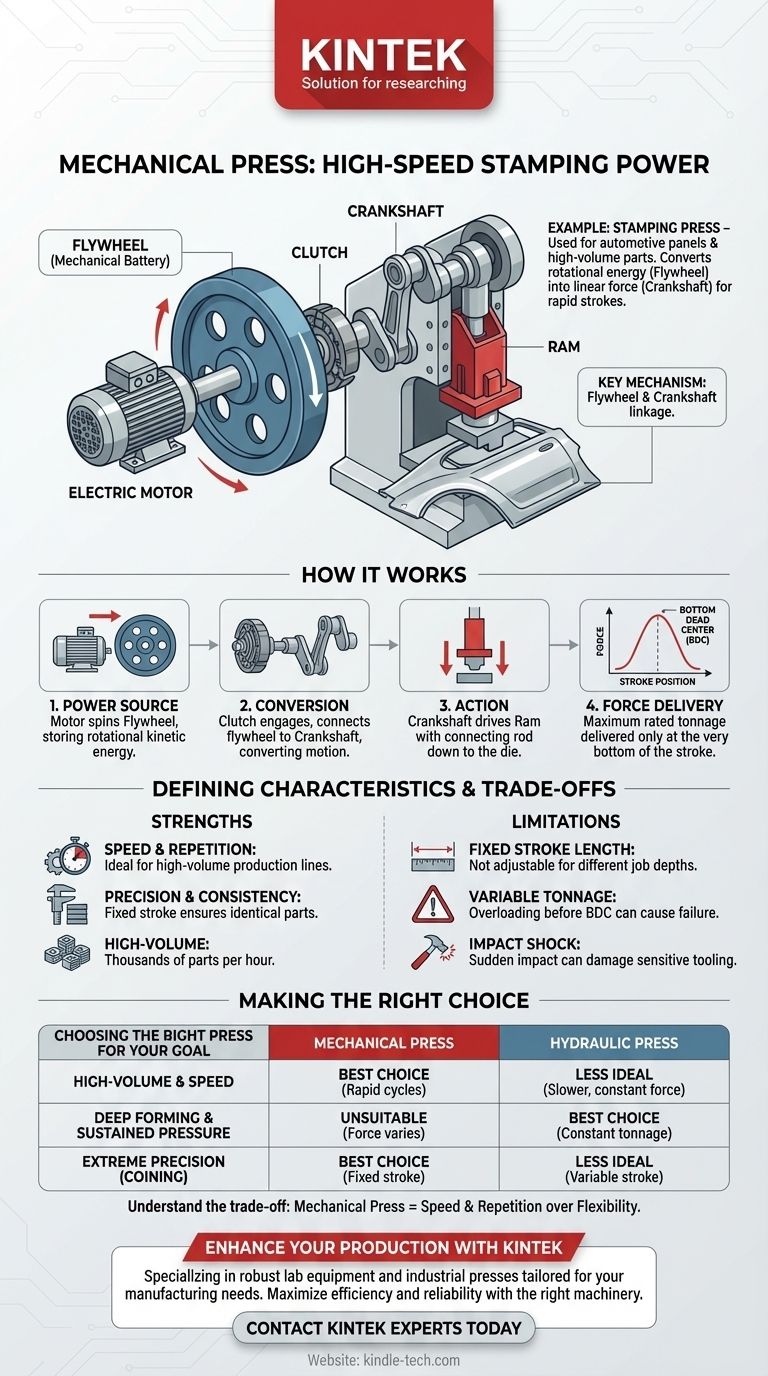

A classic example of a mechanical press is a stamping press, the type used to form sheet metal into automotive body panels, appliance housings, and countless other everyday items. This machine uses the stored energy of a massive spinning flywheel, which is then converted into immense linear force through a crankshaft mechanism, much like the engine in a car works in reverse.

The defining characteristic of a mechanical press is its use of a mechanical linkage—typically a crankshaft or eccentric gear—to convert a motor's rotational energy into a powerful, linear stroke. This design makes it incredibly fast and precise, but it only delivers its maximum rated force at the very bottom of its stroke.

How a Mechanical Press Achieves its Force

To truly understand a mechanical press, you must visualize its core sequence of operations, which is a brilliant application of basic mechanical principles.

The Power Source: The Motor and Flywheel

It all begins with an electric motor. The motor's job isn't to power the stamping action directly, but to spin a very heavy wheel called a flywheel.

This flywheel acts as a mechanical battery, storing rotational kinetic energy. This allows the press to deliver a massive amount of force in a fraction of a second without needing an enormous motor.

The Conversion Mechanism: The Clutch and Crankshaft

When the operator activates the press, a clutch engages, connecting the constantly spinning flywheel to a crankshaft.

The crankshaft is the heart of the machine. Just like in an engine, its job is to convert circular motion into up-and-down (linear) motion.

The Final Action: The Ram and Die

The crankshaft moves a connecting rod attached to the ram (also called a slide). This is the heavy, moving part of the press that holds the upper half of the tool or die.

As the crankshaft completes its revolution, it drives the ram down with tremendous force, stamping, coining, or blanking the material placed in the die before returning to its top position.

Defining Characteristics of Mechanical Presses

The mechanical design gives these presses a unique set of features that make them ideal for certain jobs and unsuitable for others.

Speed and Repetition

Because the action is a simple, continuous rotation, mechanical presses are exceptionally fast. They are the standard for high-volume production lines where thousands of parts must be made per hour.

Precision and Stroke Consistency

The stroke length is mechanically fixed by the design of the crankshaft. This results in extremely high precision and repeatability, ensuring every part produced is virtually identical.

The Force Curve

This is the most critical concept. A mechanical press does not deliver consistent force throughout its stroke. The force is lowest at the top and middle of the stroke and reaches its maximum rated tonnage only at the very bottom, a point known as Bottom Dead Center (BDC).

Understanding the Trade-offs

The strengths of a mechanical press are directly tied to its limitations. Understanding these trade-offs is crucial for any technical application.

Fixed Stroke Length

The distance the ram travels is determined by the physical geometry of the crankshaft. This stroke length cannot be easily adjusted, which limits the press's flexibility for jobs of different depths.

Variable Tonnage

A press might be rated for 100 tons, but it can only safely deliver that force at the very bottom of its stroke. Attempting a job that requires 100 tons of force halfway through the stroke will severely overload the press and can cause catastrophic frame failure.

Impact Shock

The nature of the mechanism creates a sudden, powerful impact at the point of contact. This shock can be detrimental to sensitive tooling or certain types of forming operations that require a slower, more deliberate application of force.

Making the Right Choice for Your Goal

Ultimately, the choice between a mechanical press and its primary alternative, the hydraulic press, depends entirely on the requirements of the job.

- If your primary focus is high-volume production and speed: A mechanical press is almost always the superior choice due to its rapid and consistent cycle times.

- If your primary focus is forming deep parts or jobs requiring sustained pressure: A hydraulic press is better suited, as it delivers its full, constant tonnage throughout the entire stroke.

- If your primary focus is extreme precision in coining or shallow stamping: The highly repeatable fixed stroke of a mechanical press makes it the ideal tool for the job.

Understanding that a mechanical press trades flexibility for speed and repetition is the key to deploying it effectively.

Summary Table:

| Feature | Mechanical Press |

|---|---|

| Primary Example | Stamping Press |

| Key Mechanism | Flywheel & Crankshaft |

| Best For | High-Speed, High-Volume Production |

| Force Delivery | Maximum force at bottom of stroke |

| Stroke | Fixed Length |

Ready to enhance your production line with the speed and precision of a mechanical press?

At KINTEK, we specialize in providing robust lab equipment and consumables, including industrial presses tailored to your manufacturing needs. Whether you're stamping automotive parts or producing high-volume components, our expertise ensures you get the right machinery for peak efficiency and reliability.

Contact our experts today via our Contact Form to discuss how a KINTEK mechanical press can drive your productivity forward.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- What is the hydraulic forging process? Master the Art of High-Strength Metal Forming

- Why is a laboratory hydraulic press used to compress powders into pellets? Enhance Solid-State Reaction Kinetics

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation