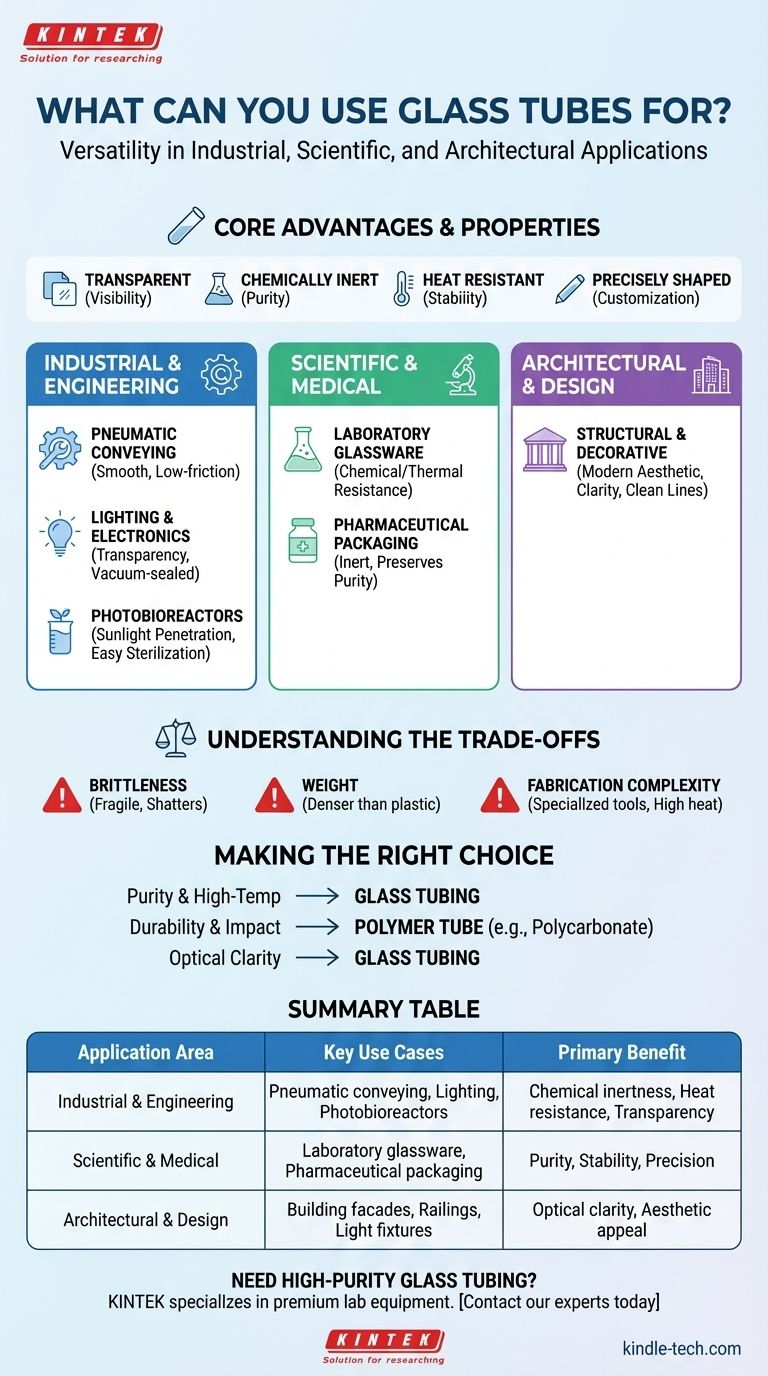

In short, glass tubes are used in a vast range of applications, from industrial systems and scientific laboratories to architectural design. They can be used directly off the shelf for things like lighting or pneumatic conveying systems, or they can be modified for highly specialized purposes like pharmaceutical packaging and laboratory glassware.

The core reason for this versatility is glass's unique combination of properties: it is transparent, chemically inert, resistant to heat, and can be precisely shaped, making it an indispensable material in fields where purity, visibility, and stability are critical.

Industrial and Engineering Applications

Glass tubing is a fundamental component in many industrial processes where its unique material properties provide a distinct advantage over plastics or metals.

Pneumatic Conveying Systems

The smooth, low-friction surface of glass is ideal for pneumatic systems that transport powders, granules, or other small solids. This ensures materials flow efficiently without contamination.

Lighting and Electronics

Glass is essential for lighting due to its high transparency and ability to withstand the heat generated by filaments or LEDs. It is also used to create vacuum-sealed enclosures, such as for encapsulating sensitive electronic components like diodes.

Photobioreactors

For cultivating microorganisms like algae, photobioreactors made of glass tubing are highly effective. The glass allows maximum sunlight penetration for photosynthesis while being easy to sterilize and chemically non-reactive with the growth medium.

Scientific and Medical Uses

In environments that demand absolute purity and precision, glass is often the only suitable material. Its stability ensures that experiments and medical products are not compromised.

Laboratory Glassware

The ubiquitous test tube is the classic example, but glass tubing is the basis for a huge array of lab equipment. Its resistance to chemicals and thermal shock makes it perfect for handling reactive substances and enduring rapid temperature changes.

Pharmaceutical Packaging

Glass is the gold standard for packaging sensitive medicines, such as vaccines. Its inert nature guarantees that it will not leach chemicals into the contents, preserving the drug's purity and efficacy.

Architectural and Design Applications

Beyond its technical uses, the aesthetic quality of glass tubing makes it a popular choice in modern architecture and design.

Structural and Decorative Elements

Designers use glass tubes for everything from creating striking building facades and railings to crafting unique light fixtures. The material's clarity and clean lines offer a modern aesthetic that is both functional and beautiful.

Understanding the Trade-offs

While incredibly useful, glass tubing is not the solution for every problem. Understanding its limitations is key to using it effectively.

Brittleness

The most significant drawback of glass is its fragility. Unlike plastic, it does not bend or deform under stress; it shatters. This makes it unsuitable for high-impact environments without specialized reinforcement.

Weight

Glass is considerably denser and heavier than plastic alternatives. This can be a limiting factor in applications where weight is a primary concern, such as in aerospace or portable equipment.

Fabrication Complexity

While the base material is common, modifying glass tubes requires specialized tools and high heat. This fabrication process is often more complex and costly than molding plastic.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on the non-negotiable requirements of your project.

- If your primary focus is chemical purity and high-temperature stability: Glass tubing is the superior choice, particularly for laboratory or medical applications.

- If your primary focus is durability and impact resistance: A polymer tube, such as polycarbonate or acrylic, is a more practical and safer solution.

- If your primary focus is optical clarity for design or lighting: Glass tubing provides a level of transparency and a premium finish that most plastics cannot match.

Ultimately, the unique properties of glass ensure its role as an essential material across a vast spectrum of modern innovation.

Summary Table:

| Application Area | Key Use Cases | Primary Benefit of Glass |

|---|---|---|

| Industrial & Engineering | Pneumatic conveying, Lighting, Photobioreactors | Chemical inertness, Heat resistance, Transparency |

| Scientific & Medical | Laboratory glassware, Pharmaceutical packaging | Purity, Stability, Precision |

| Architectural & Design | Building facades, Railings, Light fixtures | Optical clarity, Aesthetic appeal |

Need high-purity glass tubing for your laboratory or industrial application?

KINTEK specializes in supplying premium lab equipment and consumables, including durable, chemically inert glass tubes designed for precision and reliability. Whether you're setting up a new photobioreactor or need custom glassware for sensitive pharmaceutical work, our products ensure your processes remain uncontaminated and efficient.

Contact our experts today to find the perfect glass tubing solution for your specific needs!

Visual Guide

Related Products

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

- Boron Nitride (BN) Ceramic Tube

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

People Also Ask

- What are the limitations of the IR spectroscopy? Understanding Its Boundaries for Accurate Analysis

- How does quartz differ from glass? A Guide to Material Selection for Performance

- What does a layered film mean? Unpacking the Depths of Cinematic Storytelling

- What are the five rules of chemical safety? Build a Proactive Culture of Lab Safety

- How does potassium bromide affect humans? A Look at Its Risks and Obsolete Medical Use