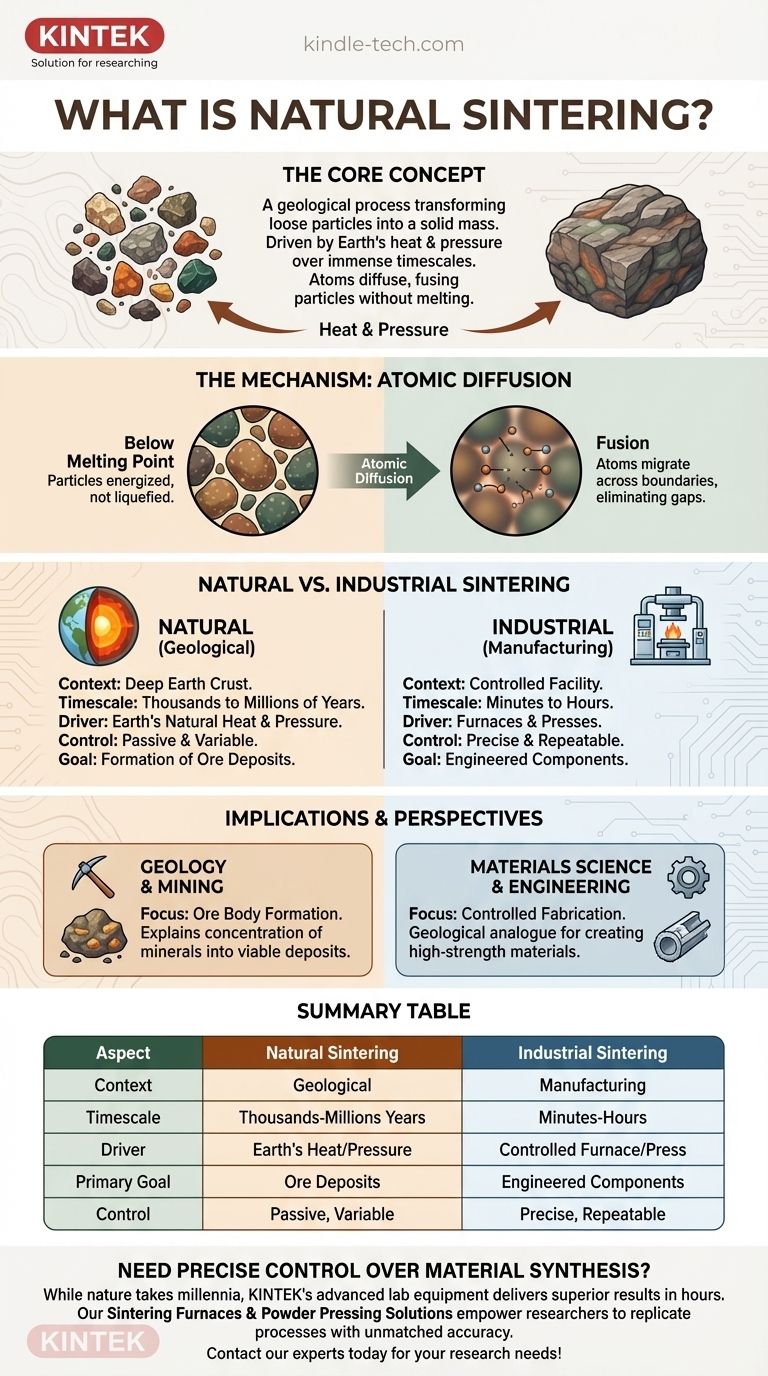

At its core, natural sintering is a geological process that transforms loose mineral particles into a solid, high-density mass. Driven by the Earth's natural heat and pressure over immense timescales, atoms diffuse across particle boundaries, fusing them together to form ore deposits without ever melting the material.

The critical distinction is not the physical mechanism, but the context. While both natural and industrial sintering rely on atomic diffusion to fuse particles, one is a slow, passive geological event, and the other is a fast, controlled manufacturing technique.

The Fundamental Mechanism: How Sintering Works

A Process Without Melting

Sintering compacts and forms a solid mass of material using heat and pressure. Crucially, the temperature remains below the material's melting point.

Instead of liquefying, the particles are energized just enough for their atoms to become mobile. This technique is essential for processing materials with extremely high melting points, such as tungsten.

The Power of Atomic Diffusion

The scientific principle behind sintering is atomic diffusion. When heated, atoms gain enough energy to migrate from their own particle and cross the boundary into an adjacent one.

This migration effectively blurs the lines between individual particles. They fuse together at a microscopic level, eliminating the gaps between them and creating a single, dense, and solid piece.

Natural vs. Industrial Sintering

The Geological Context (Natural)

Natural sintering occurs deep within the Earth's crust over thousands or millions of years. The sustained, moderate heat and immense pressure from overlying rock and geological activity provide the energy for the process.

This is a fundamental mechanism in the formation of many mineralogical deposits. It is how loose sediments or mineral grains are transformed into the solid, high-density ore that is extracted through mining.

The Manufacturing Context (Industrial)

Industrial sintering is a deliberate, highly controlled, and rapid process. Powdered materials are placed in a mold and subjected to high heat and/or pressure in a furnace or press.

This allows engineers to create strong, precisely shaped components from materials that are difficult or impossible to melt and cast. It is a cornerstone of powder metallurgy and ceramics manufacturing.

Understanding the Implications

Why Natural Sintering Matters

Understanding natural sintering is crucial for geologists and mining engineers. It explains how valuable minerals become concentrated and consolidated into economically viable ore bodies.

The process is responsible for the physical characteristics of many types of rock and mineral deposits, influencing their density, porosity, and strength.

The Trade-off: Control vs. Scale

The primary trade-off is control. The natural process is passive and uncontrolled, resulting in complex and variable geological formations.

The industrial process, by contrast, offers complete control over temperature, pressure, and time. This precision allows for the engineering of materials with specific, repeatable properties for advanced applications.

How to Apply This Knowledge

The lens through which you view sintering depends entirely on your field.

- If your primary focus is Geology or Mining: Regard natural sintering as the fundamental process that transforms loose mineral grains into dense, valuable ore bodies over geological time.

- If your primary focus is Materials Science or Engineering: See natural sintering as the geological analogue to the controlled industrial process used to fabricate high-strength components from powdered materials.

Ultimately, understanding this natural phenomenon provides a powerful foundation for appreciating the controlled engineering of modern materials.

Summary Table:

| Aspect | Natural Sintering | Industrial Sintering |

|---|---|---|

| Context | Geological process | Manufacturing technique |

| Timescale | Thousands to millions of years | Minutes to hours |

| Driver | Earth's heat and pressure | Controlled furnace/press |

| Primary Goal | Formation of ore deposits | Creation of engineered components |

| Control | Passive and variable | Precise and repeatable |

Need precise control over your material synthesis? While nature takes millennia, KINTEK's advanced lab equipment delivers superior results in hours. Our sintering furnaces and powder pressing solutions empower geologists and materials scientists to replicate and study these processes with unmatched accuracy. Contact our experts today to find the perfect equipment for your research or quality control needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the most efficient and environment-friendly refrigerant fluids used in Ultra Freezers? Choose Natural Hydrocarbons for a Greener Lab

- What is the magnetic field sputtering of DC magnetron? Boost Deposition Rates & Film Quality

- Why must PEO and lithium salt raw materials be pre-treated in a vacuum drying oven? Ensure Battery Stability

- What is the significance of using a needle valve to inject pure oxygen? Master Precise Oxidative Leaching Controls

- What is the difference between hot air oven and laboratory incubator? Choose the Right Thermal Instrument

- How to calculate coating thickness? Select the Right Method for Accurate Results

- How do high-precision high-pressure injection pumps contribute to flow-through reactor systems? Expert Insights

- What is meant by sintered glass? A Guide to Its Porous Structure and Uses