At its core, a heating element burns out when a section of its internal wire breaks. This break is most often caused by a combination of intense heat, electrical stress, and gradual material degradation. Factors like corrosion, voltage spikes, and even poor airflow can dramatically accelerate this process, leading to premature failure.

The fundamental reason a heating element fails is that the very process that allows it to create heat—resisting electrical current—also causes it to destroy itself over time. Burnout occurs when a weak point in the element can no longer withstand this constant thermal and electrical stress.

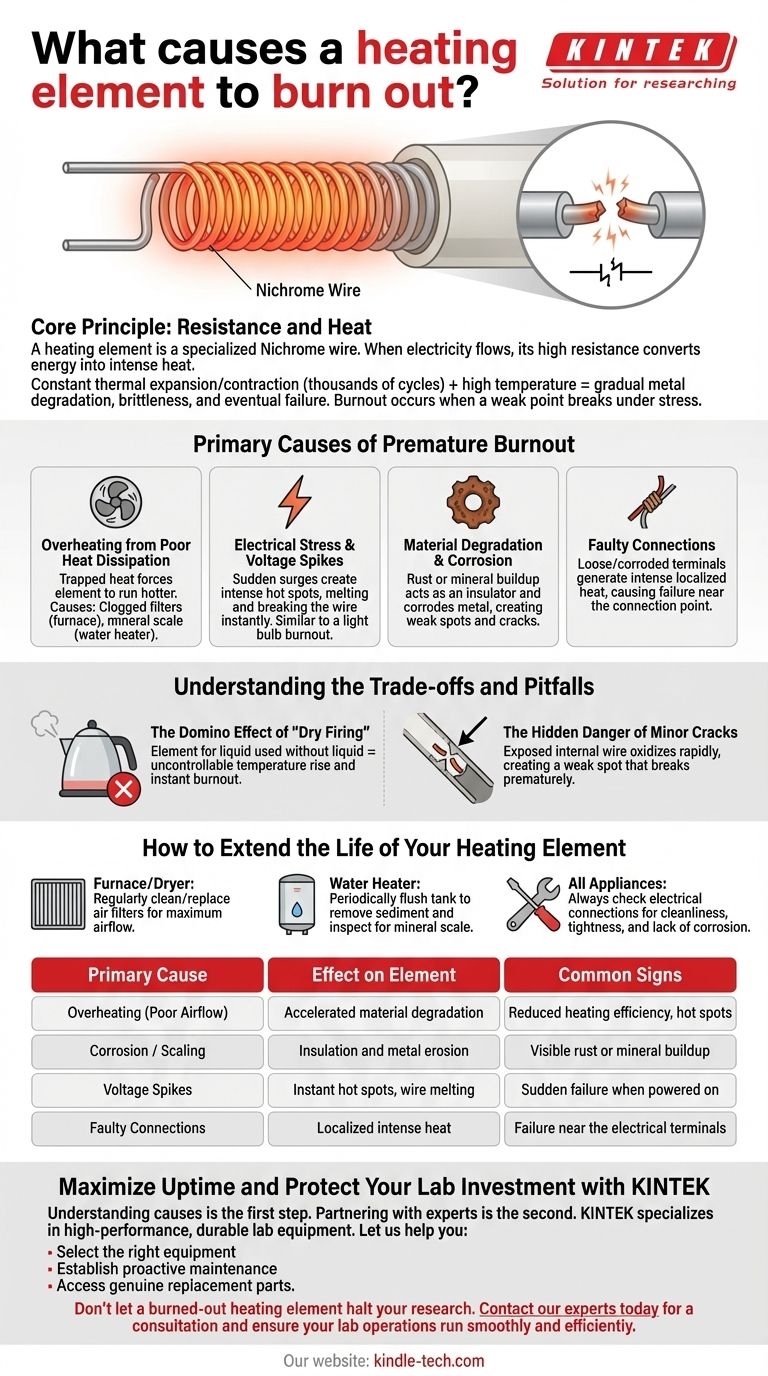

The Core Principle: Resistance and Heat

How an Element Works

A heating element is essentially a specialized wire, typically made of a nickel-chromium alloy called Nichrome, designed to have high electrical resistance.

When electricity is forced through this resistant wire, the energy is converted into intense heat. This process is incredibly effective but puts the wire under constant, extreme stress.

The Inevitable Path to Failure

Every time the element heats up and cools down, the wire expands and contracts. Over thousands of cycles, this thermal stress, combined with the high operating temperature, gradually degrades the metal, making it more brittle and susceptible to failure.

Primary Causes of Premature Burnout

While all elements eventually wear out, certain conditions can drastically shorten their operational lifespan.

Overheating from Poor Heat Dissipation

The single biggest enemy of a heating element is its own heat if it cannot escape. The element is designed to operate at a specific temperature, and anything that traps heat around it forces it to get even hotter, accelerating its degradation.

Common examples include a clogged filter in a furnace restricting airflow or a thick layer of mineral scale insulating a water heater element.

Electrical Stress and Voltage Spikes

A sudden surge in your home's voltage can send a jolt of excessive current through the element. This can create an intense hot spot that instantly melts and breaks the internal wire.

This is similar to how an old incandescent light bulb often burns out the moment you flip the switch.

Material Degradation and Corrosion

The reference you found correctly identifies corrosion as a key culprit. Rust or mineral buildup on the element's surface creates two problems.

First, it acts as an insulator, causing the overheating mentioned above. Second, it can eat into the metal, creating thin spots or cracks that become concentrated hot spots and eventually break the circuit.

Faulty Connections

Loose or corroded electrical connections at the terminals of the heating element create high resistance. This resistance generates intense heat at the connection point, which can travel into the element and cause it to fail near the terminal. This is a common and often misdiagnosed point of failure.

Understanding the Trade-offs and Pitfalls

Recognizing the early signs of these issues is crucial for preventing a complete burnout. What seems like a minor problem is often the direct precursor to failure.

The Domino Effect of "Dry Firing"

"Dry firing" occurs when an element designed for liquid, like in a water heater or kettle, is turned on with no liquid present.

Without water to absorb the immense heat, the element's temperature can rise uncontrollably in seconds, causing it to glow red-hot and burn out almost instantly.

The Hidden Danger of Minor Cracks

A small, visible crack in the element's outer sheath or a spot of corrosion may not seem serious. However, this is a critical failure point.

The internal wire is now exposed to air, allowing it to oxidize rapidly when hot. This creates a weak spot that will inevitably break, often much sooner than expected.

How to Extend the Life of Your Heating Element

You can significantly improve the longevity of your heating elements by controlling the conditions that accelerate their failure.

- If your primary focus is a furnace or dryer: Regularly clean or replace your air filters to ensure maximum airflow, allowing the element to dissipate heat effectively.

- If your primary focus is a water heater: Periodically flush the tank to remove sediment and inspect the element for mineral scale, cleaning or replacing it as needed.

- If you are troubleshooting any appliance: Always check that the electrical connections to the element are clean, tight, and free of corrosion.

By understanding that a heating element's life is a battle against heat and degradation, you can take simple steps to ensure it runs efficiently for as long as possible.

Summary Table:

| Primary Cause | Effect on Element | Common Signs |

|---|---|---|

| Overheating (Poor Airflow) | Accelerated material degradation | Reduced heating efficiency, hot spots |

| Corrosion / Scaling | Insulation and metal erosion | Visible rust or mineral buildup |

| Voltage Spikes | Instant hot spots, wire melting | Sudden failure when powered on |

| Faulty Connections | Localized intense heat | Failure near the electrical terminals |

Maximize Uptime and Protect Your Lab Investment with KINTEK

Understanding the causes of heating element failure is the first step to prevention. The second is partnering with an expert who can provide durable, reliable equipment and support.

At KINTEK, we specialize in high-performance lab equipment and consumables designed for longevity. Our heating elements are engineered with robust materials and precise manufacturing to withstand the thermal and electrical stresses of daily laboratory use.

Let us help you:

- Select the right equipment for your specific application to avoid premature wear.

- Establish a proactive maintenance schedule to catch issues before they lead to costly downtime.

- Access genuine replacement parts that guarantee compatibility and performance.

Don't let a burned-out heating element halt your research. Contact our experts today for a consultation and ensure your lab operations run smoothly and efficiently.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Which high temperature furnace elements to be used in oxidizing atmosphere? MoSi2 or SiC for Superior Performance

- What material is used for furnace heating? Select the Right Element for Your Process

- What are the heating elements for high temperature furnaces? Select the Right Element for Your Atmosphere

- Is molybdenum disulfide a heating element? Discover the best material for high-temperature applications.

- What is the thermal expansion coefficient of molybdenum disilicide? Understanding its role in high-temperature design