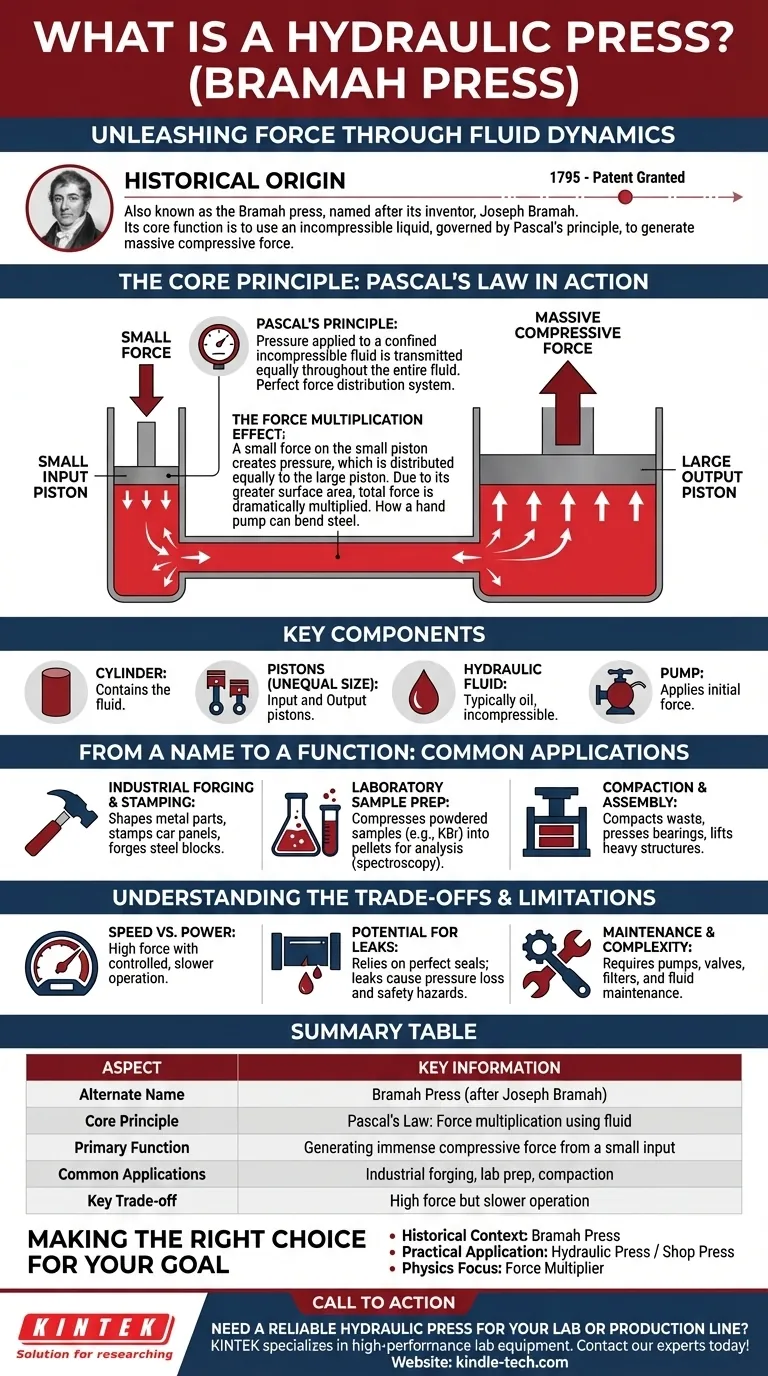

Historically, a hydraulic press is also known as a Bramah press. This name honors its inventor, Joseph Bramah, who patented the device in 1795. The machine's core function is to use an incompressible liquid, governed by Pascal's principle, to generate a massive compressive force from a relatively small initial effort.

The key takeaway is not the name but the underlying principle: a hydraulic press is any device that uses a confined fluid to multiply force. This single concept is responsible for its immense power and widespread use, from industrial forges to scientific laboratories.

The Core Principle: Pascal's Law in Action

To understand why a hydraulic press is so powerful, you must first understand the fundamental law of physics that governs it.

What is Pascal's Principle?

Pascal's principle states that when pressure is applied to a confined, incompressible fluid (like oil), that pressure is transmitted equally throughout the entire fluid.

Think of it as a perfect force distribution system. A push in one spot is felt with the same intensity everywhere else inside the system.

The Force Multiplication Effect

The genius of the hydraulic press lies in using two pistons of different sizes: a small input piston and a large output piston.

A small force applied to the small piston creates pressure in the fluid. Because this pressure is distributed equally, it pushes on the large piston with the same pressure per square inch.

Since the large piston has a much greater surface area, the total force exerted on it is dramatically multiplied. This is how a simple hand pump can generate enough force to bend steel.

Key Components of a Press

Nearly every hydraulic press consists of the same basic parts:

- A cylinder containing the fluid.

- Two pistons of unequal size.

- The hydraulic fluid itself, which is typically an oil.

- A pump to apply the initial force.

From a Name to a Function: Common Applications

The ability to generate tremendous force makes the hydraulic press a cornerstone of many industries and scientific fields.

Industrial Forging and Stamping

In manufacturing, hydraulic presses are used to shape and form metal parts. They can stamp flat sheets of metal into car body panels or forge solid blocks of steel into high-strength components.

Laboratory Sample Preparation

As noted, these presses are vital in scientific labs. They are commonly used to compress powdered samples, like potassium bromide (KBr), with a substance for analysis into a thin, solid pellet for infrared spectroscopy.

Compaction and Assembly

Other common uses include compacting waste materials into dense bales, pressing bearings or bushings into mechanical housings, and even lifting entire bridge sections during construction.

Understanding the Trade-offs and Limitations

While incredibly powerful, the hydraulic press is not the right tool for every job. Understanding its limitations is key to appreciating its design.

Speed vs. Power

The primary trade-off is speed. Hydraulic presses deliver immense, controlled force but are generally much slower than their mechanical counterparts. The movement of fluid simply takes more time.

Potential for Leaks

The entire system relies on perfectly sealed, high-pressure fluid. Any failure in a hose or seal can lead to fluid leaks, causing a loss of pressure and creating a potential safety hazard.

Maintenance and Complexity

A hydraulic system involves pumps, valves, filters, and fluid that must be maintained. Compared to a simple mechanical lever or screw, it is a more complex system that requires regular inspection and service.

Making the Right Choice for Your Goal

Whether you call it a Bramah press or a hydraulic press, identifying it is about understanding its function, not just its name.

- If your primary focus is on the historical context of engineering: Knowing it as a Bramah press shows an appreciation for its origin and inventor.

- If your primary focus is on practical, modern application: It will almost universally be called a hydraulic press or, more informally, a "shop press."

- If your primary focus is on the physics: Think of it as a force multiplier that operates using a confined, incompressible fluid.

Ultimately, understanding the principle of force multiplication through fluid is far more important than memorizing any single name for the device.

Summary Table:

| Aspect | Key Information |

|---|---|

| Alternate Name | Bramah Press (named after inventor Joseph Bramah) |

| Core Principle | Pascal's Law: Force multiplication using an incompressible fluid |

| Primary Function | Generating immense compressive force from a small input |

| Common Applications | Industrial forging, laboratory sample preparation (e.g., KBr pellets), compaction |

| Key Trade-off | High force with controlled, but slower, operation compared to mechanical presses |

Need a reliable hydraulic press for your lab or production line?

KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for precision and durability. Whether you're preparing samples for spectroscopy or require robust industrial compaction, our solutions deliver the consistent force and control you need.

Let us help you achieve your goals with the right equipment. Contact our experts today to discuss your specific application and find the perfect press for your needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy