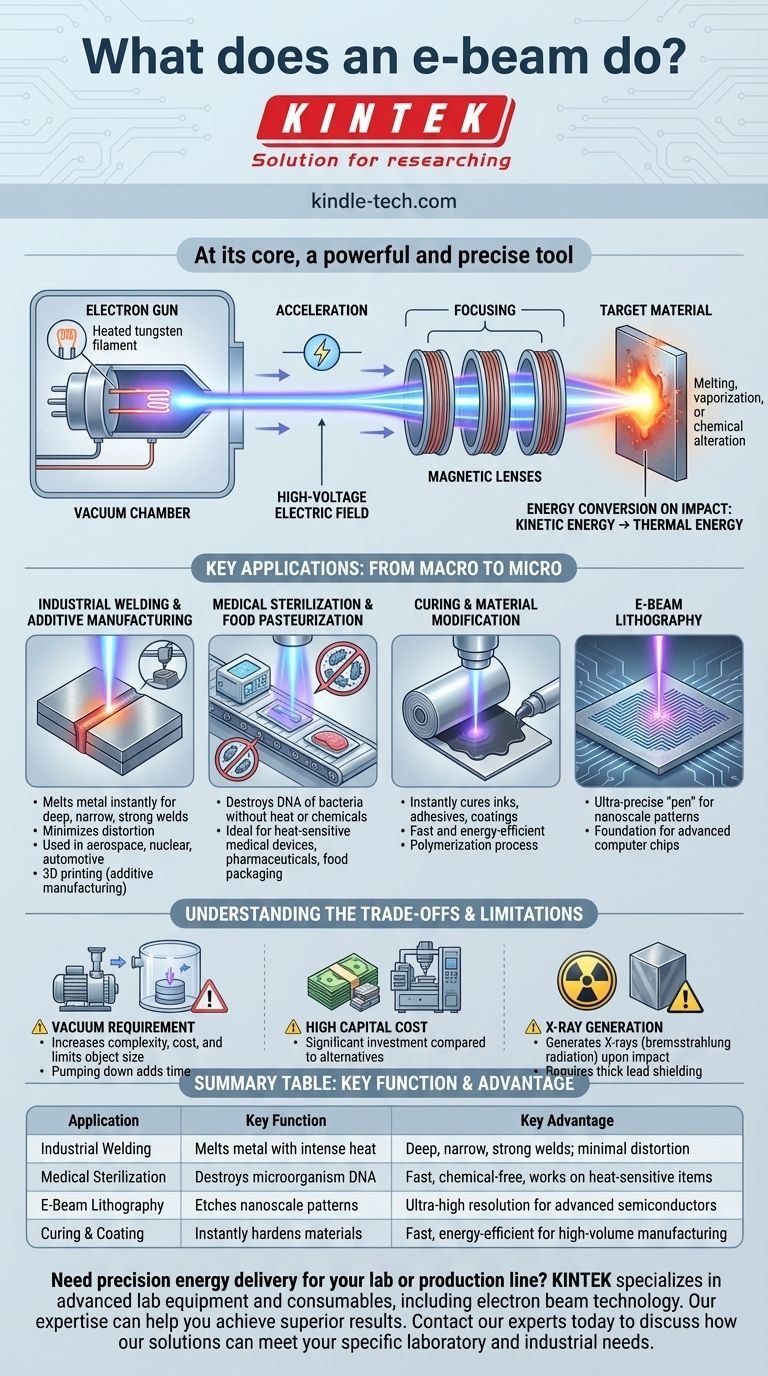

At its core, an e-beam, or electron beam, is a highly focused stream of electrons accelerated to high speeds in a vacuum. This beam acts as a powerful and precise tool for transferring energy and altering materials, enabling applications from welding thick metal plates in the aerospace industry to etching microscopic circuits onto a silicon chip.

An electron beam is not a single tool but a highly versatile form of energy delivery. By precisely controlling the beam's power and focus, it can be adapted to achieve vastly different outcomes, from gently sterilizing a medical device to vaporizing metal for advanced manufacturing.

How an Electron Beam Works: The Core Principles

To understand what an e-beam does, we must first understand how it is formed and controlled. The entire process takes place inside a vacuum chamber to prevent the electrons from scattering off air molecules.

Generating the Electrons

It all begins with an electron gun. A filament, typically made of tungsten, is heated to an extremely high temperature, causing it to release a cloud of electrons through a process called thermionic emission.

Acceleration and Focusing

These free electrons are then accelerated by a high-voltage electric field, which propels them toward their target at speeds that can approach a significant fraction of the speed of light.

Much like a glass lens focuses a beam of light, a series of magnetic lenses (electromagnetic coils) are used to shape and focus the stream of electrons into a narrow, high-energy beam.

Energy Conversion on Impact

The immense power of an e-beam comes from the conversion of the electrons' kinetic energy into thermal energy when they strike the target material. This intense, localized heating is what allows the beam to melt, vaporize, or chemically alter the workpiece.

Key Applications: From Macro to Micro

The ability to control the beam's energy density (the amount of power focused on a specific spot) makes it useful for a remarkably wide range of tasks.

Industrial Welding and Additive Manufacturing

High-power e-beams can melt metal almost instantly. This allows for incredibly deep, narrow, and strong welds with a very small heat-affected zone, minimizing distortion in critical components used in aerospace, nuclear, and automotive industries. This same principle is used in 3D printing (additive manufacturing) to melt and fuse layers of metal powder.

Medical Sterilization and Food Pasteurization

A broader, less intense e-beam can be used to sterilize surfaces. The high-energy electrons effectively destroy the DNA of bacteria and other microorganisms without using high heat or harsh chemicals. This makes it ideal for sterilizing heat-sensitive medical devices, pharmaceuticals, and food packaging.

Curing and Material Modification

In manufacturing, e-beams are used to instantly cure inks, adhesives, and coatings on various surfaces. The beam initiates a chemical reaction (polymerization) that hardens the liquid material, a process that is both fast and energy-efficient.

E-Beam Lithography

At the opposite end of the power scale, a very fine, low-power e-beam is used as an ultra-precise "pen" in the semiconductor industry. It draws nanoscale patterns onto a silicon wafer coated with an electron-sensitive material (a "resist"), forming the foundation for the most advanced computer chips.

Understanding the Trade-offs and Limitations

While powerful, e-beam technology is not universally applicable. Understanding its inherent constraints is crucial for making informed decisions.

The Vacuum Requirement

The need for a vacuum chamber is the most significant limitation. It increases the equipment's complexity and cost, and it limits the size of the object that can be processed. Pumping down the chamber also adds time to batch-processing operations.

High Capital Cost

E-beam systems, including the electron gun, high-voltage power supplies, magnetic lenses, and vacuum chamber, represent a significant capital investment compared to some alternative technologies like lasers or chemical processes.

X-Ray Generation

A critical safety consideration is that when high-energy electrons strike a material, they generate X-rays (bremsstrahlung radiation). This necessitates thick lead shielding around the equipment to protect operators, adding to the system's weight, cost, and complexity.

Making the Right Choice for Your Goal

The decision to use an e-beam depends entirely on the specific requirements of the task.

- If your primary focus is high-integrity, deep welds in critical components: E-beam welding provides unparalleled depth-to-width ratios and minimal material distortion.

- If your primary focus is rapidly sterilizing heat-sensitive products: E-beam sterilization offers a fast, reliable, and chemical-free method with excellent material penetration.

- If your primary focus is creating prototypes for next-generation semiconductors: E-beam lithography is the essential tool for achieving the ultra-high resolution required for nanoscale features.

- If your primary focus is instantly curing inks or coatings on a substrate: E-beam curing is an extremely fast and energy-efficient process for high-volume manufacturing.

Ultimately, an electron beam is a powerful demonstration of how controlling fundamental particles can unlock revolutionary capabilities across science and industry.

Summary Table:

| Application | Key Function | Key Advantage |

|---|---|---|

| Industrial Welding | Melts metal with intense heat | Deep, narrow, strong welds; minimal distortion |

| Medical Sterilization | Destroys microorganism DNA | Fast, chemical-free, works on heat-sensitive items |

| E-Beam Lithography | Etches nanoscale patterns | Ultra-high resolution for advanced semiconductors |

| Curing & Coating | Instantly hardens materials | Fast, energy-efficient for high-volume manufacturing |

Need precision energy delivery for your lab or production line? KINTEK specializes in advanced lab equipment and consumables, including electron beam technology. Whether you're developing new materials, sterilizing medical devices, or pushing the limits of microfabrication, our expertise can help you achieve superior results. Contact our experts today to discuss how our solutions can meet your specific laboratory and industrial needs.

Visual Guide

Related Products

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

People Also Ask

- What is the difference between evaporation and electron beam lithography? Understanding Patterning vs. Deposition

- What thin films are deposited by electron beam evaporation? Unlock High-Performance Coatings

- What materials are used in vacuum evaporation? A Guide to Metals, Alloys, and Dielectrics

- What metals can be deposited by vacuum deposition? Achieve Precise Surface Properties for Your Application

- How does e-beam evaporation work? A Guide to High-Purity Thin Film Deposition

- What is the thermal evaporation technique for thin film deposition? A Guide to Simple, High-Purity Coating

- What is thermal evaporation of thin film? A Guide to High-Purity PVD Coating

- How does the vacuum evaporation system work? A Guide to Thin Film Deposition