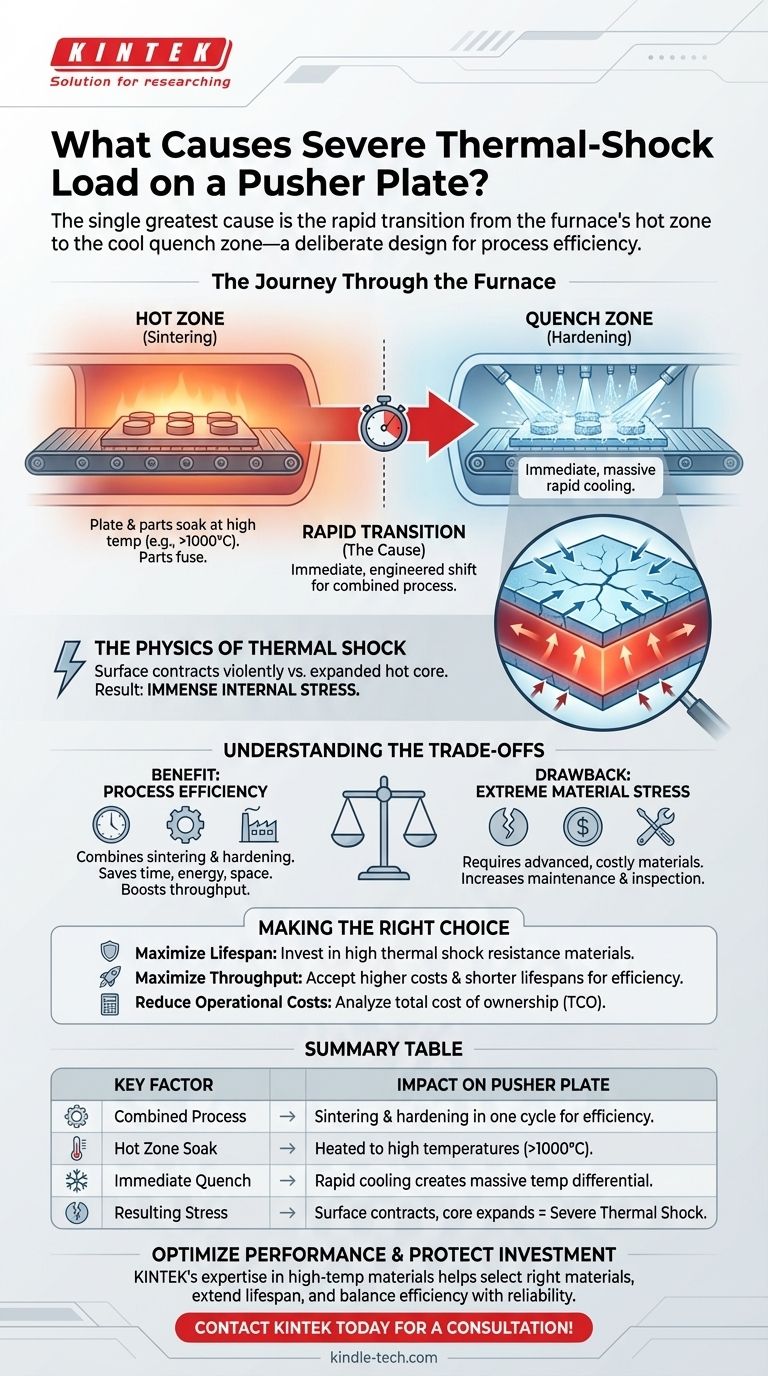

The single greatest cause of severe thermal-shock load on a pusher plate is its rapid transition from the furnace's high-temperature "hot zone" directly into a much cooler "quench zone." This is not an accident but a deliberate design choice in many modern manufacturing lines. The process is engineered to combine sintering with surface hardening in a single, efficient run, but this efficiency forces the pusher plate to endure an extreme and sudden drop in temperature.

The core issue is a trade-off: manufacturers achieve significant process efficiency by combining sintering and hardening, but this subjects the pusher plate to one of the most severe thermal shock conditions found in industry, creating a major material engineering challenge.

The Journey Through the Furnace

To understand the stress, we must first understand the environment and the sequence of events the pusher plate experiences.

The Role of the Pusher Plate

A pusher plate is a critical component in a continuous sintering furnace. Its job is to transport parts, typically made from powdered metal, through different temperature zones in a controlled sequence.

The Sintering Hot Zone

The first major stage is the hot zone, where temperatures are high enough to cause the metal particles to fuse together, giving the part its strength and density. The pusher plate "soaks" at this high temperature along with the parts it carries.

The Source of Extreme Thermal Shock

The severe load isn't caused by the heat itself, but by the extreme rate of change in temperature that follows.

Combining Sintering and Hardening

Many modern processes are designed for maximum efficiency. Instead of moving sintered parts to a separate furnace for heat treatment and hardening, a quench zone is placed immediately after the sintering hot zone.

The Physics of the Quench

As the hot pusher plate exits the sintering zone, it is immediately subjected to rapid cooling in the quench zone. This creates a massive and instantaneous temperature differential across the material.

The Material's Violent Reaction

This rapid cooling causes the plate's outer surface to contract violently while its inner core remains hot and expanded. This internal conflict between the contracting surface and the expanded core generates immense internal stresses, which is the definition of thermal shock.

Understanding the Trade-offs

The decision to use this combined process is based on a clear cost-benefit analysis, with the pusher plate caught in the middle.

The Benefit: Process Efficiency

Combining sintering and surface hardening into one continuous process saves enormous time, energy, and factory floor space. It eliminates the need for a second furnace and the associated material handling, dramatically improving throughput.

The Drawback: Extreme Material Stress

The cost of this efficiency is paid by the equipment. The pusher plate must be made from highly advanced materials, typically specialized ceramics or alloys, that can withstand repeated cycles of extreme thermal shock without cracking or failing. This increases component cost and necessitates rigorous inspection and maintenance schedules.

Making the Right Choice for Your Goal

Understanding this core conflict is essential for optimizing furnace design, material selection, and operational budgets.

- If your primary focus is maximizing component lifespan: You must invest in pusher plates made from materials with the highest possible thermal shock resistance and a low coefficient of thermal expansion.

- If your primary focus is process throughput: Accept that the combined process is superior but plan for the higher cost and shorter lifespan of pusher plates as a necessary operational expense.

- If your primary focus is reducing operational costs: Conduct a total cost of ownership analysis that weighs the upfront cost and replacement frequency of different plate materials against the efficiency gains of the combined process.

By recognizing the deliberate trade-off at the heart of the furnace's design, you can make informed decisions that balance manufacturing efficiency with material reliability.

Summary Table:

| Key Factor | Impact on Pusher Plate |

|---|---|

| Combined Process | Sintering and hardening in one furnace cycle for maximum efficiency. |

| Hot Zone Soak | Plate and parts are heated to high sintering temperatures (e.g., >1000°C). |

| Immediate Quench | Plate is rapidly cooled in the quench zone, creating a massive temperature differential. |

| Resulting Stress | Outer surface contracts violently while the inner core is still expanded, causing severe thermal shock. |

Optimize your sintering furnace's performance and protect your investment in pusher plates.

At KINTEK, we understand the extreme demands placed on lab equipment in high-throughput manufacturing environments. Our expertise in high-temperature materials and furnace components can help you:

- Select the right materials for superior thermal shock resistance.

- Extend component lifespan and reduce downtime.

- Balance process efficiency with equipment reliability and total cost of ownership.

Let our specialists provide a solution tailored to your specific lab needs. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What is the primary function of the pre-vacuum pump in SiC coating? Ensuring Substrate Integrity and Process Purity

- Why is a Quartz Reaction Tube necessary for gaseous formaldehyde removal activity testing systems?

- What is refractory material made of? Key Components for Extreme Heat Resistance

- What are the temperature sensors used in furnace? Achieve Precise Control with Type S Thermocouples

- Why is a reflux condenser required in lab reactors for biodiesel? Ensure Maximum Yield and Solvent Recovery

- Why is a high-purity quartz reactor essential for TiO2/CuxOy photocatalysis? Unlock Peak Optical Transmittance

- What is furnace lining? The Engineered System Protecting Your High-Temperature Processes

- What is the purpose of fluxing? The Essential Guide to Strong, Reliable Solder Joints