In short, vulcanizing a tire is a specialized repair process that uses heat and pressure to chemically bond a new piece of rubber to a damaged area. Unlike a simple plug or patch, this method effectively re-molds the tire, creating a seamless and permanent repair that restores the tire's structural integrity.

Tire vulcanization is not just about patching a hole; it is a chemical process that fuses the repair material with the tire itself, creating a single, solid piece of rubber for maximum strength and safety.

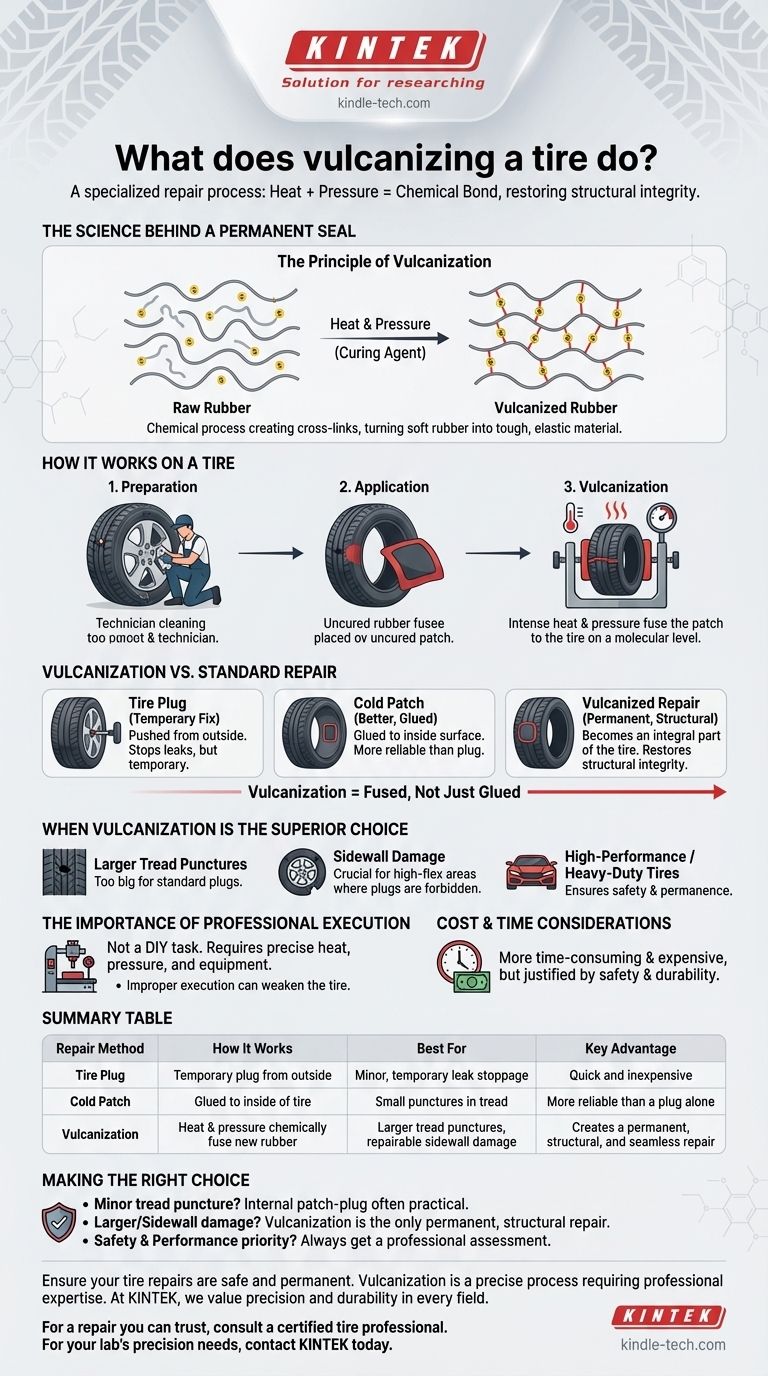

The Science Behind a Permanent Seal

To understand why vulcanization is a superior repair method, we must look beyond the simple act of covering a hole. The process fundamentally changes the molecular structure of the rubber.

The Principle of Vulcanization

At its core, vulcanization is a chemical process that makes rubber stronger and more durable. It involves adding a curing agent (like sulfur) to raw rubber and applying heat, which creates cross-links between the rubber's polymer chains. This turns a soft, pliable material into a tough, elastic one—the very process used to create a tire in the first place.

How It Works on a Tire

When a tire is vulcanized for repair, a technician cleans and prepares the punctured area. A piece of special, uncured rubber is applied over the damage. The area is then placed in a clamp that applies both intense pressure and controlled heat, initiating the vulcanization process and fusing the patch to the tire on a molecular level.

Vulcanization vs. a Standard Repair

A standard tire plug is a temporary fix pushed in from the outside to stop a leak. A cold patch, while better, is essentially glued to the inside surface of the tire. A vulcanized repair, by contrast, becomes an integral part of the tire itself, not just an addition to it.

Understanding the Trade-offs and Applications

While vulcanization offers a robust solution, it is not always necessary or appropriate for every type of tire damage.

When Vulcanization Is the Superior Choice

This method is the definitive solution for larger punctures in the tread area that are too big for a standard plug. Crucially, it is often the only safe way to repair damage to a tire's sidewall, an area where standard plugs are forbidden due to the high-flex nature of the rubber.

The Importance of Professional Execution

Tire vulcanization is not a DIY task. It requires specialized machinery to apply the precise heat and pressure needed for a successful bond. Improper execution can weaken the tire casing, making the repair unreliable or even dangerous.

Cost and Time Considerations

Because it is a more involved, technical process, vulcanization is more time-consuming and expensive than a standard plug or cold patch repair. Its use is justified by the safety and permanence of the repair, especially on high-performance or heavy-duty tires.

Making the Right Repair Choice for Your Tire

Choosing the correct repair method is critical for your safety and the longevity of your tire.

- If you have a minor puncture in the main tread area: A professionally installed internal patch-plug combination is often the most practical and cost-effective solution.

- If you have a larger puncture or repairable sidewall damage: Vulcanization is the only method that offers a safe, permanent, and structural repair by fusing the rubber.

- If safety and performance are your top priorities: Always have any tire damage assessed by a qualified professional to determine if vulcanization is the appropriate and necessary procedure.

Understanding the difference between a simple fix and a structural repair empowers you to make the safest decision for your vehicle.

Summary Table:

| Repair Method | How It Works | Best For | Key Advantage |

|---|---|---|---|

| Tire Plug | A temporary plug inserted from the outside. | Minor, temporary leak stoppage. | Quick and inexpensive. |

| Cold Patch | A patch is glued to the inside of the tire. | Small punctures in the tread area. | More reliable than a plug alone. |

| Vulcanization | Heat and pressure chemically fuse new rubber to the tire. | Larger tread punctures, repairable sidewall damage. | Creates a permanent, structural, and seamless repair. |

Ensure your tire repairs are safe and permanent.

Vulcanization is a precise process that requires professional equipment and expertise to ensure the structural integrity of your tire is restored. At KINTEK, we understand the critical need for reliability and safety in all applications. While we specialize in supplying high-performance laboratory equipment and consumables, we value precision and durability in every field.

For a repair you can trust, always consult a certified tire professional. If your work demands the same level of precision and quality for your lab, contact KINTEK today to discuss how our solutions can meet your specific laboratory needs.

Visual Guide

Related Products

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Touchscreen Automatic Vacuum Heat Press

People Also Ask

- What is cheaper than injection molding? Discover Cost-Effective Alternatives for Low-Volume Production

- What is the difference between monolayer and multilayer film? Choose the Right Packaging for Your Product

- What is the disadvantage of a two-roll mill? Limited Thickness Reduction Due to Roll Flattening

- What products can be made with injection molding? The Engine of Mass Production

- What does a rubber mixer do? Transform Raw Ingredients into a High-Performance Compound

- What is the principle of mixing on open two roll mill? Master Shear, Compression & Heat for Uniform Blending

- What is twin screw extrusion? Achieve Superior Mixing and Uniform Product Quality

- What does a blown film machine do? Transform Plastic Pellets into Versatile Film