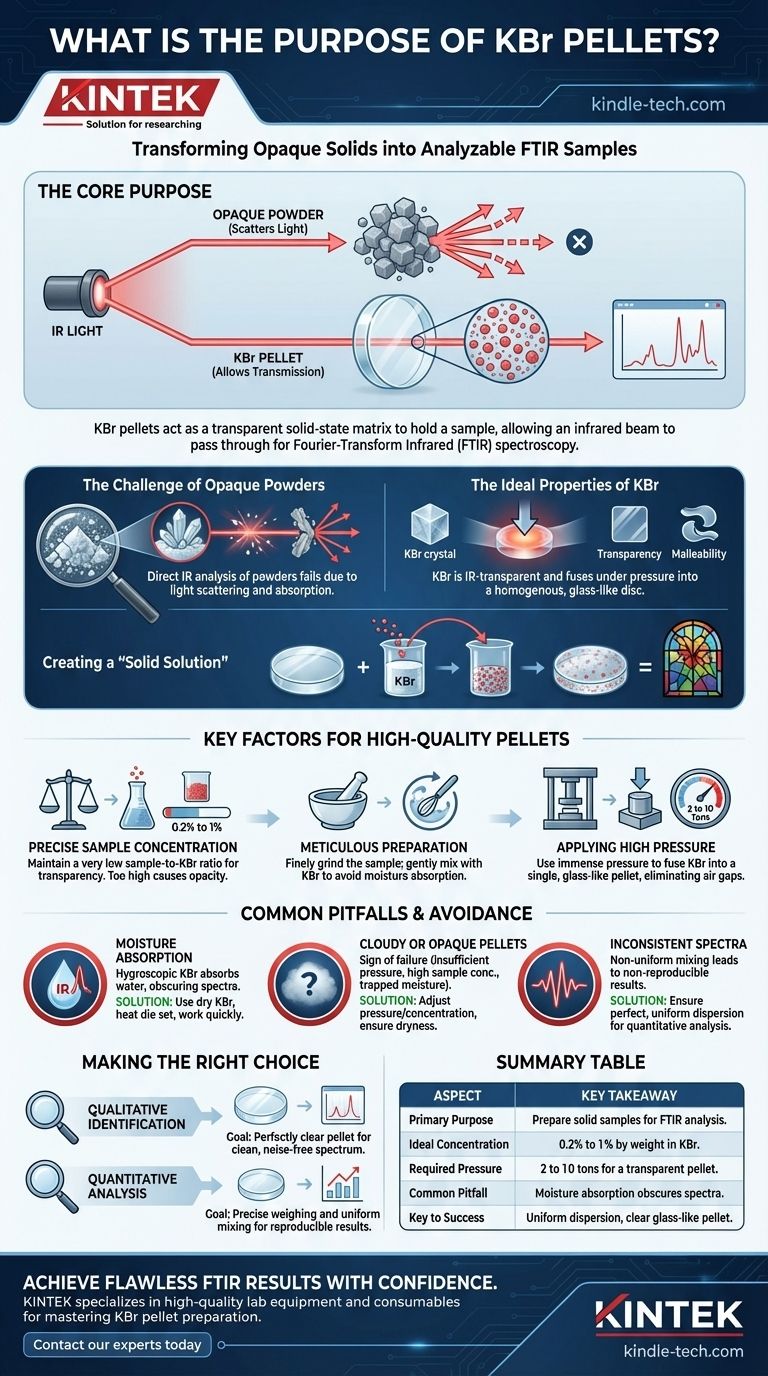

The primary purpose of a KBr pellet is to prepare a solid sample for analysis using Fourier-Transform Infrared (FTIR) spectroscopy. Potassium Bromide (KBr) acts as a solid-state matrix that holds the sample, allowing an infrared beam to pass through it for measurement.

Analyzing solid samples with infrared light is often impossible because opaque powders scatter or block the beam. The KBr pellet method solves this by dispersing the sample powder into an infrared-transparent salt (KBr), which is then pressed into a thin, glass-like disc that the IR beam can analyze effectively.

Why KBr is the Standard for Solid Sample Analysis

Understanding the KBr pellet method begins with the fundamental challenge of analyzing solids with light.

The Challenge of Opaque Powders

Most solid organic and inorganic compounds are crystalline powders in their pure state.

Attempting to pass an IR beam directly through a powder results in the light being scattered in all directions or completely absorbed, producing a noisy and unusable spectrum.

The Ideal Properties of KBr

Potassium Bromide is the chosen material because it is transparent to infrared radiation across the most common analytical range.

It is also a relatively soft salt that, under pressure, flows and fuses into a homogenous, transparent disc, much like glass.

Creating a "Solid Solution"

The goal is to create a uniform, microscopic dispersion of the sample within the KBr matrix.

Think of it like tiny fragments of colored glass (your sample) suspended perfectly within a clear window pane (the KBr). The clear pane allows you to see the color and properties of the fragments without interference.

Key Factors for a High-Quality Pellet

The quality of the final spectrum is entirely dependent on the quality of the KBr pellet. Several factors are critical to success.

Precise Sample Concentration

The concentration of the sample within the KBr must be very low, typically in the range of 0.2% to 1%.

A concentration that is too high will cause the pellet to be opaque, absorbing the IR beam completely or causing excessive scattering. This results in flattened peaks and a useless spectrum.

Meticulous Preparation

The sample itself must be ground into a fine powder to ensure it can be dispersed evenly.

However, the KBr should not be ground extensively, as this increases its surface area and encourages the absorption of moisture from the air. The sample and KBr are mixed gently together.

Applying High Pressure

A die set and a hydraulic press are used to apply immense pressure, typically 2 to 10 tons, to the KBr/sample mixture.

This pressure fuses the individual KBr crystals into a single, transparent, and glass-like pellet, eliminating air gaps that would otherwise scatter the IR beam.

Common Pitfalls and How to Avoid Them

The most common issues with KBr pellets stem from contamination and improper technique. Mastering this method means understanding what can go wrong.

The Problem of Moisture

KBr is hygroscopic, meaning it readily absorbs water from the atmosphere. Water has a very strong and broad absorption signal in the IR spectrum, which can obscure important peaks from your sample.

To avoid this, always use dry KBr, heat the die set before use to drive off any moisture, and prepare the pellet as quickly as possible.

Cloudy or Opaque Pellets

A pellet that appears cloudy or white is a sign of failure. This is typically caused by three things:

- Insufficient pressure, which fails to fuse the KBr crystals.

- Excessive sample concentration, making the pellet inherently opaque.

- Trapped moisture or air bubbles that scatter light.

Inconsistent Spectra

If a sample is not mixed uniformly into the KBr powder, some parts of the pellet will have a higher concentration than others. This leads to non-reproducible spectra and makes quantitative analysis impossible.

Making the Right Choice for Your Goal

Achieving a reliable spectrum requires tailoring your technique to your analytical objective.

- If your primary focus is qualitative identification: Your goal is a perfectly clear, transparent pellet to produce a clean, noise-free spectrum with sharp, well-defined peaks.

- If your primary focus is quantitative analysis: You must prioritize precise weighing of the sample and KBr and ensure perfectly uniform mixing to achieve reproducible results.

- If you are troubleshooting a poor spectrum: First, check for the broad, distinctive peaks of water contamination, then inspect the pellet visually for cloudiness that indicates light scattering.

Mastering the KBr pellet technique is a fundamental skill that transforms opaque solids into analyzable samples, unlocking clear and reliable spectroscopic data.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Purpose | Prepare solid samples for FTIR spectroscopy analysis. |

| Ideal Sample Concentration | 0.2% to 1% by weight in KBr. |

| Required Pressure | 2 to 10 tons for a transparent pellet. |

| Common Pitfall | Moisture absorption, leading to obscured spectra. |

| Key to Success | Uniform dispersion and a perfectly clear, glass-like pellet. |

Achieve flawless FTIR results with confidence. The KBr pellet method is a cornerstone of reliable solid sample analysis. KINTEK specializes in providing the high-quality lab equipment and consumables—including precise hydraulic presses, durable pellet dies, and pure, dry KBr—that your laboratory needs to master this technique.

Eliminate the variables of inconsistent preparation and get the clear, reproducible data you require. Contact our experts today to find the perfect solution for your spectroscopy workflow.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What is the difference between plate and frame filter press? A Guide to Choosing the Right Dewatering Technology

- What is the strength of a hydraulic press? Harnessing Pascal's Principle for Immense Force

- What are the parameters to be considered for selecting the thin wall molding machine? Key Specs for High-Speed Production

- What is the function of a laboratory uniaxial hydraulic press in battery assembly? Unlock High-Performance Cells

- Is pressure constant in a hydraulic press? Unlock the Power of Force Multiplication

- What function does a laboratory hydraulic press serve in boron carbide production? Mastering Green Body Consolidation

- What is the world's strongest hydraulic press? Unpacking the 80,000-Ton vs. 60,000-Ton Giants

- What is the cost of XRF per sample? Find the Right Price for Your Accuracy Needs