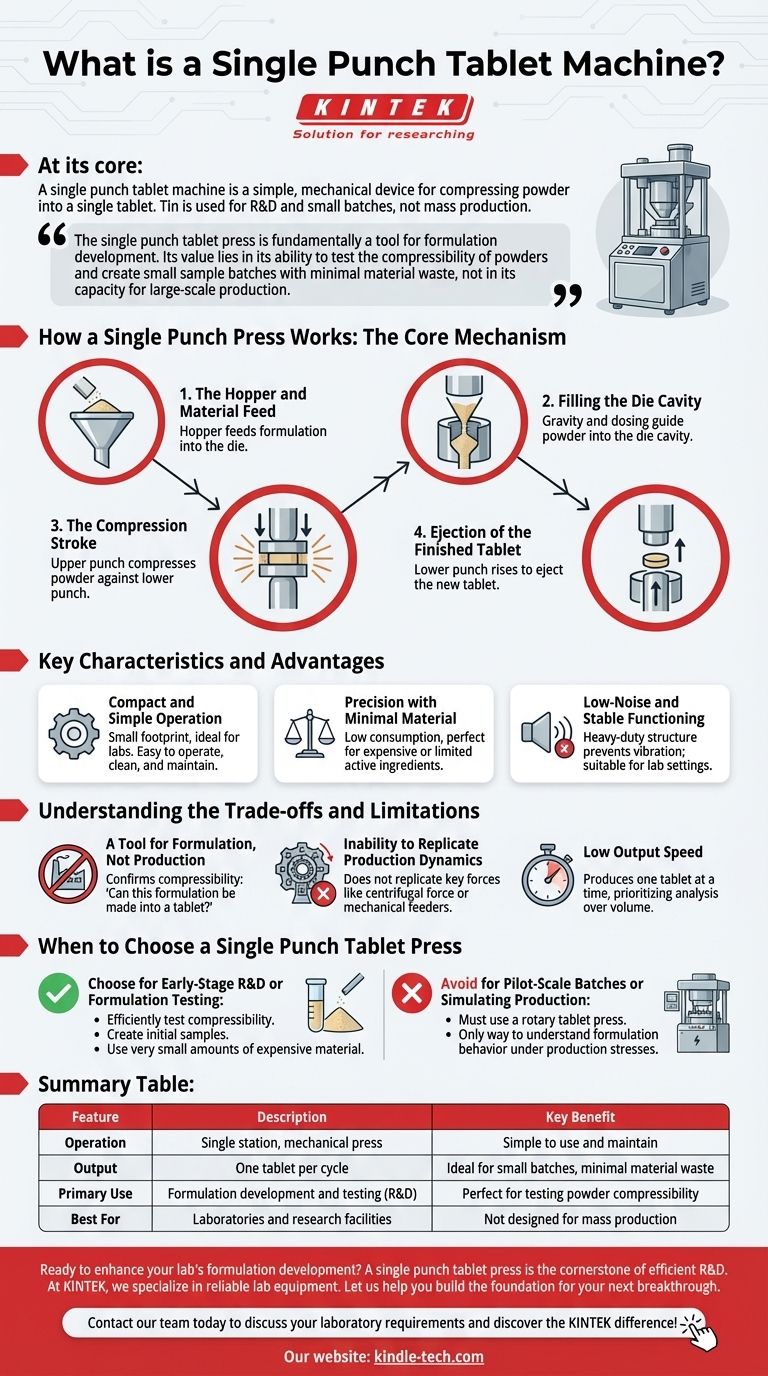

At its core, a single punch tablet machine is a simple, mechanical device used to compress powder into a single, uniform tablet. Also known as an eccentric press or single station press, it is designed for small-batch production, research and development (R&D), and laboratory testing rather than mass manufacturing.

The single punch tablet press is fundamentally a tool for formulation development. Its value lies in its ability to test the compressibility of powders and create small sample batches with minimal material waste, not in its capacity for large-scale production.

How a Single Punch Press Works: The Core Mechanism

The operation of a single punch press is a straightforward, cyclical process involving a single set of tooling—an upper punch, a lower punch, and a die.

The Hopper and Material Feed

All raw material, in powder or granular form, is held in a funnel-shaped container called the hopper. This component feeds the formulation into the die for compression.

Filling the Die Cavity

Gravity and a dosing mechanism guide a precise amount of powder from the hopper into the die cavity. This cavity is the mold that defines the final shape and size of the tablet.

The Compression Stroke

The upper punch descends with significant force into the die cavity, compressing the powder against the stationary lower punch. This immense pressure forces the powder particles to bond together, forming a solid tablet.

Ejection of the Finished Tablet

After compression, the upper punch retracts. The lower punch then rises within the die, pushing the newly formed tablet out of the cavity, where it is swept away for collection.

Key Characteristics and Advantages

The design of a single punch press is optimized for specific, non-production environments. Its primary benefits stem from its simplicity and scale.

Compact and Simple Operation

These machines are characterized by their small footprint, making them ideal for laboratory benchtops. Their mechanical simplicity makes them easy to operate, clean, and maintain.

Precision with Minimal Material

A key advantage is their low consumption of material. When working with expensive active ingredients or limited test batches, the ability to produce tablets with a high precision of fill is invaluable.

Low-Noise and Stable Functioning

Most single punch presses are built with a heavy-duty structure to avoid vibration during operation. This, combined with their simple mechanical action, results in very low-noise performance suitable for a lab setting.

Understanding the Trade-offs and Limitations

While excellent for its intended purpose, the single punch press has critical limitations that make it unsuitable for production-level work. Understanding these trade-offs is essential.

A Tool for Formulation, Not Production

The primary purpose of this machine is to confirm the compressibility of a powder blend. It answers the fundamental question: "Can this formulation be made into a tablet?"

Inability to Replicate Production Dynamics

This is the most significant limitation. A single punch press does not replicate the key forces at play in a high-speed, production-sized rotary press. Critical factors like centrifugal force (which affects die filling) and the behavior of mechanical feeders are absent.

Low Output Speed

By its very nature, producing one tablet at a time results in a very low output. This is a deliberate design trade-off that prioritizes material conservation and analysis over volume.

When to Choose a Single Punch Tablet Press

Selecting the right equipment depends entirely on your project's goal.

- If your primary focus is early-stage R&D or formulation testing: This is the ideal machine. It allows you to efficiently test compressibility and create initial samples using very small amounts of expensive material.

- If your primary focus is pilot-scale batches or simulating production: You must use a rotary tablet press. This is the only way to understand how your formulation will behave under the mechanical stresses and high speeds of a true manufacturing environment.

Ultimately, the single punch press is an indispensable tool for foundational research, providing the critical data needed before you can confidently scale to larger, more complex machinery.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Operation | Single station, mechanical press | Simple to use and maintain |

| Output | One tablet per cycle | Ideal for small batches, minimal material waste |

| Primary Use | Formulation development and testing (R&D) | Perfect for testing powder compressibility |

| Best For | Laboratories and research facilities | Not designed for mass production |

Ready to enhance your lab's formulation development?

A single punch tablet press is the cornerstone of efficient R&D, allowing you to test compressibility and create precise samples with minimal material waste. At KINTEK, we specialize in providing reliable lab equipment, including single punch presses, to meet your research and development needs.

Let us help you build the foundation for your next breakthrough. Our experts can guide you to the right equipment for your specific application.

Contact our team today to discuss your laboratory requirements and discover the KINTEK difference!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Automatic Laboratory Heat Press Machine

People Also Ask

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production

- What are the different parts of a single punch tablet machine? The Core Components Explained

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- What are the different pill presses? Choose the Right Machine for Your Lab or Production Scale

- What is tablet pressing in pharmaceutical industry? The Core Process for Producing Solid Oral Dosage Forms