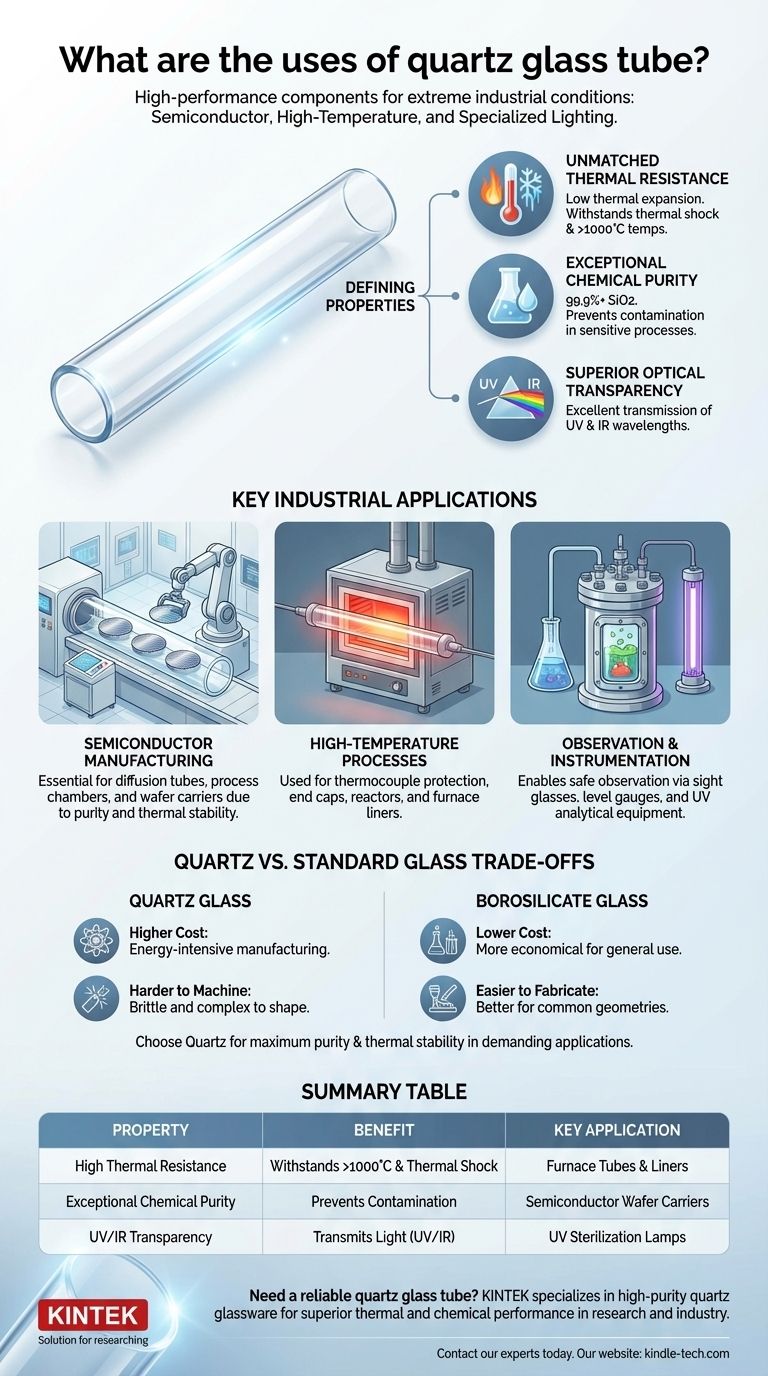

In technical applications, a quartz glass tube is not simply a piece of glass; it is a high-performance component chosen for its unique ability to withstand extreme conditions. Its primary uses are found in demanding industrial processes, such as semiconductor manufacturing, high-temperature furnace applications, and specialized lighting, where its combination of thermal stability, chemical purity, and optical transparency is non-negotiable.

The decision to use a quartz glass tube is almost always driven by a need for material properties that conventional glass cannot provide. Its value lies in its extreme purity and its resistance to high temperatures and thermal shock.

The Defining Properties of Quartz Glass

To understand the applications of quartz tubes, we must first understand the material itself. Unlike standard glass, quartz glass is composed of nearly pure silicon dioxide (SiO2), giving it a unique set of characteristics that dictate its use.

Unmatched Thermal Resistance

Quartz has an extremely low coefficient of thermal expansion. This allows it to endure rapid temperature changes of hundreds of degrees without cracking—a phenomenon known as thermal shock.

It can also be used continuously at temperatures exceeding 1000°C, making it indispensable for high-temperature furnace components and heat treatment processes.

Exceptional Chemical Purity

Quartz glass is produced by melting natural quartz crystals with a purity of at least 99.9% SiO2. This process results in a material with exceptionally low levels of contaminants.

This high purity is critical in industries like semiconductor manufacturing, where even trace amounts of metallic impurities can ruin sensitive electronic components during production.

Superior Optical Transparency

Quartz offers excellent transmission of light across a wide spectrum, including ultraviolet (UV) and infrared (IR) wavelengths, where normal glass is opaque.

This property makes it the ideal material for UV sterilization lamps, sight glasses for monitoring chemical reactions, and optical components in scientific instruments.

Key Industrial Applications in Detail

The properties of quartz directly translate to its use in highly specialized and critical applications.

Semiconductor Manufacturing

This is one of the largest markets for quartz. Its purity prevents contamination in cleaning baths, and its thermal stability is vital for diffusion tubes and process chambers where silicon wafers are treated at extreme temperatures.

It is used to make transfer carriers, furnace tubes, and boats that hold wafers during chemical vapor deposition (CVD) and etching.

High-Temperature Processes

In industrial and laboratory furnaces, quartz tubes serve as thermocouple protection sheaths, allowing for accurate temperature measurement without degrading.

They are also used as end caps, process reactors, and furnace liners, containing extreme heat and protecting the integrity of the process.

Observation and Instrumentation

Because it remains clear and stable at high temperatures, quartz is used for sight glasses and level gauges on high-pressure boilers and chemical reactors.

This allows operators to safely observe processes that would be impossible to view through standard glass. Its UV transparency also makes it essential for analytical and diagnostic equipment.

Understanding the Trade-offs: Quartz vs. Standard Glass

While its properties are superior, quartz is not always the right choice. Understanding its trade-offs against more common materials like borosilicate glass is key for proper specification.

The Cost Factor

Quartz glass is significantly more expensive than borosilicate glass (the material used in most common lab glassware).

Its manufacturing process—melting highly pure crystalline quartz at very high temperatures—is far more energy-intensive and complex.

Machinability and Fabrication

Quartz is a harder and more brittle material than standard glass, making it more difficult and costly to cut, shape, and form into complex geometries.

This means that for general-purpose applications that do not involve extreme temperatures or require UV transparency, borosilicate glass is often the more practical and economical choice.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary technical objective.

- If your primary focus is maximum purity and thermal stability: Quartz glass is the only choice for applications like semiconductor processing or high-temperature furnace components.

- If your primary focus is visual observation in a high-temperature or corrosive environment: Quartz sight glasses or tubes provide the necessary safety and clarity.

- If your primary focus is general laboratory use without extreme conditions: Borosilicate glass offers excellent chemical resistance and durability at a much lower cost.

Ultimately, choosing quartz is an engineering decision to solve a problem where lesser materials would fail.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| High Thermal Resistance | Withstands temperatures >1000°C & thermal shock | High-temperature furnace tubes & liners |

| Exceptional Chemical Purity | Prevents contamination in sensitive processes | Semiconductor wafer carriers & process chambers |

| UV/IR Transparency | Transmits light where standard glass is opaque | UV sterilization lamps & analytical instrument viewports |

Need a reliable quartz glass tube for your demanding application? KINTEK specializes in high-purity lab equipment and consumables, including quartz glassware designed for superior thermal and chemical performance. Our products ensure process integrity in semiconductor, research, and industrial settings. Contact our experts today to find the perfect solution for your laboratory's specific needs!

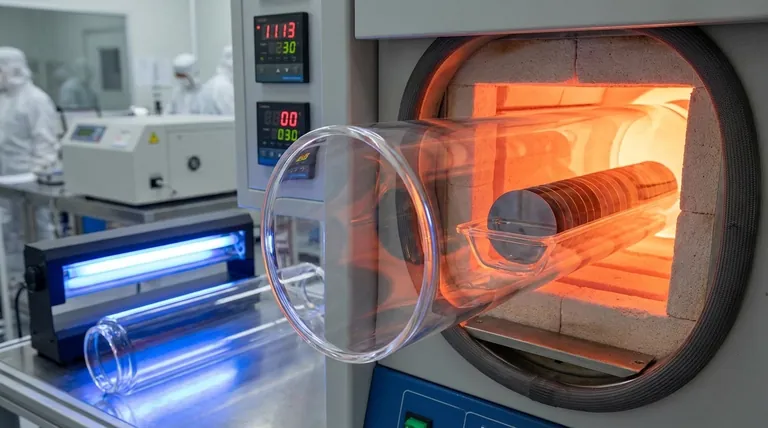

Visual Guide

Related Products

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why does the pressure switch keep tripping on my furnace? Diagnose the Root Cause and Restore Heat

- Why must high-purity quartz tubes be used for aluminum and water vapor reactions? Ensure Purity & Accuracy

- What is the function of a mechanical stirrer in catalyst prep? Ensure Homogeneity in Mixed Oxide Catalyst Supports

- What are the technical advantages of the conical structure design in a quartz reactor? Ensure High-Fidelity WGSR Testing

- How does an adjustable speed stirrer contribute to the chemical dissolution of iridium in leaching equipment?

- What is the role of a magnetic stirrer in silver sulfide rarefaction? Enhance Photocatalytic Efficiency

- What is mold release spray made of? A Guide to Non-Stick Coatings for Molding

- How does a water circulating vacuum pump operate? Discover the Efficient Liquid Piston Principle