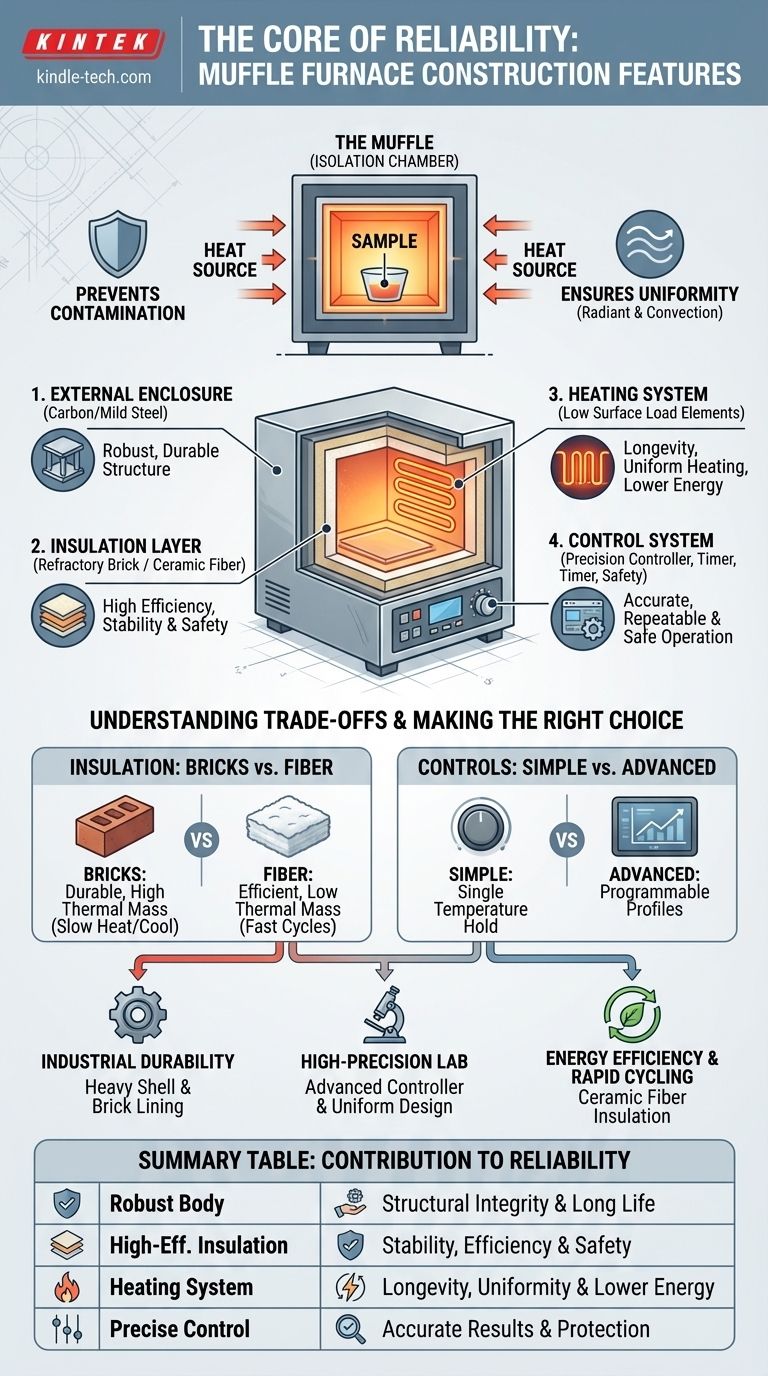

The practicality and reliability of a muffle furnace are a direct result of its core construction features. These include a robust external body made from materials like carbon steel, a highly insulated chamber using refractory bricks or ceramic fiber, an efficient heating system designed for longevity, and a precise control system to manage temperature and ensure safety. The central design principle is isolating the material being heated from the heating elements themselves.

The true reliability of a muffle furnace doesn't come from a single component, but from the synergy between its parts. Its primary function is to create a perfectly clean, stable, and uniform high-temperature environment by isolating the sample within a specialized chamber.

The Core Principle: Isolating the Sample

The defining feature of a muffle furnace is the "muffle" itself—an independent inner chamber that separates the workload from the heat source. This fundamental design choice is the source of its most significant benefits.

Preventing Contamination

The material is placed inside an airtight or semi-isolated chamber. This prevents any direct contact with the heating elements. In modern electric muffle furnaces, this ensures the sample remains pure and free from any pollutants that could alter its properties.

Historically, this design was critical for shielding materials from combustion by-products created by fuels like coal or gas. While most lab furnaces are now electric, this principle of isolation remains paramount for process integrity.

Ensuring Temperature Uniformity

The muffle chamber is constructed from heat-resistant materials with high thermal conductivity, such as a mix of silica and aluminum. Combined with evenly distributed heating elements, this design leverages both radiant and convection heat transfer to provide a highly homogeneous temperature throughout the chamber.

Deconstructing a Reliable Furnace: Key Components

A well-built muffle furnace integrates several key systems, each contributing to its overall performance and longevity.

The External Enclosure: Built for Durability

The outer body, or shell, is typically constructed from carbon steel sheets or a robust mild steel (MS) shell. This provides the structural integrity needed to handle continuous, high-temperature operation over a long service life.

The Insulation Layer: Maximizing Efficiency

Effective insulation is critical for both performance and safety. Furnaces use high-quality refractory bricks or ceramic fiber to line the chamber. This specialized covering provides powerful heat insulation, which reduces energy consumption, ensures temperature stability, and keeps the external surface cooler.

A ceramic fiber rope is often used to seal the door, preventing a major source of heat loss.

The Heating System: The Engine of the Furnace

The electric heating elements are the heart of the furnace. For reliability, they are often designed to operate at a low surface load. This reduces stress on the elements, significantly contributing to a longer, trouble-free operational life.

This design approach also results in a high-performance system with lower overall energy consumption, making the furnace more cost-effective to run.

The Control System: Precision and Safety

The control panel is the furnace's brain. A reliable temperature controller and sensor are essential for accurate and repeatable thermal processing.

Key controls include a temperature control to set and maintain the desired heat, a timer to manage process duration, and a safety switch to limit the electrical supply, protecting both the user and the equipment.

Understanding the Trade-offs

Choosing a muffle furnace involves balancing different construction priorities based on your specific needs.

Refractory Bricks vs. Ceramic Fiber

Refractory bricks are extremely durable and can withstand significant physical wear. However, they have high thermal mass, meaning they take longer to heat up and cool down.

Ceramic fiber insulation, on the other hand, is lighter and has lower thermal mass. This allows for faster heating and cooling cycles and often provides superior thermal efficiency, but it can be more susceptible to mechanical damage.

Simple vs. Advanced Controls

A basic furnace may have a simple analog or digital controller that holds a single temperature. More advanced models feature programmable controllers that can execute complex multi-stage heating and cooling profiles. The right choice depends entirely on the complexity of your thermal processing requirements.

Making the Right Choice for Your Application

To select a furnace, match its construction features to your primary goal.

- If your primary focus is industrial durability: Prioritize a furnace with a heavy-gauge mild steel shell and a dense refractory brick lining.

- If your primary focus is high-precision lab work: Look for a system with a programmable temperature controller and a design that emphasizes homogeneous temperature distribution.

- If your primary focus is energy efficiency and rapid cycling: A furnace built with ceramic fiber insulation will provide the best performance.

Ultimately, a furnace's reliability is a direct reflection of the quality of its materials and the intelligence of its design.

Summary Table:

| Construction Feature | Contribution to Reliability & Practicality |

|---|---|

| Robust External Body (Carbon/Mild Steel) | Provides structural integrity and long service life. |

| High-Efficiency Insulation (Refractory Brick/Ceramic Fiber) | Ensures temperature stability, energy efficiency, and safety. |

| Heating System (Low Surface Load Elements) | Offers longevity, uniform heating, and lower energy consumption. |

| Precise Control System (Controller, Timer, Safety Switch) | Guarantees accurate, repeatable results and user/equipment protection. |

Ready to enhance your lab's capabilities with a reliable muffle furnace? KINTEK specializes in high-performance lab equipment designed for durability and precision. Whether your priority is industrial-grade toughness, high-precision temperature control, or energy-efficient rapid cycling, we have the right solution for your laboratory needs. Contact us today to discuss your specific application and find the perfect furnace for your workflow!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the specs of a muffle furnace? A Guide to Key Features & Selection

- How does a high-temperature muffle furnace contribute to the preparation of LLZO fillers? Optimizing Ionic Conductivity

- Why is a high-temperature muffle furnace used for calcination at 900°C? Optimizing Ferrocolumbite Residue Stability

- What is the purpose of using a high-temperature furnace to calcinate SiC? Optimize 2024Al/Gr/SiC Composite Performance

- What are the safety precautions for muffle furnace? A Complete Guide to Safe High-Temperature Operation

- What is the mechanism of a muffle furnace? Master Precise, Contaminant-Free Heating

- What is the significance of using a high-temperature muffle furnace in the solid-state transformation of CuFe12O19?

- Why is pre-calcination of CaO necessary for CCMS? Ensure High-Purity Calcium Oxide in Your Molten Salt Process