To protect your sample from electrostatic discharge (ESD), you must either use a sample holder specifically designed to be anti-static or perform a static elimination process on a standard holder before bringing it near the sample. This initial step is critical for preventing irreversible damage to sensitive materials, especially in electronics or materials science applications.

The core issue extends beyond a single zap of static electricity. True sample protection requires a holistic approach where ESD prevention is the starting point, followed by rigorous protocols for cleanliness, mechanical handling, and environmental control to ensure the integrity of your entire experiment.

The Core of Electrostatic Protection

The primary goal is to create an environment where a static charge cannot build up on the holder or, if it does, can be safely dissipated before it can arc to the sample.

Method 1: Use an Anti-Static Holder

An anti-static sample holder is constructed from materials that are either inherently static dissipative or conductive. These materials prevent a significant electrical charge from accumulating on their surface.

By using a holder designed for this purpose, you are building safety directly into your experimental setup, making it the most reliable method for ESD prevention.

Method 2: Perform Static Elimination

If you are using a standard holder, you must actively perform a static elimination process before use. This involves neutralizing any existing charge on the holder's surface.

Common techniques include using an ionized air blower to neutralize the holder or grounding the holder (and the operator) via an anti-static wrist strap connected to a common ground point. This step must be performed every time before the holder approaches the sample.

Why This Matters: The Risk of ESD

Electrostatic discharge (ESD) is the sudden flow of electricity between two electrically charged objects. For sensitive samples like semiconductors, thin-film devices, or biological specimens, this discharge can be catastrophic.

An ESD event can instantly destroy microscopic circuits, alter material properties, or render your data useless, often without any visible sign of damage.

Beyond ESD: Ensuring Total Experimental Integrity

Preventing static is only one part of proper sample handling. To achieve reliable and repeatable results, you must consider the holder's physical and chemical condition.

The Critical Role of Cleanliness

Ensure the conductive sheet of the holder and the sample surface are impeccably clean. Contaminants like grease, dust, or other impurities can interfere with proper electrical contact and contaminate the sample.

If the conductive sheet is dirty, clean it with deionized water and allow it to dry completely. Crucially, avoid touching the sample surface with your hands to prevent transferring oils and salts.

Mechanical Stability and Handling

Before every use, verify the holder's mechanical integrity. Check that the clip head opens and closes smoothly and that all fastening components, like screws, are in good condition.

A secure holder prevents the sample from moving or falling during transfer. When placing the holder into a vacuum chamber, for example, move it slowly to avoid creating airflow that could dislodge the sample.

Understanding Operational Constraints

A sample holder is a precision tool with clear limitations. Exceeding them can damage the holder, compromise the experiment, and even pose a safety risk.

The High-Temperature Constraint

Most standard sample holders are designed for use at room temperature. High temperatures can permanently alter the holder's structure, affecting its precise dimensions, electrical conductivity, and chemical stability.

The High-Pressure Constraint

Similarly, do not use the holder in high-pressure environments unless it is explicitly designed for that purpose. Excessive pressure can cause mechanical failure, damaging both the sample and the surrounding equipment.

Adherence to Procedure

Always follow the specific operating procedures for your equipment and experiment. Mishandling the holder by applying excessive force, causing collisions, or using it in an incompatible chemical environment can lead to immediate and irreversible damage.

Applying These Principles to Your Work

Your specific focus will determine which precautions are most critical.

- If your primary focus is preventing damage to sensitive electronics: Prioritize using a dedicated anti-static holder or implementing a strict static elimination and grounding protocol before every use.

- If your primary focus is achieving repeatable electrical measurements: Emphasize the cleanliness of all conductive contact points and the mechanical stability of the holder to ensure a consistent connection.

- If your primary focus is process safety and equipment longevity: Strictly adhere to the holder's operational limits for temperature and pressure, and follow all established handling procedures without deviation.

By treating the sample holder as a critical instrument rather than a simple accessory, you ensure the integrity and success of your work.

Summary Table:

| Protection Measure | Key Action | Primary Benefit |

|---|---|---|

| Use Anti-Static Holder | Employ conductive/dissipative materials | Prevents static charge buildup |

| Static Elimination | Use ionized air blower/grounding | Neutralizes existing charges |

| Cleanliness Protocol | Clean with deionized water, avoid hand contact | Ensures proper electrical contact |

| Mechanical Check | Verify clip function and fasteners | Prevents sample movement/damage |

| Operational Limits | Adhere to temperature/pressure specs | Protects holder and equipment |

Protect your sensitive samples with precision equipment from KINTEK

Are you working with semiconductors, thin-film devices, or other ESD-sensitive materials? KINTEK specializes in laboratory equipment and consumables designed to meet your exact sample handling needs. Our anti-static sample holders and static control solutions help you:

- Prevent irreversible ESD damage to valuable samples

- Maintain experimental integrity with reliable, clean surfaces

- Achieve consistent, repeatable results in your research

Let our experts help you select the right equipment for your specific application. Contact our technical team today for personalized recommendations and ensure the success of your critical experiments.

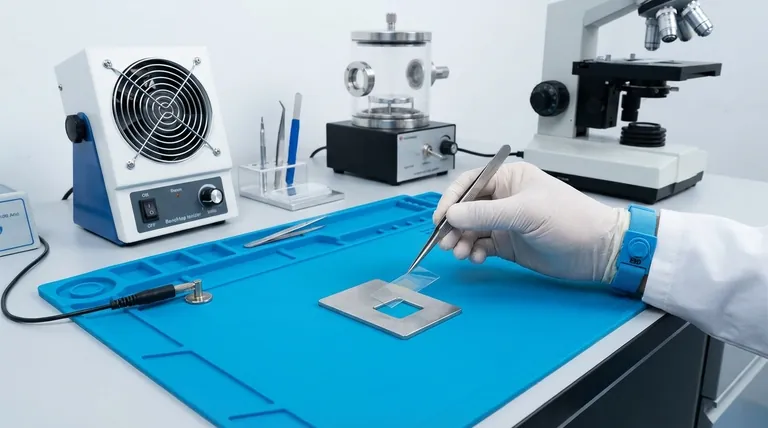

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- How should a sample holder be handled to ensure its longevity? Protect Your Lab Investment and Data Integrity

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference

- What is the minimum sample required for XRD analysis? Optimize Your Material Analysis

- What are the limitations of the IR spectroscopy? Understanding Its Boundaries for Accurate Analysis

- What affects melting point chemistry? A Guide to Molecular Forces and Lattice Energy