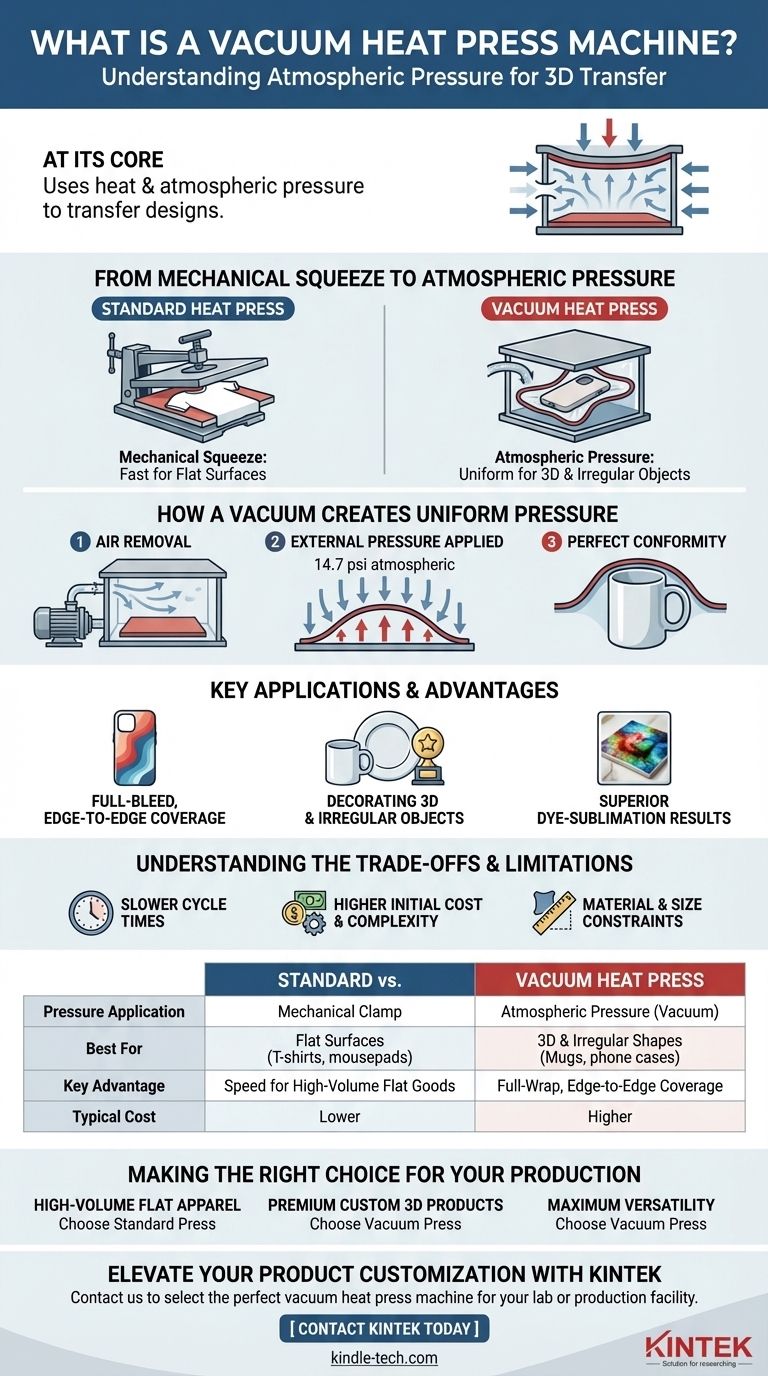

At its core, a vacuum heat press is a specialized machine that uses a combination of heat and atmospheric pressure, created by a vacuum, to transfer designs onto objects. Unlike a standard press that uses a physical clamp, a vacuum press removes air from a chamber, allowing outside air pressure to evenly wrap a transfer sheet around the contours of an item, including complex 3D shapes.

The fundamental difference is how pressure is applied. A standard press uses a direct, mechanical squeeze suitable for flat surfaces, while a vacuum press uses uniform atmospheric pressure to perfectly conform a design to irregular or three-dimensional objects.

From Mechanical Squeeze to Atmospheric Pressure

To understand the value of a vacuum press, we must first understand the limitations of its predecessor. The innovation lies entirely in the method of applying pressure.

The Standard Heat Press

A traditional heat press operates like a high-temperature vise. It has a heated top platen and a stationary bottom platen.

Pressure is applied by physically clamping these two flat surfaces together, squeezing the design transfer against a flat substrate like a t-shirt or a mousepad. This method is fast and effective for two-dimensional items.

The Vacuum Heat Press Innovation

A vacuum heat press replaces the mechanical clamp with a vacuum chamber and a flexible silicone membrane.

The process involves placing the object and its transfer paper inside the chamber. A pump then removes all the air, creating a vacuum.

How a Vacuum Creates Uniform Pressure

By removing the air inside the chamber, a pressure differential is created. The normal atmospheric pressure outside the chamber (approximately 14.7 pounds per square inch at sea level) is now unopposed.

This external pressure pushes down on the flexible membrane, forcing it to conform perfectly to the shape of the object inside. This ensures the transfer sheet makes flawless, even contact across the entire surface, including curves, edges, and indentations.

Key Applications and Advantages

The ability to apply perfectly uniform pressure to non-flat surfaces opens up a range of high-value applications that are impossible with standard equipment.

Full-Bleed, Edge-to-Edge Coverage

Because pressure is applied from every direction, designs can wrap seamlessly around the edges and sides of an object. This eliminates the blank margins or faded edges common when trying to press irregular items on a flat press.

Decorating 3D and Irregular Objects

This is the primary purpose of a vacuum press. It excels at transferring high-quality graphics onto items like:

- Phone cases

- Mugs and water bottles

- Plates and ceramic tiles

- Curved photo panels and awards

Superior Dye-Sublimation Results

Vacuum presses are especially effective for dye-sublimation. The even heat and pressure ensure the sublimation inks turn to gas and permeate the object's polymer coating without any gaps or light spots, resulting in vibrant, permanent, and photorealistic images.

Understanding the Trade-offs and Limitations

While powerful, a vacuum press is a specialized tool and is not the right choice for every job. Understanding its limitations is key to making a sound investment.

Slower Cycle Times

The process of arranging items, sealing the chamber, pulling a vacuum, and then releasing it is inherently slower than the simple open-and-close cycle of a standard press. This makes it less efficient for high-volume production of simple flat goods.

Higher Initial Cost and Complexity

Vacuum heat presses contain more complex components, including vacuum pumps, airtight seals, and durable silicone membranes. This results in a significantly higher purchase price and more potential points of maintenance compared to a basic clamshell press.

Material and Size Constraints

The object being decorated must be able to withstand both the heat and the vacuum pressure without deforming or breaking. Furthermore, the size of the product is limited by the dimensions of the machine's vacuum chamber.

Making the Right Choice for Your Production

Your choice between a standard and a vacuum press should be dictated entirely by the products you intend to create.

- If your primary focus is high-volume, flat apparel like t-shirts: A standard press is far more cost-effective and efficient for your needs.

- If your primary focus is premium, custom 3D products like phone cases or awards: A vacuum press is the essential tool required to achieve professional, full-wrap results.

- If your primary focus is maximum versatility for a diverse product line: A vacuum press offers the ability to produce everything a flat press can, plus the added capability of 3D items, justifying the higher investment.

Ultimately, selecting the correct heat press technology is about aligning the machine's capabilities directly with your business goals.

Summary Table:

| Feature | Standard Heat Press | Vacuum Heat Press |

|---|---|---|

| Pressure Application | Mechanical Clamp | Atmospheric Pressure (Vacuum) |

| Best For | Flat Surfaces (T-shirts, mousepads) | 3D & Irregular Shapes (mugs, phone cases) |

| Key Advantage | Speed for High-Volume Flat Goods | Full-Wrap, Edge-to-Edge Coverage |

| Typical Cost | Lower | Higher |

Ready to elevate your product customization with professional-grade results?

A vacuum heat press is the key to unlocking vibrant, full-wrap designs on complex 3D items—a capability that sets premium products apart. Whether you're expanding into phone cases, custom drinkware, or awards, the right equipment is crucial for quality and efficiency.

KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and production facilities. Let our experts help you select the perfect vacuum heat press machine to meet your specific production goals and drive your business forward.

Contact KINTEK today for a personalized consultation and discover the difference the right equipment can make.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What conditions does a Vacuum Hot Pressing Furnace provide for Copper-MoS2-Mo composites? Achieve Peak Densification

- What advantages does hot pressing sintering equipment provide for NASICON? Achieve 100% Dense Solid Electrolyte Plates

- Why is precise temperature control necessary for SiC/Cu Vacuum Hot Pressing? Mastering the Cu9Si Interface Phase

- How does the uniaxial pressing function of a vacuum hot press furnace influence the microstructure of ZrC-SiC ceramics?

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites