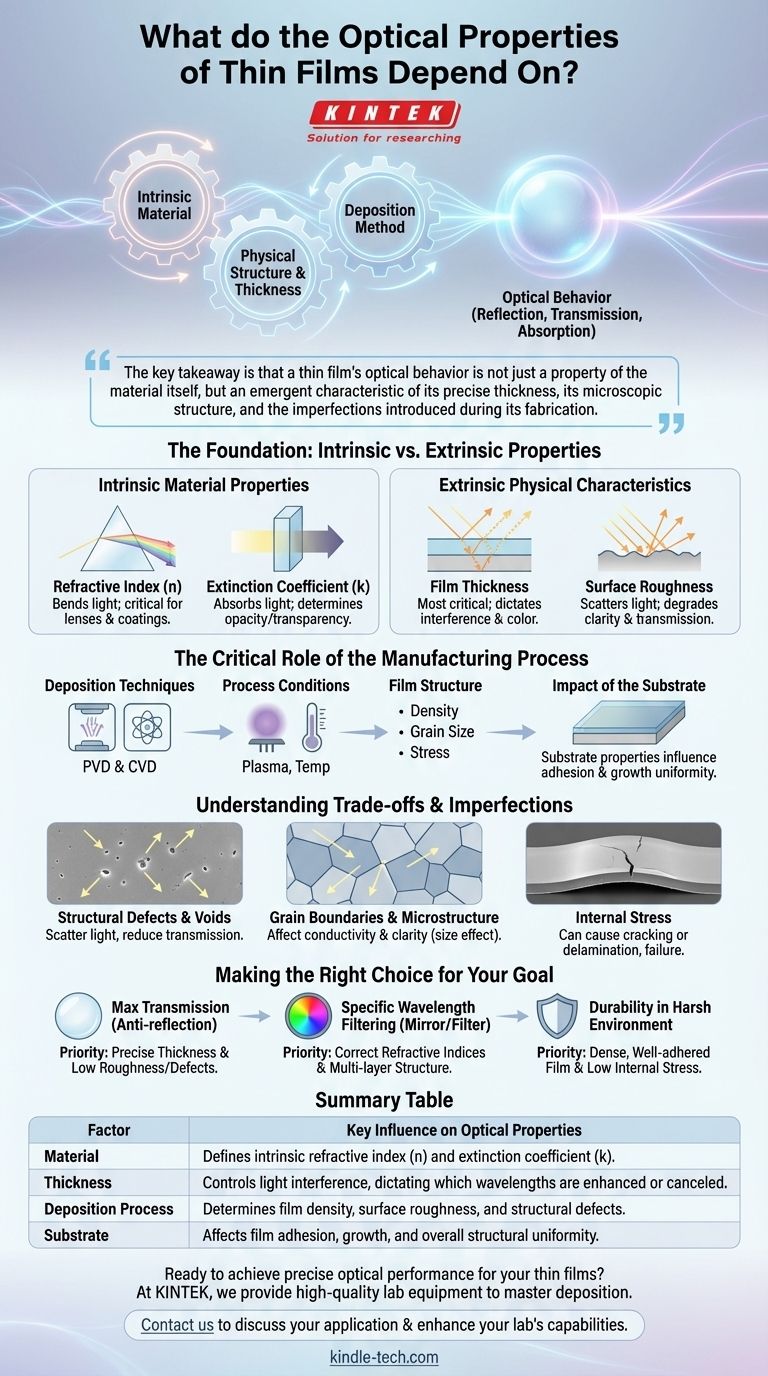

At its core, the optical properties of a thin film depend on three interconnected factors: the intrinsic material used, the film's physical structure and thickness, and the specific deposition method used to create it. These elements work in concert to determine how the film reflects, transmits, and absorbs light.

The key takeaway is that a thin film's optical behavior is not just a property of the material itself, but an emergent characteristic of its precise thickness, its microscopic structure, and the imperfections introduced during its fabrication.

The Foundation: Intrinsic vs. Extrinsic Properties

To understand a thin film, we must separate the inherent properties of the material from the characteristics imposed upon it by its structure and manufacturing process.

Intrinsic Material Properties

The starting point for any thin film is the bulk material it is made from. Its fundamental optical character is defined by two key parameters.

Refractive Index (n): This value describes how much the material can bend light. A higher refractive index means a greater bending effect, which is critical for designing lenses and reflective coatings.

Extinction Coefficient (k): This value describes how much light the material absorbs at a given wavelength. Materials with a high extinction coefficient are opaque, while those with a low value are transparent.

Extrinsic Physical Characteristics

How the material is structured as a film dramatically alters its interaction with light.

Film Thickness: This is arguably the most critical parameter. The thickness of the film, often controlled down to the nanometer, dictates which wavelengths of light interfere constructively (enhancing reflection) or destructively (canceling reflection).

Surface Roughness: A perfectly smooth film behaves predictably. However, surface roughness can scatter light in unintended directions, which often degrades performance by reducing transmission and clarity.

The Critical Role of the Manufacturing Process

A thin film is not simply a slice of a bulk material; it is constructed atom by atom. The method of its construction fundamentally defines its final properties.

Deposition Techniques

The specific technique used—such as physical vapor deposition (PVD) or chemical vapor deposition (CVD)—and the conditions of that process (e.g., plasma parameters, temperature) determine the film's final structure.

These conditions control the density, grain size, and internal stress of the film, all of which influence its refractive index and durability.

The Impact of the Substrate

A thin film is always deposited onto a substrate. The properties of this underlying material, including its surface chemistry and smoothness, directly influence how the film adheres and grows, which in turn affects its structural uniformity.

Understanding the Trade-offs and Imperfections

In the real world, no thin film is perfect. Understanding the common imperfections is key to controlling their optical effects.

Structural Defects and Voids

The deposition process can create microscopic imperfections, such as voids (empty spaces) or dislocations in the crystalline structure.

These defects act as scattering points for light, which can reduce transmission, increase haze, and alter the intended optical performance of the coating.

Grain Boundaries and Microstructure

Unlike a single perfect crystal, most thin films are polycrystalline, composed of many small crystal "grains."

The boundaries between these grains act as additional scattering points for light waves, which can affect the film's conductivity and its overall optical clarity. This is a "size effect," where the film's properties differ significantly from the bulk material due to its constrained dimensions.

Internal Stress

The deposition process often builds mechanical stress into the film. While this can sometimes improve hardness, high stress can cause cracking or delamination.

Any such physical failure results in a catastrophic loss of the film's intended optical properties.

Making the Right Choice for Your Goal

Controlling a thin film's optical properties means manipulating these variables to achieve a specific outcome.

- If your primary focus is maximum transmission (e.g., anti-reflection coatings): Your priority is precise thickness control and using a deposition method that minimizes surface roughness and internal defects.

- If your primary focus is specific wavelength filtering (e.g., mirror or filter): Your priority is selecting materials with the correct refractive indices and building a precise multi-layer structure with exacting thickness control for each layer.

- If your primary focus is durability in a harsh environment: Your priority is choosing a deposition process that creates a dense, well-adhered film with low internal stress, even if it means a slight compromise on peak optical performance.

Ultimately, mastering thin film optics is about understanding and controlling the interplay between material, structure, and process to achieve your desired result.

Summary Table:

| Factor | Key Influence on Optical Properties |

|---|---|

| Material | Defines intrinsic refractive index (n) and extinction coefficient (k). |

| Thickness | Controls light interference, dictating which wavelengths are enhanced or canceled. |

| Deposition Process | Determines film density, surface roughness, and structural defects. |

| Substrate | Affects film adhesion, growth, and overall structural uniformity. |

Ready to achieve precise optical performance for your thin films?

At KINTEK, we specialize in providing the high-quality lab equipment and consumables needed to master thin film deposition. Whether your goal is maximum transmission, specific wavelength filtering, or superior durability, our solutions help you control material, thickness, and process variables for perfect results.

Contact us today to discuss your specific application and discover how KINTEK can enhance your laboratory's capabilities.

Get in touch with our experts →

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Optical Window Glass Substrate Wafer CaF2 Substrate Window Lens

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Infrared High Resistance Single Crystal Silicon Lens

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

People Also Ask

- What is step coverage in film deposition and how is it calculated? Master Uniformity for Complex Substrates

- What is the meaning of synthesis of graphene? A Guide to Top-Down vs. Bottom-Up Methods

- Is carbon nanotube a simple molecular structure? Unveiling the Complex Atomic Architecture

- What is the unit of deposition rate? Mastering Thin-Film Control for Precision Manufacturing

- What is the alternative material for graphene? Discover the Top 2D Materials for Your Specific Application

- How is graphene made and what is the process? A Guide to Top-Down vs. Bottom-Up Methods

- What is the reactive sputtering technique? Synthesize Advanced Thin Films with Precision

- What are the target materials for sputtering? From Metals to Ceramics for Precise Thin Films