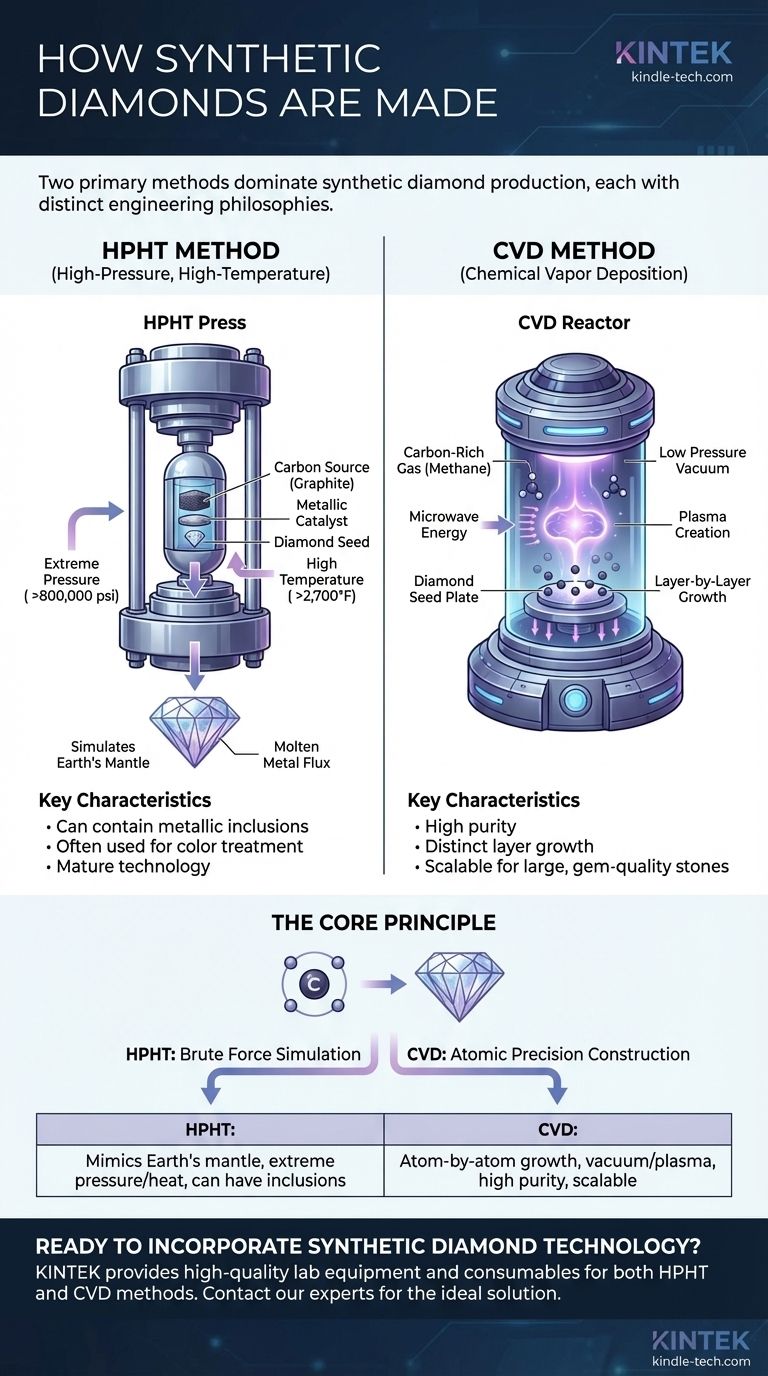

At its core, the equipment used to create synthetic diamonds falls into two primary categories. The first is a high-pressure, high-temperature (HPHT) press, which mimics the intense conditions deep within the Earth's mantle. The second is a chemical vapor deposition (CVD) reactor, a vacuum chamber that builds a diamond atom-by-atom from a carbon-rich gas.

The choice between an HPHT press and a CVD reactor is not about which is "better," but which engineering philosophy to follow: simulating the brute force of nature versus constructing a diamond with atomic precision. Each method leaves a distinct, identifiable fingerprint on the final stone.

The Two Dominant Production Methods

While minor techniques exist for creating nanodiamonds, such as detonation synthesis, the global market for synthetic diamonds is dominated by two highly refined industrial processes. These are the High-Pressure, High-Temperature (HPHT) method and the Chemical Vapor Deposition (CVD) method.

Each process relies on fundamentally different equipment and scientific principles to achieve the same result: transforming carbon into a crystalline diamond structure.

The High-Pressure, High-Temperature (HPHT) Method

The HPHT method is the original process for creating synthetic diamonds and is a direct simulation of the natural geological process.

The Goal: Simulating the Earth's Mantle

The objective of the HPHT process is to replicate the extreme environment where natural diamonds form, roughly 100 miles below the Earth's surface. This involves generating immense pressure and incredibly high temperatures.

The Equipment: The HPHT Press

The central piece of equipment is an HPHT press. These massive machines are capable of generating sustained pressures exceeding 800,000 pounds per square inch (5.5 GPa) and temperatures over 2,700°F (1500°C).

The Process: Carbon, Metal, and a Seed

Inside the press, a source of carbon (such as graphite) is placed in a capsule along with a metallic catalyst and a tiny, pre-existing diamond crystal known as a diamond seed.

Under the intense heat and pressure, the metal catalyst melts and dissolves the carbon source. The carbon atoms then migrate through the molten metal and crystallize onto the cooler diamond seed, slowly growing a new, larger synthetic diamond.

The Chemical Vapor Deposition (CVD) Method

CVD is a more recent innovation that approaches diamond creation from a completely different angle. Instead of simulating brute force, it focuses on precise, additive manufacturing at the atomic level.

The Goal: Building a Diamond Layer by Layer

The objective of the CVD process is not to crush carbon into a diamond, but to "grow" one by depositing carbon atoms onto a substrate in a highly controlled, low-pressure environment.

The Equipment: The CVD Reactor

This process takes place inside a vacuum chamber known as a CVD reactor. The chamber is designed to maintain a near-vacuum while precisely controlling the introduction of gases and the application of energy.

The Process: Gas, Plasma, and Growth

A thin slice of a diamond seed is placed inside the reactor. Carbon-rich gases, typically methane, are then introduced into the chamber at very low pressure.

Energy, often in the form of microwaves, is used to heat the gas into a plasma. This breaks the gas molecules apart, freeing carbon atoms. These atoms then settle down onto the diamond seed plate, building up the diamond crystal layer by atomic layer.

Understanding the Trade-offs

The manufacturing method is not just a technical detail; it defines the diamond's growth characteristics and leaves markers that gemological labs can detect.

HPHT Characteristics

Diamonds produced by the HPHT method are grown in a molten metal flux. As a result, they can sometimes contain tiny metallic inclusions, which are a key identifier for gemologists. HPHT is also frequently used as a secondary treatment to improve the color of both natural and lab-grown diamonds.

CVD Characteristics

CVD diamonds grow in distinct layers, which can create unique internal strain patterns. They are grown without the presence of nitrogen that is common in natural diamonds, giving them exceptional purity. Advanced spectroscopic tools can easily identify the signatures of CVD growth, such as specific types of fluorescence.

Why Two Methods?

HPHT is a mature technology effective for producing both industrial and gem-quality diamonds. CVD has gained prominence for gem-quality stones because it requires lower pressure and energy, offering a path to greater scalability and the ability to produce large, high-clarity diamonds that may only require simple post-growth treatments.

The Core Principle of Synthetic Diamond Creation

Ultimately, both methods overcome the same fundamental energy barrier to turn carbon into diamond. The equipment simply reflects the two different pathways chosen to solve that single scientific challenge.

- If the goal is to mimic natural formation: The HPHT press is used to apply immense pressure and heat to a carbon source, forcing it to crystallize onto a seed.

- If the goal is to build a diamond atom by atom: The CVD reactor is used to break down carbon-rich gas into a plasma and deposit the free carbon atoms onto a seed plate.

- If the goal is gem-quality production: Both methods are effective, but CVD has become a leading choice for its scalability and ability to produce large, high-purity stones.

By mastering these two distinct technological paths, we have gained the ability to create one of nature's most coveted materials on demand.

Summary Table:

| Method | Core Equipment | Process Summary | Key Characteristics |

|---|---|---|---|

| HPHT | High-Pressure, High-Temperature Press | Mimics Earth's mantle using extreme pressure & heat on a carbon source and seed. | Can contain metallic inclusions; often used for color treatment. |

| CVD | Chemical Vapor Deposition Reactor | Grows diamond atom-by-atom from a carbon-rich gas plasma onto a seed plate. | High purity, distinct layer growth, scalable for large, gem-quality stones. |

Ready to incorporate synthetic diamond technology into your research or production? KINTEK specializes in providing high-quality lab equipment and consumables for advanced material synthesis. Whether your project requires the robust power of an HPHT system or the precise control of a CVD reactor, our experts can help you select the ideal solution for your laboratory's needs. Contact our team today to discuss how we can support your innovation in diamond creation.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the high temperature for CVD? Unlock Optimal Film Quality for Your Lab

- What is chemical Vapour deposition method? A Guide to High-Purity Thin Film Fabrication

- What are the advantages of cold-wall CVD for graphene growth? Precision Heating for High-Mobility Monolayers

- What is CVD in manufacturing? A Guide to High-Purity Material Deposition

- What are the factors affecting the quality of film formed via sputtering? Achieve Superior Thin Film Coatings

- What are the applications of sputter deposition? Achieve Superior Thin Films for Electronics and Optics

- What is chemical vapour deposition of graphene synthesis? A Guide to Scalable, High-Quality Graphene Production

- How does Thermal LCVD work? Mastering Precision Localized Deposition and Direct Micro-Fabrication