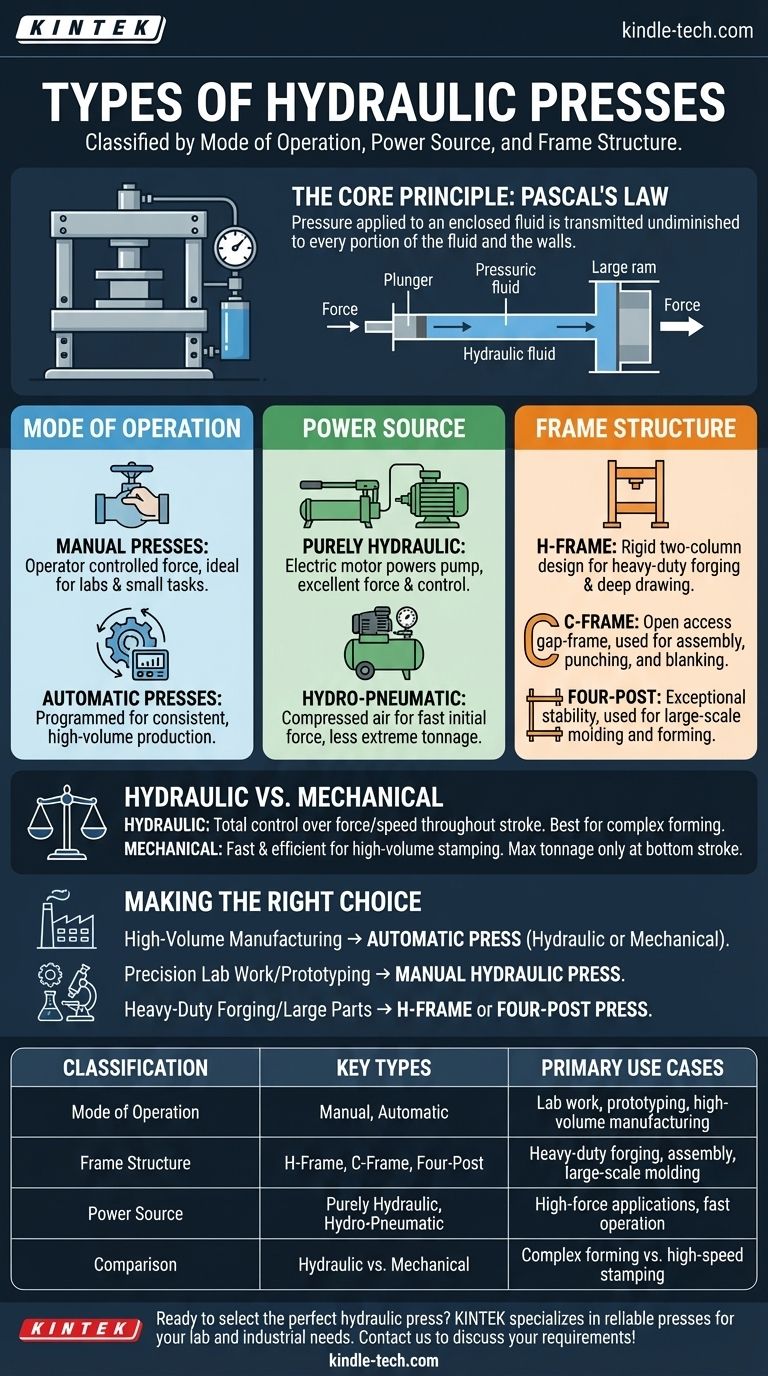

While there is no single official list, hydraulic presses are most usefully classified by their mode of operation, their power source, and their physical frame structure. Operationally, the main types are manual presses, which are ideal for laboratory work and small-scale tasks, and automatic presses, which are programmed for consistent, high-volume industrial production.

The most effective way to understand the "types" of hydraulic presses is not by a simple list, but by how they are built and operated to solve a specific problem—whether it's for industrial-scale forging or for precise laboratory sample preparation.

How a Hydraulic Press Achieves Its Force

The Core Principle: Pascal's Law

At its heart, a hydraulic press operates on a fundamental principle of fluid dynamics known as Pascal's Law. This law states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

A press uses two interconnected cylinders of different sizes, one small (the plunger) and one large (the ram), filled with hydraulic fluid.

When a small force is applied to the plunger, it creates pressure in the fluid. This same pressure acts on the much larger surface area of the ram, generating a proportionally massive output force. This force multiplication is what allows a hydraulic press to crush cars or forge steel with relative ease.

Key Ways to Classify Hydraulic Presses

While presses are used in countless applications, they can be grouped by a few key technical characteristics.

By Mode of Operation

The most immediate distinction is how the operator interacts with the machine.

- Manual Presses: These presses require an operator to control the force, typically with a hand lever or pump. They are common in labs for sample preparation (like XRF pellets), workshops for small assembly jobs, and for tasks requiring fine, real-time control.

- Automatic Presses: These are programmed to execute a specific pressing cycle. An operator can set the desired pressure, speed, and duration, ensuring every cycle is identical. This is essential for high-volume manufacturing, molding, and forming operations where consistency is critical.

By Power Source

The method used to pressurize the hydraulic fluid provides another classification.

- Purely Hydraulic Systems: These use an electric motor to power a pump that pressurizes the hydraulic fluid directly. This is the most common configuration, offering excellent force and control.

- Hydro-Pneumatic Systems: These presses use compressed air to act on the hydraulic fluid. The air pressure provides the initial force on the fluid, which then creates the high-pressure output. They can offer fast operation but may not achieve the extreme forces of purely hydraulic systems.

By Frame Structure

The physical design of the press determines its rigidity and suitability for different tasks. This is a critical, real-world classification.

- H-Frame: This design features a two-column, "H" shaped structure that provides excellent rigidity and strength. It is ideal for heavy-duty forging, deep drawing, and other applications requiring maximum force and minimal frame deflection.

- C-Frame: Also known as a gap-frame press, this design has a "C" shape, offering open access on three sides. This makes it easier to load and unload material but offers less rigidity than an H-frame. It's often used for assembly, punching, and blanking.

- Four-Post: These presses use four cylindrical posts to guide the moving platen, offering exceptional stability and parallelism. They are often used for large-scale molding and forming operations where maintaining a perfectly flat pressing surface is paramount.

Understanding the Trade-offs: Hydraulic vs. Mechanical Presses

Hydraulic presses are often compared to mechanical presses, and the choice between them involves significant trade-offs.

Where Hydraulic Presses Excel

The primary advantage of a hydraulic press is total control over force and speed throughout the entire stroke. The maximum force can be applied at any point, from the top to the bottom of the press cycle. This makes them ideal for complex deep-drawing, molding, and forging operations.

The Mechanical Press Advantage

Mechanical presses operate using a crankshaft and flywheel. They are incredibly fast and efficient for high-volume, repetitive tasks like stamping and blanking. However, they only deliver their maximum tonnage at the very bottom of the stroke, offering less control and flexibility than a hydraulic system.

Making the Right Choice for Your Application

Selecting the correct press type requires matching its characteristics to your primary goal.

- If your primary focus is high-volume, repeatable manufacturing: An automatic press is essential, and you must choose between a fast mechanical press or a more controllable hydraulic press depending on the complexity of the part.

- If your primary focus is precision laboratory work or prototyping: A manual hydraulic press offers the tactile control needed for sample preparation, material testing, and research.

- If your primary focus is heavy-duty forging or forming large parts: An H-frame or four-post hydraulic press provides the necessary structural rigidity and massive, controllable force.

By understanding these core classifications, you can select the precise tool required to achieve your specific engineering or scientific goal.

Summary Table:

| Classification | Key Types | Primary Use Cases |

|---|---|---|

| Mode of Operation | Manual, Automatic | Lab work, prototyping, high-volume manufacturing |

| Frame Structure | H-Frame, C-Frame, Four-Post | Heavy-duty forging, assembly, large-scale molding |

| Power Source | Purely Hydraulic, Hydro-Pneumatic | High-force applications, fast operation |

| Comparison | Hydraulic vs. Mechanical | Complex forming vs. high-speed stamping |

Ready to select the perfect hydraulic press for your needs? KINTEK specializes in lab equipment and consumables, providing reliable hydraulic presses for sample preparation, material testing, and industrial applications. Our experts will help you choose the right press to enhance your lab's efficiency and precision. Contact us today to discuss your requirements!

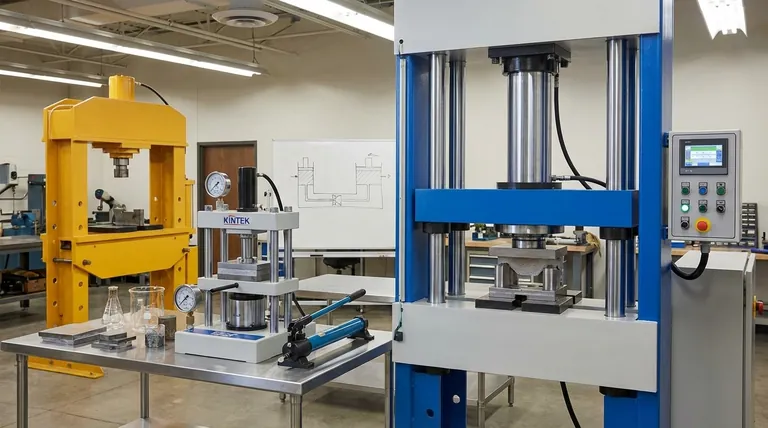

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples