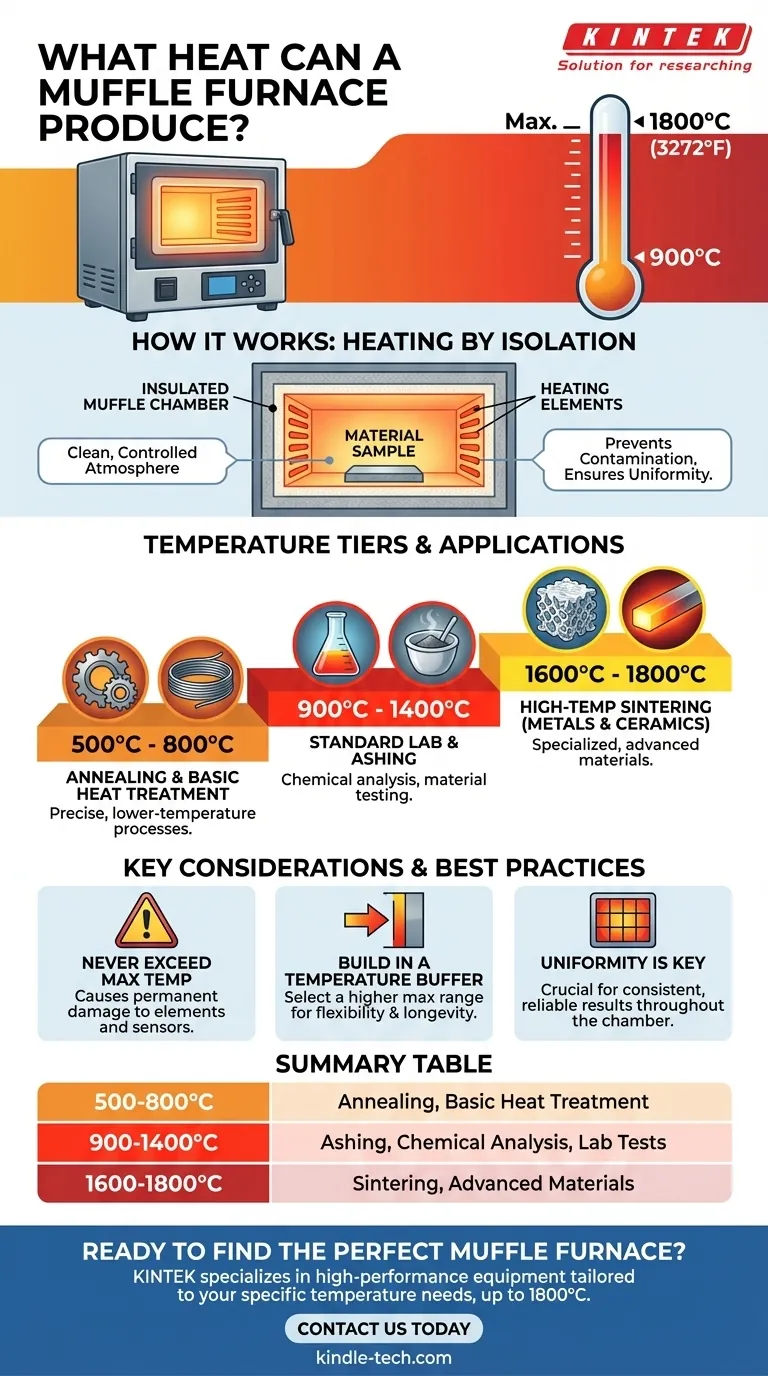

In short, a muffle furnace can produce extremely high temperatures, typically ranging from 900°C up to a maximum of 1800°C (3272°F). While some general-purpose models operate at lower maximums, high-temperature units are specifically designed for applications like sintering, ashing, and advanced materials testing that demand this intense heat.

The key takeaway is that a muffle furnace's temperature capability is defined by its specific design and intended application. Selecting the right furnace involves matching its temperature range to your precise procedural needs, not just seeking the highest possible value.

How a Muffle Furnace Achieves High, Controlled Heat

The Core Principle: Heating by Isolation

A muffle furnace's primary design feature is its "muffle"—an insulated inner chamber that separates the material being heated from the heating elements and any combustion byproducts.

This isolation is critical. It ensures the sample is heated in a clean, controlled atmosphere, preventing contamination and allowing for precise, uniform temperature management. Modern designs excel at rapid heating and cooling cycles within these self-contained cabinets.

Understanding the Temperature Tiers

Not all muffle furnaces are created equal. They are generally built to serve different temperature ranges based on the tasks they are designed to perform.

- General Heat Treatment & Annealing: This range typically falls between 500°C and 800°C. These processes require precise heat but do not need the extreme temperatures of materials science.

- Standard Laboratory Applications: Many common lab furnaces operate in the 900°C to 1400°C range. This is suitable for many ashing procedures, chemical analysis, and material tests.

- High-Temperature Sintering: For advanced applications like sintering metals and ceramics, furnaces must reach the 1600°C to 1800°C range. These are specialized, robustly built units.

Key Considerations and Best Practices

Never Exceed the Maximum Rated Temperature

This is the most critical operating rule. Pushing a furnace beyond its specified maximum temperature can cause permanent damage to the heating elements, insulation, and control thermocouples.

Operating at the absolute maximum for extended periods also shortens the lifespan of the components.

Build in a Temperature Buffer

When selecting a furnace, it is wise to choose a model with a maximum temperature that comfortably exceeds your highest required temperature.

This provides two key advantages. First, it ensures the furnace is not constantly strained at its operational limit. Second, it offers the flexibility to accommodate future applications that may require more heat.

Uniformity is as Important as Peak Temperature

Achieving a high temperature is only half the battle. A quality muffle furnace also provides excellent temperature uniformity throughout the chamber.

This ensures that your entire sample is subjected to the same thermal conditions, which is essential for obtaining reliable and repeatable results in scientific and industrial processes.

Making the Right Choice for Your Goal

When selecting a muffle furnace, your decision should be guided entirely by your specific application.

- If your primary focus is annealing or basic heat treating: A furnace with a maximum temperature around 1100°C or 1200°C is typically sufficient and more cost-effective.

- If your primary focus is sintering advanced ceramics or high-temperature ashing: You must invest in a high-temperature model rated for 1700°C or 1800°C.

- If your primary focus is operational flexibility for a multi-use lab: Select a furnace with a higher range than you currently need to accommodate a wider variety of future projects.

Ultimately, choosing the correct muffle furnace is about precisely matching the tool's capabilities to your technical requirements.

Summary Table:

| Temperature Range | Common Applications | Key Considerations |

|---|---|---|

| 500°C - 800°C | Annealing, Basic Heat Treatment | Suitable for precise, lower-temperature processes |

| 900°C - 1400°C | Ashing, Chemical Analysis, Material Testing | Standard for most laboratory applications |

| 1600°C - 1800°C | Sintering Metals & Ceramics, Advanced Materials | Requires specialized, high-temperature units |

Ready to find the perfect muffle furnace for your lab's specific temperature needs?

At KINTEK, we specialize in providing high-performance lab equipment tailored to your applications—whether you require standard heat treatment or advanced sintering up to 1800°C. Our experts will help you select a furnace with the right temperature range, uniformity, and durability for reliable results.

Contact us today to discuss your requirements and get a personalized solution!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What critical environmental conditions does a muffle furnace provide for NaSICON? Optimize Your Solid Electrolyte Synthesis

- What is a laboratory oven? A Guide to Precision Heating for Scientific Applications

- How do high-precision high-temperature furnaces assist in biochar-cement compatibility? Optimize Hydration & Strength

- Why is a high-temperature muffle furnace required for the calcination treatment of TNTAs? Unlock Peak Performance

- How is a high-temperature muffle furnace utilized in the solid-phase synthesis of Beta-Al2O3? Boost Ionic Conductivity

- What is an oven furnace? Achieve Precise, Uniform Heat for Industrial & Lab Applications

- What roles do the two-step sintering processes play in high-temperature furnaces? Mastering High-Density Magnesia.

- What is the calcination process? A Guide to Thermal Purification and Material Transformation