In the context of high-precision polishing, a stainless steel micro spatula is a specialized tool used for the careful dispensing of powdered polishing materials, such as alumina powder. Its purpose is to transfer small, controlled quantities of powder onto a polishing cloth to create a slurry, ensuring the process is both precise and free from contamination.

The true function of a micro spatula extends beyond simple scooping; it is a critical instrument for maintaining the purity of your polishing process. Failure to handle it correctly introduces contaminants that can compromise or completely ruin the surface you are trying to perfect.

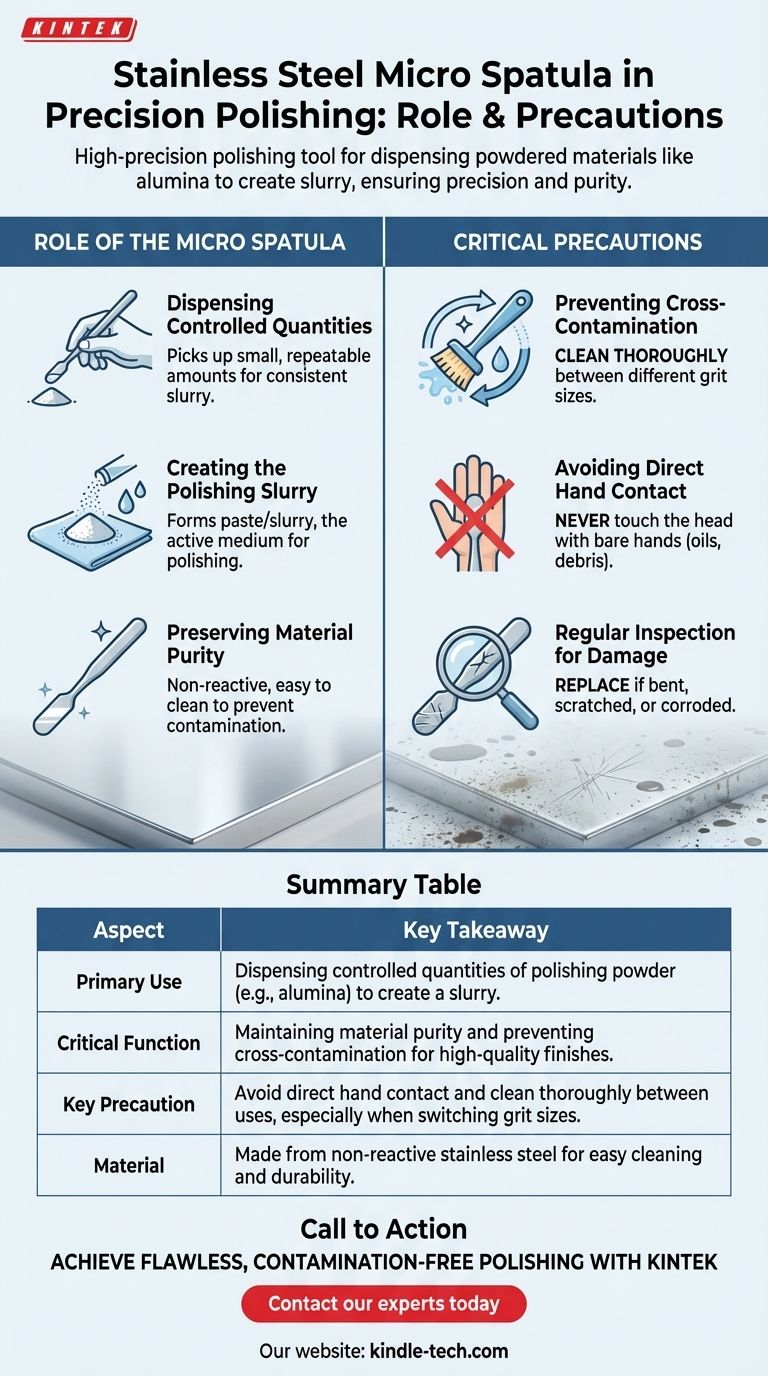

The Role of the Micro Spatula in Precision Polishing

A micro spatula is the first step in a chain of events that dictates the final quality of a polished surface. Its correct use ensures the entire process starts on a foundation of control and purity.

Dispensing Controlled Quantities

The small size of the spatula head allows you to pick up and dispense very small, repeatable amounts of polishing powder. This control is essential for creating a polishing slurry with the correct consistency.

Creating the Polishing Slurry

The process begins by using the spatula to sprinkle a small quantity of powder, like alumina, onto the polishing cloth. This powder is then typically moistened with distilled water to form a paste or slurry, which is the active medium for polishing.

Preserving Material Purity

Stainless steel is used because it is largely non-reactive and easy to clean. This ensures that the spatula itself does not introduce metallic or chemical contaminants into the pure polishing powder.

Critical Precautions to Ensure Process Integrity

The value of the micro spatula lies in what it prevents. The following handling precautions are not suggestions; they are requirements for achieving a reliable and high-quality finish.

Preventing Cross-Contamination

You must thoroughly clean the spatula when switching between different materials, especially between different grit sizes of polishing powder. Any residual coarse particles will create scratches during a fine polishing step, defeating the entire purpose of the process.

Avoiding Direct Hand Contact

Never touch the head of the spatula with your bare hands. Oils, salts, and microscopic debris from your skin can easily transfer to the polishing powder, contaminating the slurry and potentially reacting with the surface of your sample.

Regular Inspection for Damage

A spatula that is bent, scratched, or corroded must be replaced immediately. Surface imperfections can trap old polishing material, making the spatula impossible to fully clean and turning it into a permanent source of contamination.

Understanding Common Pitfalls

Simply owning the right tool is not enough. Awareness of common mistakes is key to achieving professional-grade results.

The Myth of "Visibly Clean"

A spatula can appear clean to the naked eye but still hold microscopic particles that will ruin your next polishing stage. A proper cleaning protocol involves more than a simple wipe; it may require specific solvents, deionized water, or sonication depending on the required level of cleanliness.

Risk of Inconsistent Slurry

A common error is to use the spatula to dispense an inconsistent or excessive amount of powder. This leads to a poorly formed slurry that polishes unevenly, wasting material and time.

Improper Tool Handling

Resting the spatula head directly on a lab bench or other surface between uses is a direct path to contamination. It should be placed on a clean, dedicated rest or in a holder.

Making the Right Choice for Your Goal

Your specific objective determines which handling protocols are most critical.

- If your primary focus is analytical sample preparation (e.g., for microscopy or electrochemistry): Your absolute priority must be a rigorous cleaning protocol to prevent cross-contamination between polishing stages.

- If your primary focus is achieving a perfectly uniform surface finish: Emphasize using the spatula to dispense consistent, small measures of powder to create a homogenous slurry every time.

- If your primary focus is maintaining a pristine lab environment: Strict handling rules, such as never touching the spatula head and using dedicated holders, are paramount to prevent the spread of contaminants.

Ultimately, mastering the disciplined use of this simple tool is a fundamental step toward achieving repeatable, high-quality polishing results.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Use | Dispensing controlled quantities of polishing powder (e.g., alumina) to create a slurry. |

| Critical Function | Maintaining material purity and preventing cross-contamination for high-quality finishes. |

| Key Precaution | Avoid direct hand contact and clean thoroughly between uses, especially when switching grit sizes. |

| Material | Made from non-reactive stainless steel for easy cleaning and durability. |

Achieve Flawless, Contamination-Free Polishing with KINTEK

Mastering the use of a micro spatula is just one step toward perfect sample preparation. For the complete suite of high-precision tools and consumables that your laboratory deserves—from spatulas and polishing powders to advanced lab equipment—trust KINTEK. We specialize in providing reliable solutions that ensure the integrity and repeatability of your results.

Let us help you perfect your process. Contact our experts today to discuss your specific lab equipment and consumable needs!

Visual Guide

Related Products

- Laboratory Jaw Crusher

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- High Purity Gold Platinum Copper Iron Metal Sheets

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Automatic Laboratory Heat Press Machine

People Also Ask

- Why use a laboratory crushing and sieving system for rice husks? Optimize Hydrolysis for 1mm Particle Size

- What is a jaw crusher for labs? The Essential First Step for Accurate Sample Analysis

- How does a jaw crusher contribute to the primary processing of slate waste? Optimize Your Size Reduction Workflow

- What laboratory apparatus is used for grinding? Match the Right Mill to Your Sample Material

- What is the use of jaw crusher in laboratory? The Essential First Step for Sample Reduction