Ultimately, your final decision on a lab freeze dryer should be guided by a comprehensive assessment of your specific applications, sample characteristics, required throughput, and long-term operational costs. It is a balancing act between matching the machine's technical specifications to your scientific needs and ensuring the investment is practical for your budget and facility.

Choosing a freeze dryer is not about finding the single "best" machine, but about identifying the right machine for your specific samples and workflow. The most critical error is to mismatch the equipment's capabilities—particularly its cold trap temperature—with the materials you intend to dry.

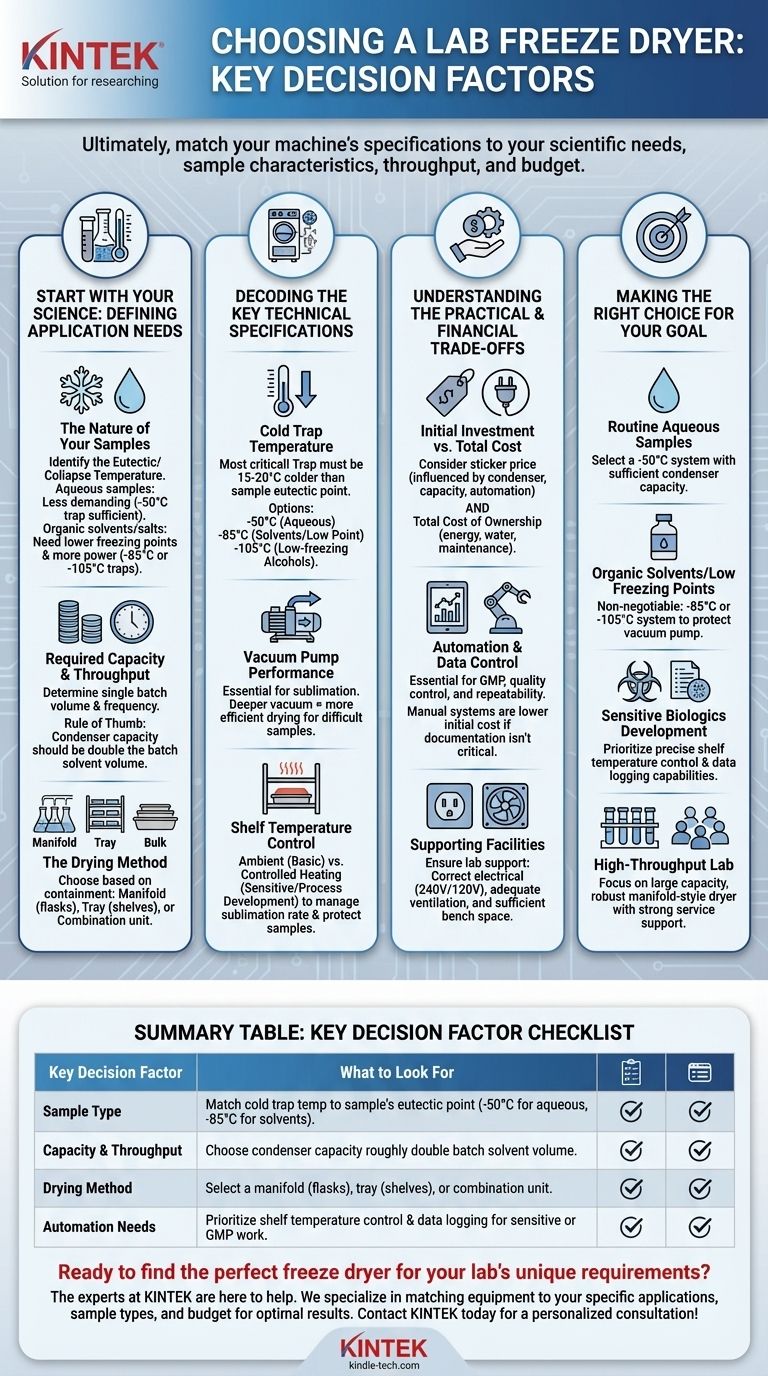

Start with Your Science: Defining Application Needs

Before looking at any hardware, you must first define the problem you are trying to solve. The nature of your samples and your experimental goals will dictate the necessary technical specifications.

The Nature of Your Samples

The most important factor is the composition of your samples. The freezing point of your material, known as the eutectic or collapse temperature, is the critical data point.

Materials with a high freezing point, such as those with a primarily water (aqueous) base, are less demanding.

Samples containing organic solvents (like acetonitrile or ethanol) or salts have much lower freezing points and require more powerful systems to process effectively.

Required Capacity and Throughput

Consider both the volume of a single batch and how frequently you will need to run the system. This determines the required condenser capacity, which is measured in liters.

A condenser must be able to hold all the sublimated solvent from your batch as ice before it needs to be defrosted. A good rule of thumb is to choose a condenser with a capacity roughly double your expected batch solvent volume.

The Drying Method

How your samples are contained is also a key consideration. Will you be drying in flasks, in vials on shelves, or in bulk pans?

This determines whether you need a manifold dryer (with ports for flasks), a tray dryer (with shelves inside a chamber), or a combination unit.

Decoding the Key Technical Specifications

Once you understand your scientific needs, you can translate them into the core performance indicators of a freeze dryer.

Cold Trap Temperature

This is the single most critical specification. The cold trap's job is to condense and freeze the solvent vapor coming off your samples, protecting the vacuum pump.

The trap must be at least 15-20°C colder than your sample's eutectic/collapse temperature to work efficiently.

- -50°C traps are suitable for aqueous samples and some solvents with high freezing points.

- -85°C traps are necessary for samples with low eutectic points or those containing most common organic solvents.

- -105°C traps are required for samples containing low-freezing-point alcohols, like ethanol.

Vacuum Pump Performance

The vacuum pump removes air from the system, allowing the frozen solvent in your samples to turn directly into a vapor (sublimation) at a low temperature.

The ultimate vacuum level of the pump determines how efficiently this process occurs. A deeper vacuum is essential for difficult-to-dry samples and for achieving faster results.

Shelf Temperature Control

For basic applications, uncontrolled "ambient" shelves are sufficient.

However, for sensitive biological materials or process development, you need controlled heating shelves. This allows you to carefully manage the rate of sublimation, shortening drying times without damaging the sample's structure.

Understanding the Practical & Financial Trade-offs

A freeze dryer is a significant capital investment with ongoing operational costs. A holistic view is necessary to make a sound financial decision.

Initial Investment vs. Total Cost

The sticker price is influenced primarily by condenser temperature, capacity, and automation features. A -85°C system will cost more than a -50°C system of the same size.

However, you must also consider the total cost of ownership, which includes electricity consumption, potential water usage for cooling, and future maintenance costs.

Automation and Data Control

Modern freeze dryers can offer advanced automation and data logging. These features are not "frills" but essential tools for GMP environments, quality control, or any application where process repeatability is critical.

If your work does not require this level of documentation, you can select a more basic manual system to reduce initial cost.

Supporting Facilities

Ensure your lab can support the machine. This includes having the correct electrical outlets (e.g., 240V vs. 120V), adequate ventilation for the vacuum pump and refrigeration units, and sufficient bench space.

Making the Right Choice for Your Goal

Select features based on your specific requirements to ensure you get a machine that serves your needs without paying for capabilities you will never use.

- If your primary focus is routine drying of simple aqueous samples: A -50°C system with sufficient condenser capacity for your batch sizes is the most economical and effective choice.

- If you work with organic solvents or samples with very low freezing points: A -85°C or -105°C system is non-negotiable to prevent solvent from damaging the vacuum pump.

- If you are developing optimized protocols for sensitive biologics: Prioritize a unit with precise shelf temperature control and data logging capabilities.

- If you run a high-throughput lab with many users and sample types: Focus on a larger capacity, robust manifold-style dryer with a strong service and support plan from the manufacturer.

By first analyzing your scientific application and then matching it to the core technical specifications, you will select a freeze dryer that is a productive and reliable asset for your lab.

Summary Table:

| Key Decision Factor | What to Look For |

|---|---|

| Sample Type | Match cold trap temperature to sample's eutectic point (e.g., -50°C for aqueous, -85°C for solvents). |

| Capacity & Throughput | Choose a condenser capacity roughly double your batch solvent volume. |

| Drying Method | Select a manifold (for flasks), tray (for shelves), or combination unit. |

| Automation Needs | Prioritize shelf temperature control & data logging for sensitive or GMP work. |

Ready to find the perfect freeze dryer for your lab's unique requirements? The experts at KINTEK are here to help. We specialize in matching laboratory equipment like freeze dryers to your specific applications, sample types, and budget. Let us guide you to a solution that ensures reliability, efficiency, and optimal results.

Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What are the main components of a laboratory freeze dryer? A Guide to the 5 Essential Systems

- What are some common drying methods used in laboratories and their drawbacks? Choose the Right Method to Protect Your Samples

- What are some common problems to avoid during freeze drying? Prevent Melt-Back and System Overload

- Why is freeze drying considered more effective than ordinary drying? Preserve Structure, Nutrients & Flavor

- What problems should be avoided when using a lyophilizer? Prevent Product Collapse and Equipment Overload