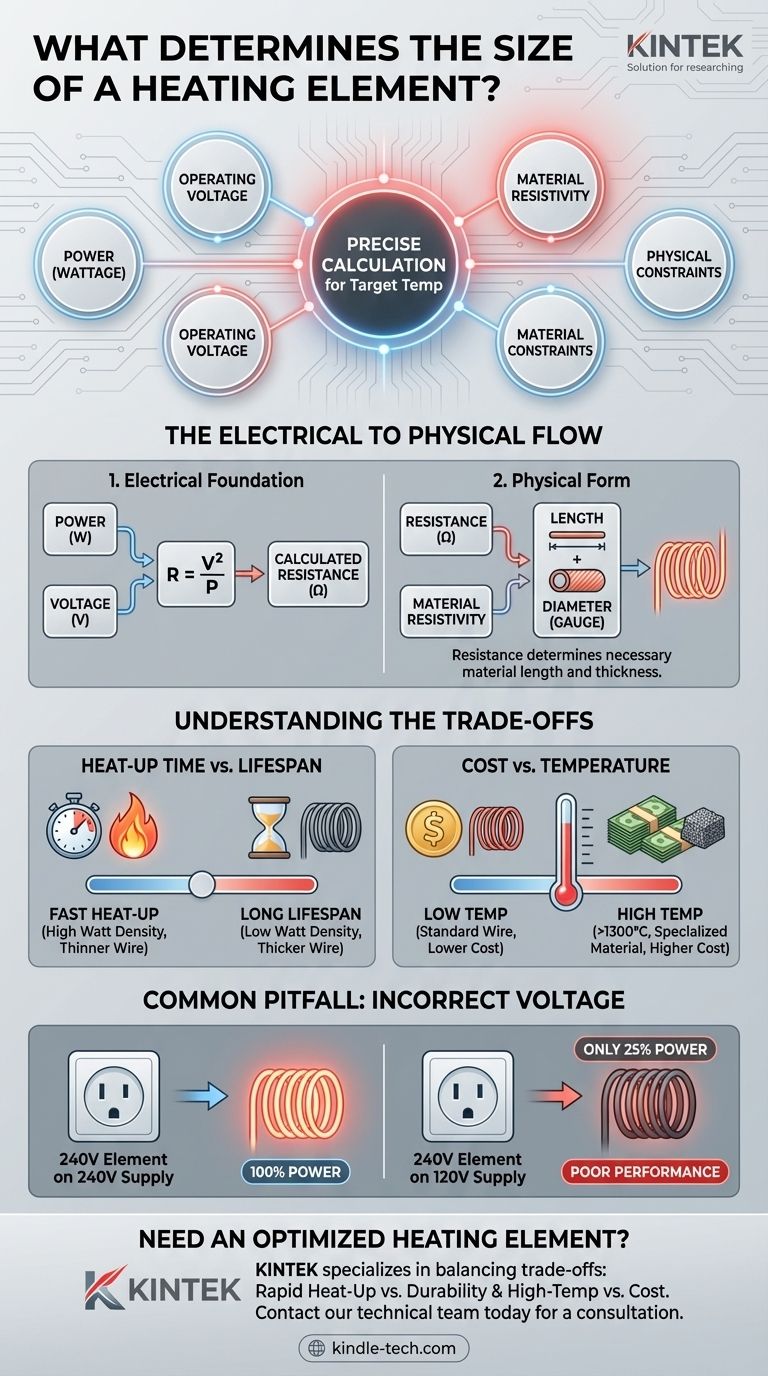

The size of a heating element is a direct consequence of four interdependent factors: the required power output (wattage), the operating voltage, the resistive properties of the element's material, and the physical constraints of the application. These factors are not chosen independently; they are part of a precise calculation to safely and effectively generate a target temperature.

The core principle is that a heating element's size isn't arbitrary. It is the physical manifestation of an electrical calculation where the desired heat output (power) and the available electricity (voltage) dictate a specific resistance, which can only be achieved with a precise length and thickness of a chosen material.

The Electrical Foundation: Power, Voltage, and Resistance

Before we can determine the physical dimensions of an element, we must first define its required electrical properties. This is a three-step process rooted in fundamental electrical laws.

The Goal: Required Power (Wattage)

The entire purpose of a heating element is to convert electrical energy into heat. The rate of this conversion is measured in watts (W).

A higher wattage means more heat is produced per unit of time. The required wattage is determined by the application: how much mass needs to be heated, how quickly it needs to reach temperature, and how much heat is lost to the surroundings.

The Constraint: Operating Voltage

The heating element must be designed to operate on a specific, fixed voltage (V) from the power source, such as 120V or 240V for standard applications.

This voltage is a non-negotiable input for the sizing calculation. An element designed for 240V will perform poorly and may fail if connected to a 120V source.

The Result: Calculated Resistance

With the required power and the operating voltage defined, we can calculate the necessary electrical resistance (Ω) of the element using the power law formula: Resistance = Voltage² / Power.

This calculated resistance is the critical link. It is the specific electrical property that the physical element must possess.

From Electrical Need to Physical Form

Once the target resistance is known, we can translate that electrical requirement into the physical dimensions of length and diameter.

Material Resistivity

Every conductive material has an intrinsic property called resistivity. This measures how strongly the material opposes the flow of electric current for a given cross-sectional area and length.

Materials like resistance wire (e.g., Nichrome) are chosen for their high resistivity and ability to withstand high temperatures without degrading. As noted, materials like silicon carbide are used for even higher temperature requirements (above 1300°C).

Determining Length

To achieve the total target resistance, a specific length of the chosen material is required. Because the material has a known resistance per foot (or meter), the calculation is straightforward.

If you need more total resistance, you need a longer element. This is why high-wattage heating elements are often coiled—to fit a very long piece of wire into a compact space.

Determining Diameter (Gauge)

The thickness or diameter of the wire is just as critical as its length. A thicker wire has lower resistance per foot and can carry more current without burning out.

This is governed by a principle called watt density—the amount of power dissipated per unit of surface area of the element. If the watt density is too high (too much power in a thin wire), the element will overheat and fail quickly. A thicker wire provides more surface area, lowering the watt density and leading to a longer operational life.

Understanding the Trade-offs

Selecting a heating element's size involves balancing competing priorities. There is no single "best" size, only the optimal size for a specific goal.

Heat-Up Time vs. Element Lifespan

An element with a high watt density (a thinner or smaller element for its power rating) will heat up very quickly. However, it runs hotter and is under more thermal stress, leading to a shorter lifespan. Conversely, a low watt density element (thicker wire) will last much longer but may respond more slowly to temperature changes.

Cost vs. Temperature Requirement

As the required operating temperature increases, the choice of materials becomes limited and more expensive. A standard resistance wire is excellent for temperatures up to 1200°C, but pushing it beyond its limits will cause immediate failure.

Choosing a high-temperature material like silicon carbide for a low-temperature application is possible, but it represents unnecessary expense. The temperature requirement is often the first and most important decision.

The Pitfall of Incorrect Voltage

A common mistake is using an element designed for one voltage on a different one. For example, using a 240V element on a 120V supply will result in it producing only 25% of its rated power, leading to extremely poor performance.

Making the Right Choice for Your Application

Your final decision should be guided by the primary goal of your heating application.

- If your primary focus is rapid heating: You will need an element with a higher watt density, which likely means a more compact but potentially less durable design.

- If your primary focus is longevity and reliability: Opt for an element with a lower watt density, which will be physically larger and thicker for the same power output.

- If your primary focus is high-temperature operation (above 1200°C): Your material choice becomes the most critical factor, which will in turn dictate the element's form factor and overall cost.

Ultimately, a correctly sized heating element is the result of careful engineering that balances electrical principles with the physical demands of the task.

Summary Table:

| Factor | Role in Determining Size | Key Consideration |

|---|---|---|

| Power (Wattage) | Defines the total heat output required. | Higher wattage typically requires a larger element. |

| Operating Voltage | Sets the electrical constraint for the design. | Must match the power supply; incorrect voltage leads to failure. |

| Material Resistivity | Dictates the material's inherent resistance to current. | High-temperature materials (e.g., silicon carbide) enable smaller sizes at extreme temps. |

| Length & Diameter | The physical result of the resistance calculation. | Longer length increases resistance; thicker diameter lowers watt density for longer life. |

Need a Heating Element Optimized for Your Specific Application?

Choosing the correct size and material is critical for performance, safety, and equipment longevity. The experts at KINTEK specialize in designing and supplying precision heating elements for laboratory and industrial equipment.

We help you balance the key trade-offs:

- Rapid Heat-Up vs. Long-Term Durability

- High-Temperature Performance vs. Cost-Effectiveness

Whether you require standard resistance wire or high-temperature silicon carbide elements, KINTEK provides the right solution for your lab's unique needs.

Contact our technical team today for a consultation to ensure your heating application is efficient, reliable, and built to last.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What is the temperature limit of silicon carbide? Maximize Performance from 1600°C to 2500°C

- What is special about tungsten? The Ultimate Metal for Extreme Heat & Wear Resistance

- What are the properties of molybdenum heating element? Choose the Right Type for Your Furnace Atmosphere

- How do coaxial heating coils in a TDS system determine hydrogen trap activation energy? Precise Thermal Control Guide

- What uses resistive heating? From Toasters to Furnaces, Harnessing Simple, Direct Heat

- Do heating elements use a lot of electricity? Understanding High Energy Consumption and Efficient Alternatives

- What is the function of glass-ceramic heaters in high-temperature evaporation? Ensure Thermal Precision & Stability

- What is the life expectancy of a heating element? Maximize Lifespan with Proper Care