premium quality.

Ultimately, the best lamination choice is the one that reinforces the message and purpose of your design.

Summary Table:

| Lamination Type | Primary Function | Best For | Key Characteristics |

|---|---|---|---|

| Glossy | Maximum vibrancy & impact | Menus, photo prints, marketing materials | Shiny, reflective, enhances color saturation, durable, shows fingerprints |

| Matte | Sophisticated elegance & readability | Business cards, book covers, text-heavy documents | Non-reflective, smooth, reduces glare, professional look, prone to scuffs |

| Soft Touch | Luxury tactile experience | Premium packaging, high-end invitations, luxury branding | Velvety texture, matte appearance, premium feel, most expensive, memorable |

Ready to elevate your printed materials with the perfect lamination? The right finish can transform your project from ordinary to extraordinary. At KINTEK, we specialize in providing high-quality lab equipment and consumables that support precision in every detail—whether you're testing material durability or ensuring flawless print finishes. Let our expertise help you achieve outstanding results. Contact us today to discuss your specific needs and discover how KINTEK can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a vacuum hot-pressing furnace preferred for C_fiber/Si3N4 composites? Achieve High Density & Fiber Protection

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use