In essence, a freeze dryer is a specialized machine that removes water from a substance to preserve it. Unlike simple dehydration which uses heat, a freeze dryer first freezes the material and then turns the frozen ice directly into a vapor, completely bypassing the liquid phase. This process, known as lyophilization, perfectly preserves the material's structure, chemistry, and biological properties.

The core function of a freeze dryer is to achieve preservation through sublimation. By freezing a material and placing it under a deep vacuum, it allows ice to turn directly into vapor, gently removing water without the damaging effects of heat.

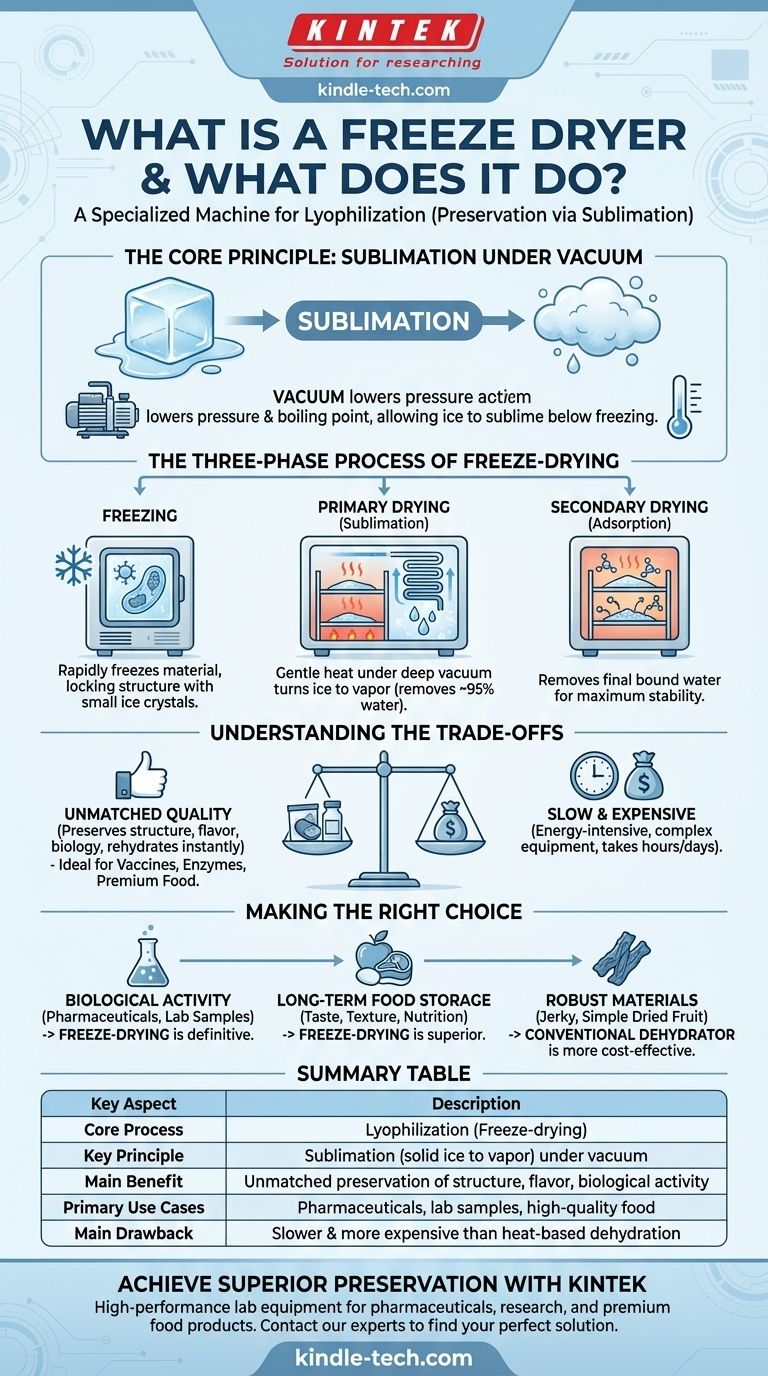

The Core Principle: Sublimation Under Vacuum

To understand a freeze dryer, you must first understand the physics it exploits. The entire process hinges on a phenomenon called sublimation.

What is Sublimation?

Sublimation is the direct transition of a substance from a solid state to a gas state, without ever becoming a liquid.

The most common example of this is dry ice (solid carbon dioxide). At room temperature and pressure, it doesn't melt into a puddle; it turns directly into a gas.

Freeze-drying forces water to do the exact same thing.

Why is a Vacuum Necessary?

A vacuum pump is used to dramatically lower the pressure inside the freeze dryer's chamber.

Lowering the pressure also lowers the temperature at which water boils and sublimates. Under a deep vacuum, ice can turn into water vapor at temperatures well below freezing, ensuring the material itself never thaws.

The Three-Phase Process of Freeze-Drying

Lyophilization is a meticulous, multi-stage process. Each phase serves a distinct and critical purpose.

Phase 1: Freezing

The first step is to rapidly freeze the material. This is crucial because it locks the material's physical structure in place.

Quick freezing creates small ice crystals, which cause less damage to the cellular structure of the material you are trying to preserve.

Phase 2: Primary Drying (Sublimation)

Once frozen, the material is placed under a deep vacuum. A small, controlled amount of heat is then gently applied to the shelves holding the material.

This added energy gives the frozen water molecules just enough power to break free and turn into vapor (sublimate). This vapor is then drawn away and collected on a freezing-cold condenser coil, trapping it as ice. This phase removes about 95% of the water.

Phase 3: Secondary Drying (Adsorption)

The final phase removes the last traces of water molecules that are chemically bound to the material.

The temperature is raised slightly higher (still often below room temperature) and the vacuum pressure may be lowered further. This breaks the bonds between the material and the remaining water, ensuring maximum long-term stability of the final product.

Understanding the Trade-offs and Applications

While incredibly effective, freeze-drying is not a universal solution. It involves a clear trade-off between preservation quality and operational cost.

The Benefit: Unmatched Preservation Quality

Because it avoids the liquid phase and high heat, freeze-drying is exceptionally gentle. It is the gold standard for preserving delicate biological materials like vaccines, enzymes, and cell cultures.

When applied to food, it preserves the original shape, color, flavor, and nutritional content far better than traditional dehydration, and the final product rehydrates almost instantly.

The Drawback: A Slow and Expensive Process

The primary disadvantage is that freeze-drying is a very slow, energy-intensive process that can take many hours or even days to complete.

The required equipment—specifically the powerful refrigeration and vacuum systems—is complex and expensive to purchase and operate compared to a simple food dehydrator.

Making the Right Choice for Your Goal

Understanding the core function of a freeze dryer allows you to determine if it's the appropriate tool for your specific preservation needs.

- If your primary focus is preserving biological activity: Freeze-drying is the definitive choice for materials like pharmaceuticals, lab samples, or enzymes where chemical structure is paramount.

- If your primary focus is high-quality, long-term food storage: Freeze-drying provides superior taste, texture, and nutritional retention compared to any other method, making it ideal for archival purposes or premium products.

- If your primary focus is simply removing water from a robust material: A conventional dehydrator using heat is a far more cost-effective and faster solution for things like jerky or simple dried fruit.

By mastering the transition from solid to gas, freeze-drying offers the most faithful method for preserving delicate materials for the future.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Process | Lyophilization (Freeze-drying) |

| Key Principle | Sublimation (solid ice to vapor) under vacuum |

| Main Benefit | Unmatched preservation of structure, flavor, and biological activity |

| Primary Use Cases | Pharmaceuticals, laboratory samples, high-quality food preservation |

| Main Drawback | Slower and more expensive than heat-based dehydration |

Ready to achieve superior preservation for your laboratory materials?

KINTEK specializes in high-performance lab equipment, including freeze dryers designed for precision and reliability. Whether you are preserving sensitive pharmaceuticals, critical research samples, or developing premium food products, our solutions help you maintain integrity and extend shelf life.

Contact our experts today to find the perfect freeze-drying solution for your specific needs and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- How much can proper freeze drying reduce drying times? Cut Drying Time by Up to 30%

- What are the key advantages of using freeze dryers? Achieve Unmatched Preservation for Your Materials

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- What precautions should be taken when using a laboratory freeze dryer? Essential Steps for Reliable Lyophilization

- How does cooling rate affect freeze dryer performance? Unlock Faster, More Reliable Lyophilization