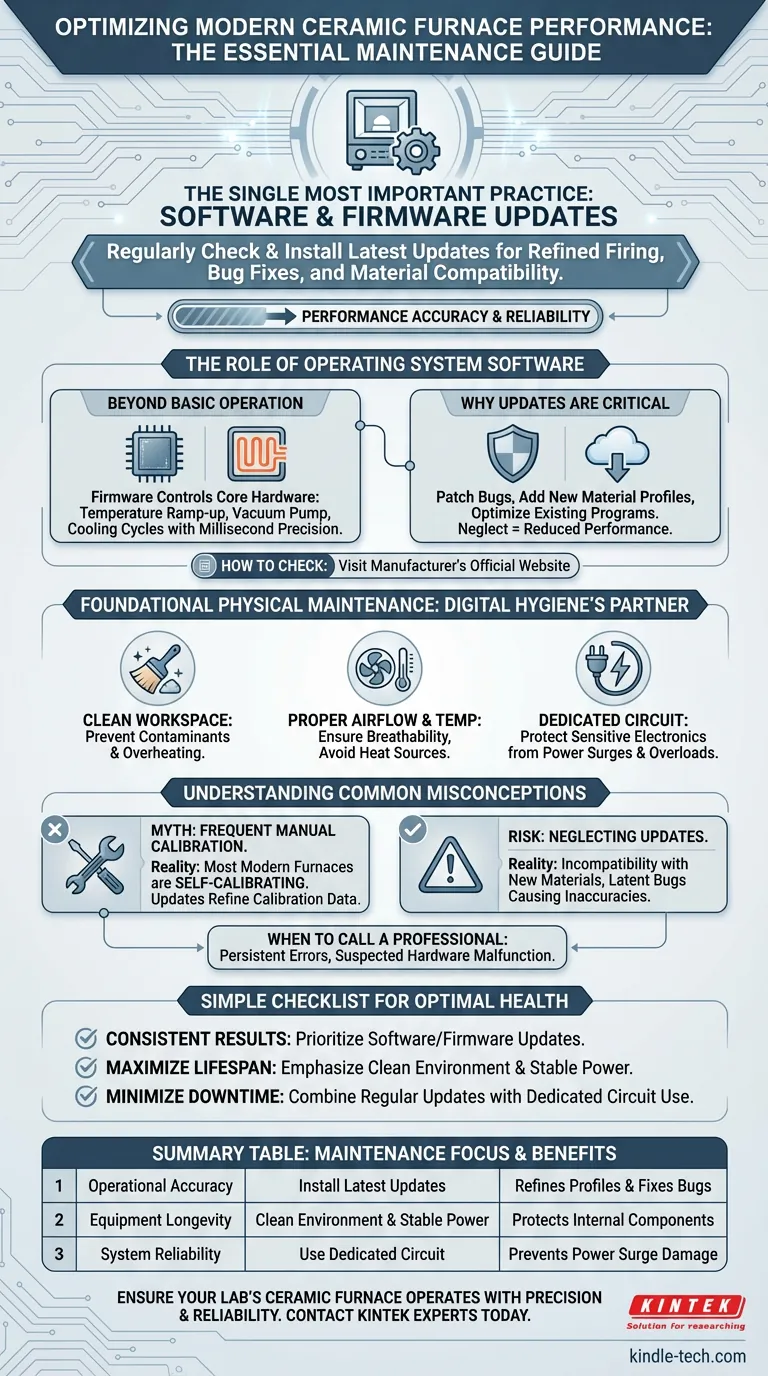

For modern ceramic furnaces, the single most important maintenance practice for the operating system is to periodically check for and install the latest firmware and software updates. Manufacturers release these updates to refine firing parameters, fix bugs, and ensure compatibility with new materials, making it a critical step for maintaining accuracy and performance.

While software updates are the key to maintaining a furnace's operational intelligence, true long-term reliability depends on pairing this digital hygiene with foundational physical maintenance, including a clean environment and a stable power supply.

The Role of Software in Modern Furnace Performance

A modern ceramic furnace is more than just a heating element; it's a precision instrument run by sophisticated software. This software dictates every critical step of the firing process.

Beyond Basic Operation

The furnace's firmware is the embedded operating system that controls the core hardware. It manages the heating element's temperature ramp-up, the vacuum pump engagement, and cooling cycles with millisecond precision.

Why Updates Are Critical

Manufacturers release updates for several key reasons: to patch bugs that could cause firing errors, to add firing profiles for new ceramic materials entering the market, and to optimize the performance of existing programs. Neglecting these updates means you are not getting the full performance and accuracy from your equipment.

How to Check for Updates

The most reliable method is to visit the manufacturer's official website. They typically have a support or downloads section where you can find the latest software version for your specific furnace model, along with instructions for installation.

Foundational Maintenance: The Physical Environment

Digital maintenance is only effective if the physical hardware is properly cared for. The environment in which the furnace operates has a direct impact on its longevity and performance.

The Importance of a Clean Workspace

Dust and debris are the enemies of high-tech equipment. Keeping the furnace and the area around it clean prevents contaminants from interfering with mechanical parts or causing electronic components to overheat.

Ensuring Proper Airflow and Temperature

Your furnace needs to breathe. Ensure it is placed in a temperature-controlled area with good airflow, away from the heat and dust generated by other lab activities like casting or grinding. This prevents overheating and extends the life of internal components.

The Non-Negotiable Dedicated Circuit

A modern furnace contains sensitive electronics that are highly vulnerable to power surges and voltage drops. It is highly recommended to plug the unit into a dedicated electrical outlet to protect it from circuit overloads caused by other equipment on the same line.

Understanding Common Misconceptions

To properly maintain your furnace, it's important to separate modern best practices from outdated assumptions.

The Myth of Frequent Manual Calibration

Unlike older models, most modern porcelain furnaces are largely self-calibrating. The internal software and sensors are designed to maintain accuracy over time. This makes manufacturer firmware updates even more crucial, as they often contain refined calibration data.

The Risk of Neglecting Updates

Skipping software updates can lead to tangible problems. Your furnace might become incompatible with the manufacturer's parameters for a new ceramic you want to use, or a latent bug could cause a subtle firing inaccuracy that compromises restorations.

When to Call a Professional

User maintenance includes cleaning, updating software, and ensuring a proper environment. However, if you experience persistent errors or suspect a hardware malfunction, a professional inspection is necessary for internal cleaning or component replacement.

A Simple Checklist for Optimal Furnace Health

Use these guidelines to align your maintenance strategy with your primary goals.

- If your primary focus is consistent, accurate firing results: Prioritize keeping your furnace's software and firmware consistently updated to match the latest material parameters.

- If your primary focus is maximizing equipment lifespan: Emphasize maintaining a clean, temperature-controlled environment with stable airflow and a dedicated power source.

- If your primary focus is minimizing unexpected downtime: Combine regular software checks with the unwavering use of a dedicated electrical circuit to prevent both software and hardware failures.

Following these simple but critical maintenance habits will protect your investment and ensure your furnace performs reliably for years to come.

Summary Table:

| Maintenance Focus | Key Practice | Primary Benefit |

|---|---|---|

| Operational Accuracy | Install latest firmware/software updates | Refines firing profiles & fixes bugs |

| Equipment Longevity | Maintain clean environment & stable power | Protects sensitive internal components |

| System Reliability | Use a dedicated electrical circuit | Prevents damage from power surges |

Ensure your lab's ceramic furnace operates with precision and reliability.

At KINTEK, we understand that your laboratory's success depends on the consistent performance of your equipment. Our expertise in lab equipment, including ceramic furnaces, means we can provide you with the support and consumables needed to maintain peak operation.

Don't let outdated software or improper maintenance compromise your results. Contact our experts today to discuss how we can help you optimize your furnace's performance and extend its lifespan.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control